Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for a way to make your metal parts super smooth and exact? Our cylindrical grinding services can help! We take rough metal parts and make them smooth and perfect for your projects. Let’s learn about this cool process and how it can help your business.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

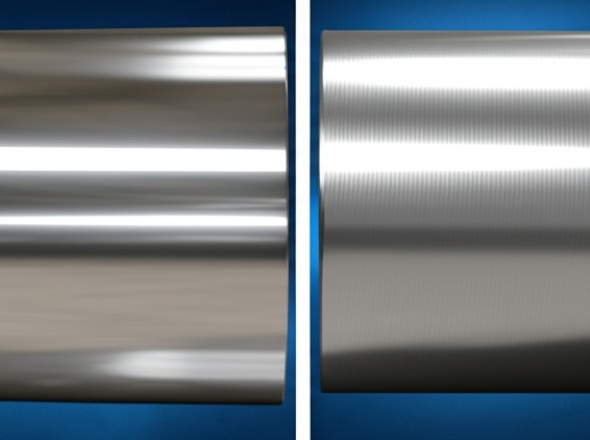

Cylindrical grinding is a special way to make metal parts very smooth. We use special grinding wheels that spin very fast to remove tiny bits of metal from your parts. This makes the parts super smooth and exactly the size you need.

Think about it like sandpaper for metal, but much more exact!

Cylindrical grinding helps when your parts need to:

This is super important for things like car parts, airplane parts, and medical tools that need to work perfectly every time.

We have different ways to grind your parts depending on what you need:

Grinding Type | What It Does | Where It’s Used |

OD/ID Grinding | Makes the outside and inside of round parts smooth | Shafts, hydraulic rods, engine parts |

Surface Grinding | Makes flat surfaces super smooth | Medical devices, precision tools |

CNC Grinding | Uses computers to make very exact parts | Aerospace parts, complex shapes |

Centerless Grinding | For parts that need to be perfectly round | Pins, rollers, needles |

Learn more about our CNC grinding capabilities for computer-controlled precision!

Here’s a simple breakdown of the main materials we work with:

(EN31, EN353)

Hardened steels are super tough! With CBN wheels, we can make mirror-like finishes that last a long time. These materials are perfect when you need parts that won’t wear out quickly.

(Tungsten/Ceramic)

Carbides are extremely hard materials. We use special diamond wheels to grind them with amazing accuracy – down to ±0.001mm! This makes them perfect for tools that need to stay sharp.

These lightweight materials need special care. We use the right cooling to avoid heat damage. The result? Perfect surfaces (Ra ≤ 0.8 µm) for parts that manage heat in electronics.

These tough materials can be tricky! At Istar Machining’s precision CNC machining, we use super-cold cooling to reduce grinding forces by 40% while keeping the material strong.

Titanium is special because it’s both light and strong. We use special coolants to prevent fires and get super smooth finishes (Ra < 0.4 µm) for medical parts.

Let’s compare how these materials perform in cylindrical grinding:

Material | MRR (mm³/s) | Surface Roughness (Ra) | Tool Life (Hours) |

Hardened Steel | 12-15 | 0.3-0.5 µm | 50-70 |

Carbides | 3-5 | 0.1-0.2 µm | 80-100 |

Al/SiC | 8-10 | 0.6-0.8 µm | 30-40 |

Superalloys | 2-3 | 0.4-0.6 µm | 20-30 |

Titanium | 4-6 | 0.2-0.4 µm | 40-60 |

MRR stands for “Material Removal Rate” – how fast we can grind the material.

When we say “exact,” we mean REALLY exact! Our cylindrical grinding services can make your parts within ±0.0001 inches of your requirements. That’s thinner than a human hair!

This is perfect for:

Our cylindrical grinding services help many different industries:

We make parts for airplanes and rockets that need to be perfect. These parts help planes fly safely!

We make engine parts, transmission shafts, and other car parts that need to work smoothly.

Here’s how we make your parts perfect:

Precisely configuring the grinder for your part’s material and tolerances (e.g., ±0.005mm). Select optimal wheel (Al₂O₃/CBN), dress it for concentricity. Calculate and set crucial parameters: wheel/work speed (SFM/RPM), feed rate, and cut depth. Careful setup ensures accuracy from the start.

Securely fixture workpiece between centers or in high-precision chucks (< 0.002mm TIR) for optimal concentricity. Critical alignment verification and appropriate clamping force prevent vibration and distortion. Ensures stability for achieving tight geometric tolerances (cylindricity, roundness).

Material removal using a rotating wheel against the workpiece with controlled feeds. Copious high-pressure coolant prevents thermal damage and aids surface finish (e.g., Ra 0.2µm). A spark-out pass refines final size and finish. Precision grinding achieves exact dimensions.

Crucial in-process and final checks using calibrated instruments (micrometers, CMMs, profilometers). Verify dimensions to micron precision (e.g., ±0.002mm), geometric tolerances (roundness, cylindricity), and surface finish (Ra). Ensures parts meet exact drawing specifications.

Post-grinding steps include thorough cleaning to remove residue and coolant. Optional deburring/chamfering. Application of rust preventative to protect precision surfaces. Careful handling and appropriate packaging ensure parts arrive undamaged and meet final requirements.

Not all grinding services are the same. Here’s what makes ours special:

Our parts are smoother than most others (8-16 μin Ra).

We can make parts within ±0.0001" of your specs.

Get your parts in 1-5 days, not weeks!

We know how to work with hard-to-grind materials.

We help with material selection, design advice, and more.

Choosing our cylindrical grinding services can save you money:

Here are some common uses for our cylindrical grinding:

Part Type | Industry | Why Grinding Helps |

Shafts | Automotive | Makes them turn smoothly in engines |

Hydraulic Rods | Energy | Prevents leaks and makes them last longer |

Bearing Races | Manufacturing | Makes bearings roll smoothly |

Surgical Tools | Medical | Makes tools safe and exact for doctors |

Turbine Components | Aerospace | Helps parts handle high speeds and heat |

Besides grinding, we can also help with:

Getting your parts made is easy:

Send us your drawings (PDF, STEP, or IGES files)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Ready to make your parts perfect? Let our cylindrical grinding experts help you!

Don’t settle for rough or imperfect parts. Choose our cylindrical grinding services and see the difference that perfect parts can make for your business!

A: We can make your parts as smooth as 8-16 μin Ra, which is almost like a mirror!

A: We can handle parts up to 24 inches in diameter and 60 inches long.

A: Rush jobs can be done in 24 hours, and regular jobs take 1-5 days.

A: Yes! We can make just one part or thousands of parts.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or