Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

In this article, we will look at what DFM is. We will see how it can keep you from wasting time, money, and getting upset. You will learn the easy rules of DFM. These rules can change a good product design into a great product that makes money. This is your guide to making things easier to manufacture from the very beginning.

So, what is this thing called Design for Manufacture (DFM)? To say it simply, DFM is the job of designing products so they are easy to manufacture. It is an easy idea, but it is very, very strong. The main goal of DFM is to make the manufacturing process as easy and as cheap as it can be. It is a main part of the product design process. This way of working is sometimes known as design for manufacturing and assembly (DFMA).

Think of it like building with toy blocks. Before you start to build, you think about the blocks you have. You also think about how they fit together. You don’t design a tower that needs a special, one-of-a-kind block you do not have. DFM is the same thing. It makes designers think about the “blocks.” These “blocks” are the tools, materials, and manufacturing methods they can use before they finish the initial design. The concept of design here is to link the creative part of the design process with what a factory can actually do.

The way DFM works is by bringing design engineers and manufacturing engineers together. They talk to each other early in the project and talk often. Talking together helps them find and fix problems with making the product. These are called manufacturability issues. They can fix them way before the product starts being made in the production process. This easy step of working together is the most important part of any good DFM plan to create the best design. This is the main point of design for manufacturability.

In any product development project, a lot of the costs are decided very early in the design process. In fact, studies show that up to 80% of a product’s manufacturing cost is set during the design stage. This is why DFM is so important. If you wait until the design is done to think about how to manufacture it, you have missed a very big chance to save money and time. Implementing DFM changes that.

Without a strong focus on DFM, you can have big problems. A part that is not simple might be hard to manufacture. This can cause mistakes and waste. Using special materials or having very exact measurements can make the manufacturing costs of a product go up. These manufacturing issues can make things late and take away your profit. I have seen projects fail because the cost to manufacture just one part was too high. The initial design looked great on paper but was a huge problem in real life.

A good design for manufacturing process works like a bridge. It connects the design and production teams. It helps make sure the design is optimized for the manufacturing process you choose. The DFM process lowers the number of design changes you need to make later. Fewer changes mean you can get your product to the market faster. It also means your team will be happier. The whole product development journey becomes easier.

To do DFM well, you should follow some easy rules. These principles of design for manufacturing help you make good design decisions. They make things easier for the team who will manufacture the product. I call them the golden rules of smart product design. These key principles make a big difference in how easy and cheap it is to manufacture something.

The first rule is to use fewer parts. When you have fewer parts, there is less to buy and less to keep track of. It also makes for a simpler assembly process. This makes the cost to manufacture lower right away. Another main idea of the DFM principles is to use common parts when you can. Special custom parts cost a lot and take a long time to get. Using common screws, bolts, and brackets will always make it easier to manufacture your product. It will also simplify its manufacturing and assembly process. These design for manufacturing principles are the base for your work.

Here are some of the most important principles of DFM to help guide your work.

| DFM Principle | Why It’s Important | Example |

|---|---|---|

| Make the Design Simple | Fewer parts mean lower cost, an easier assembly process, and less chance for mistakes. | Join two metal parts into one single, stronger part. |

| Use Standard Parts | Common parts are cheaper and easier to find. | Use a common screw size, not a custom-made one. |

| Design for Easy Assembly | Make it very clear how parts go together. Do not use parts that need to be held in a special way. | Use slots and tabs so parts can snap into place. This helps with design for assembly. |

| Use a Modular Design | Design in smaller parts or chunks. This makes putting it together, fixing it, and updating it much easier. | Make a power unit that can be easily taken out and put back in. |

| Choose the Right Materials | Pick materials that are easy to work with for the manufacturing process you have chosen. | If you use injection molding, pick a plastic that flows well. |

The design for manufacturing process is not just one step. It is a group of steps and checks that happen during product development. It starts as soon as you have an idea for an initial design. The first step is to get your designers and manufacturing experts to talk. This main DFM team will work together from the start to the end.

Next, the team does a DFM analysis. They look at the product design and ask hard questions. Can we manufacture this part? Is there a simpler way? What problems might come up? This design review uses DFM tools, like special computer programs or easy checklists. These tools help them see potential manufacturability issues. The goal of this DFM analysis is to find these problems when they are still cheap and easy to fix. The dfm aims to make the manufacture better.

During the DFM analysis, the team checks everything. They look at the shape of the parts, the materials they chose, and the measurements. They check the whole plan for manufacturing and assembly. The result of this DFM analysis is a list of suggestions. The design engineers then use this information to optimize the design. This pattern of designing, checking, and improving goes on until the design is optimized for an easy manufacture. This is what a strong DFM practice looks like.

Yes, it can. This is one of the main goals of DFM. When the manufacturing process is simple, it is cheaper. It is also faster and more dependable. When you design products with DFM in mind, you are actively taking difficult steps out of the production process. You are making life easier for the people who will actually manufacture your product.

DFM helps in a few ways. First, by simplifying the design, you lower the number of steps needed for manufacturing and assembly. Fewer steps mean fewer chances for a mistake. It also means the assembly process is faster. This can directly help increase manufacturing speed. Second, DFM pushes you to use simple, repeatable manufacturing operations. It makes you design parts that can be made with normal tools and machines. This is a main part of design for manufacturing or DFM.

When you streamline manufacturing with DFM, you also have less waste. You use materials in a better way. You have fewer parts that get thrown away. This does not just save money. It is also better for our planet. The whole goal of a good DFM plan is to make an optimal design. This design should move through all the steps to manufacture it with no problems. It removes problems before they can even happen.

When you use DFM practices all the time, you will see great results. The good things you get are much more than just making things easier to manufacture. A good DFM plan can make your whole business better. I have seen companies make a lot more money just by getting serious about their design for manufacturing and design plan.

The first good thing you will see is a lower cost. By making a product easier to manufacture, you directly lower the costs for workers, materials, and the factory. This lower manufacturing cost means you can either sell your product for less, or you can make more profit. Another big plus is getting your product to the market faster. A product that is designed for an easy manufacture moves through the production process much more quickly. There are fewer delays and problems to fix.

Here are some of the key benefits of DFM:

Starting with DFM does not have to be difficult. You can start with small steps. The most important step for implementing design for manufacturing is to start talking early in the design. Get your design engineers and your manufacturing experts in the same room. Let them look at the very first drawings and ideas together.

Make an easy set of design guidelines. This can be a checklist on one page. It could have questions like: Can we use fewer parts? Are we using common screws? Does this part need a special tool to manufacture? These DFM guidelines give your team a shared plan to work with. Make sure every person who is involved in the design of a product understands these basic DFM principles.

You should also give your team training. Teach your design engineers about the different manufacturing process choices they have. When a designer understands how a part is made, they can make better choices. They start to think like a manufacture expert. Building this shared knowledge is very important to make DFM effectively part of how your company works. This is how you build a great DFM program.

Yes, it does, and in a big way. Additive manufacturing, which many people call 3D printing, changes some of the old DFM rules. Old ways to manufacture things, like cutting metal, often work by taking material away. With those ways, complex shapes can be hard and costly to manufacture. But additive manufacturing builds parts layer by layer. This opens up new and exciting things you can do.

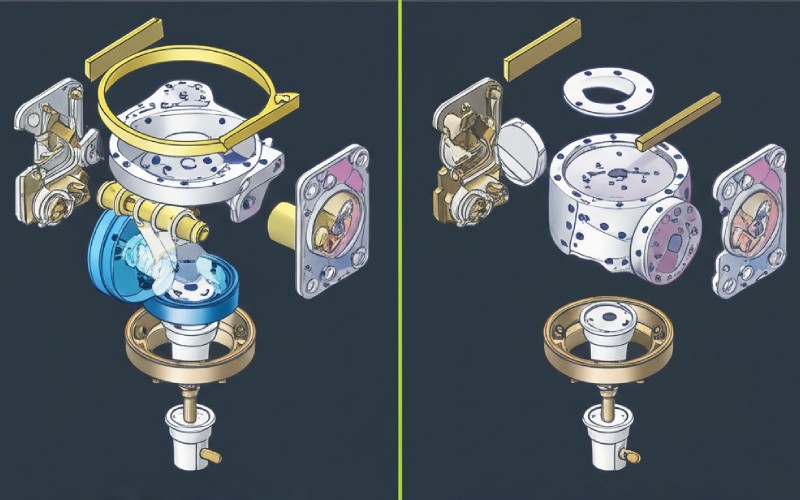

This has made a new area of study called design for additive manufacturing (DFAM). With DFAM, making complex parts costs almost nothing extra. You can make complex shapes on the inside of a part. Or you can join many parts into one single, complex part. That would be impossible to manufacture in any other way. The goal of DFM is still the same. That goal is to make the manufacture as good as it can be. But the exact rules you follow will change.

For example, a key DFM principle is to use fewer parts. Additive manufacturing is very good at this. You can take a group of 10 different parts and print them as one single part. This makes the manufacturing and assembly process much, much simpler. But you also have to think about new things. You have to think about support structures and the direction of the printing. So, the tools are different, but the main idea of DFM is the same. That idea is to design for your specific manufacturing process. It is still very important.

Even when you try your best, things can go wrong. I have seen a few common mistakes that can make a DFM plan weaker. The biggest mistake is waiting too long to start. If you do your DFM analysis after the design phase is almost done, it is too late. The cost of making changes is high. People do not want to go back and start over. A successful DFM starts on the very first day.

Another mistake is when people do not talk to each other. DFM is a team activity. If the designers and the manufacture experts do not talk, the process will fail. Or if they do not listen to each other, it will also fail. The DFM process has to be a partnership where people respect each other. The designers must be ready to hear ideas. And the manufacturing team must give helpful advice. This link between the design and manufacturing processes is very important.

Finally, a mistake is not thinking about the whole life of the product manufacturing. DFM is not just about the first time you manufacture something. It is also about design for assembly, testing, shipping, and fixing it later. For example, a design for six sigma plan thinks about quality for a long time. A good DFM process thinks about all these things. How easy is it to fix the product? How can we make it cheaper to ship? A truly effective DFM looks at the whole picture. These things all affect design for manufacturing.

The final goal of DFM is not just a cheaper product. It is also a better one. To make this happen, your DFM process must care about quality from the start. A good DFM process should ensure the design is not just easy to manufacture. It must also be strong and work well for a long time. This complete approach to product design is very important.

Use your DFM process to make it impossible to make mistakes when you manufacture your product. This is sometimes called “poka-yoke.” You can use design features that stop parts from being put together the wrong way. For example, use a hole pattern that is not the same on all sides. This makes it so a part can only be put on in one way. These small design choices, which are guided by DFM, mean fewer mistakes on the assembly line. This leads to a higher-quality product for the customer.

Finally, you should always keep learning. After you manufacture a product, go back and look at how it went. What parts of your DFM process worked well? What did not work? What could you do better the next time? This way of getting feedback is what makes a good DFM program a great one. It helps you make your DFM guidelines better. It also improves how your design and manufacturing teams work together over time. This constant improvement is how DFM helps you build not just one great product, but many of them. This is how you make sure of the manufacturability of a product and its success.