Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for top-quality parts for your energy projects? At Istar Machining, we make special parts for oil rigs, wind turbines, and power plants. Our 5-axis machining helps create complex shapes that work better and last longer in tough conditions.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Istar Machining makes parts that power the energy world. From tiny valve parts to big heat exchangers, we do it all with amazing accuracy. Our team uses the best machines and tools to create parts that meet all the strict rules for energy equipment.

5-Axis Milling & Turning: We make complex shapes for turbine blades and heat exchangers

ISO 9001-Certified: All our work follows ANSI, API, and ASME rules

Rapid Prototyping: Get test models fast to check your designs

Special Coatings: Our parts resist rust in harsh places like oceans and chemical plants

Tested Materials: We use top-grade metals checked by SGS with RoHS approval

We make special parts for wind turbine machining that last longer. Our energy-smart methods match what green energy companies need.

When you need tough parts for harsh places, our 5 axis machining can make complex drill heads and pump parts while using less power.

Motors, compressors, and hydraulic parts made with our precision cnc machining run better and use less energy when working.

We make frames from aluminum and HDPE that hold solar panels at just the right angle. These materials last for decades in the hot sun without breaking down.

Safety is #1 in nuclear power. Our precision-cut materials meet all safety rules and can work reliably for many years in radiation environments.

Water can be very destructive over time. Our special metals and plastics resist water damage and keep working even after years of constant water contact.

Different materials are better for different jobs. Here’s what works best:

Titanium (Grade 5): The Super Strong Metal

Titanium is light but strong – perfect for parts that need to be tough without being heavy. It fights off rust and can work in super hot places up to 600°C!

Where we use it:

Titanium parts from Istar Machining fit perfectly with other system pieces. This metal is great when your equipment might touch salt water.

Inconel 718: The Heat Fighter

When things get really hot, Inconel 718 is our go-to material. It can handle temperatures up to 700°C without getting weak! This special metal stays strong even when other metals would melt or bend.

Where we use it:

Our team at Istar Machining cuts Inconel with special tools to make sure your parts are perfect.

HDPE (High-Density Polyethylene): The Tough Plastic

This special plastic is super strong for its weight and doesn’t react with most chemicals. We can cut it so exactly that liquids can’t leak through the connections (within 0.1mm!).

Where we use it:

HDPE from Istar Machining stays strong even in bright sunlight for years and years!

Stainless Steel 316L: The Rust Fighter

This special steel never rusts, even in the toughest conditions. It stays strong and doesn’t pit or corrode when around salt water.

Where we use it:

Our Istar Machining team cuts stainless steel to exact shapes that work perfectly in harsh places like ocean platforms.

PEEK Thermoplastic: The Electrical Helper

PEEK is a special plastic that can handle heat up to 250°C and doesn’t let electricity pass through it. It also doesn’t catch fire easily, making it safe for electrical parts.

Where we use it:

At Istar Machining, we shape PEEK to fit perfectly in solar power controls and geothermal measuring tools.

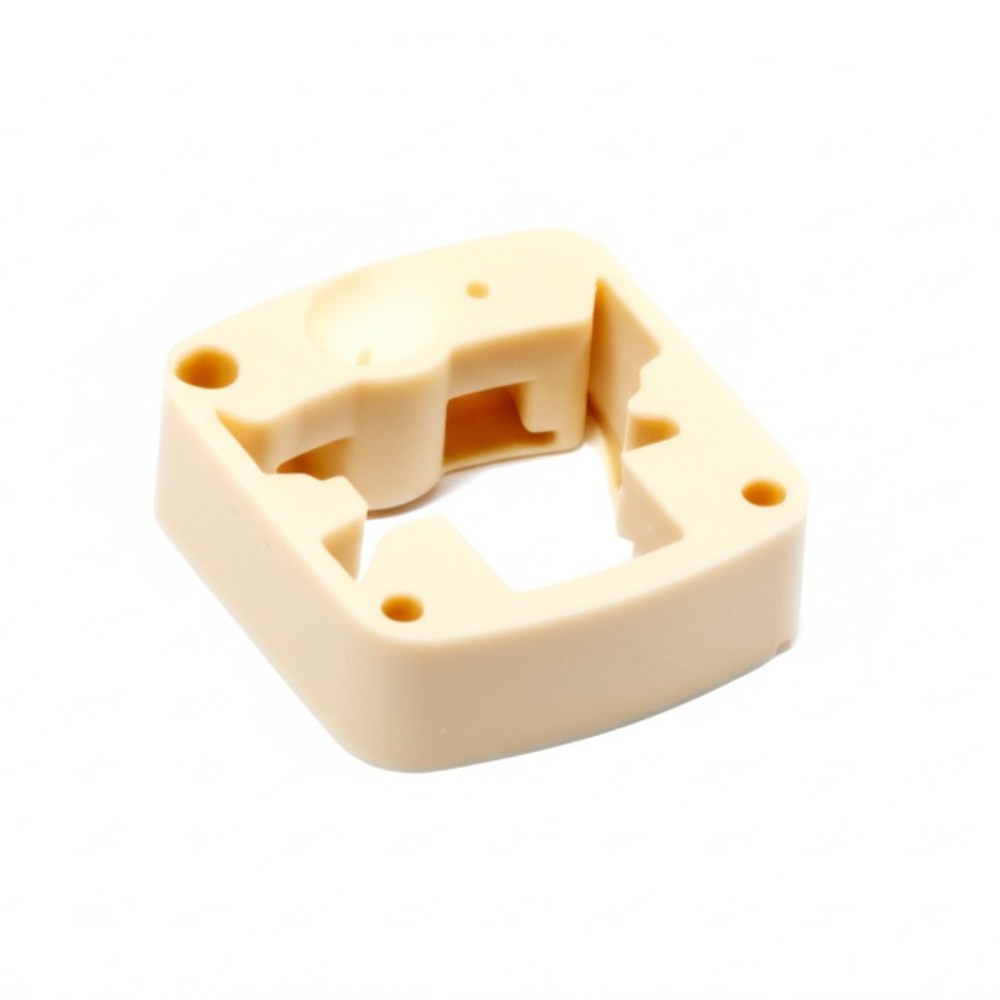

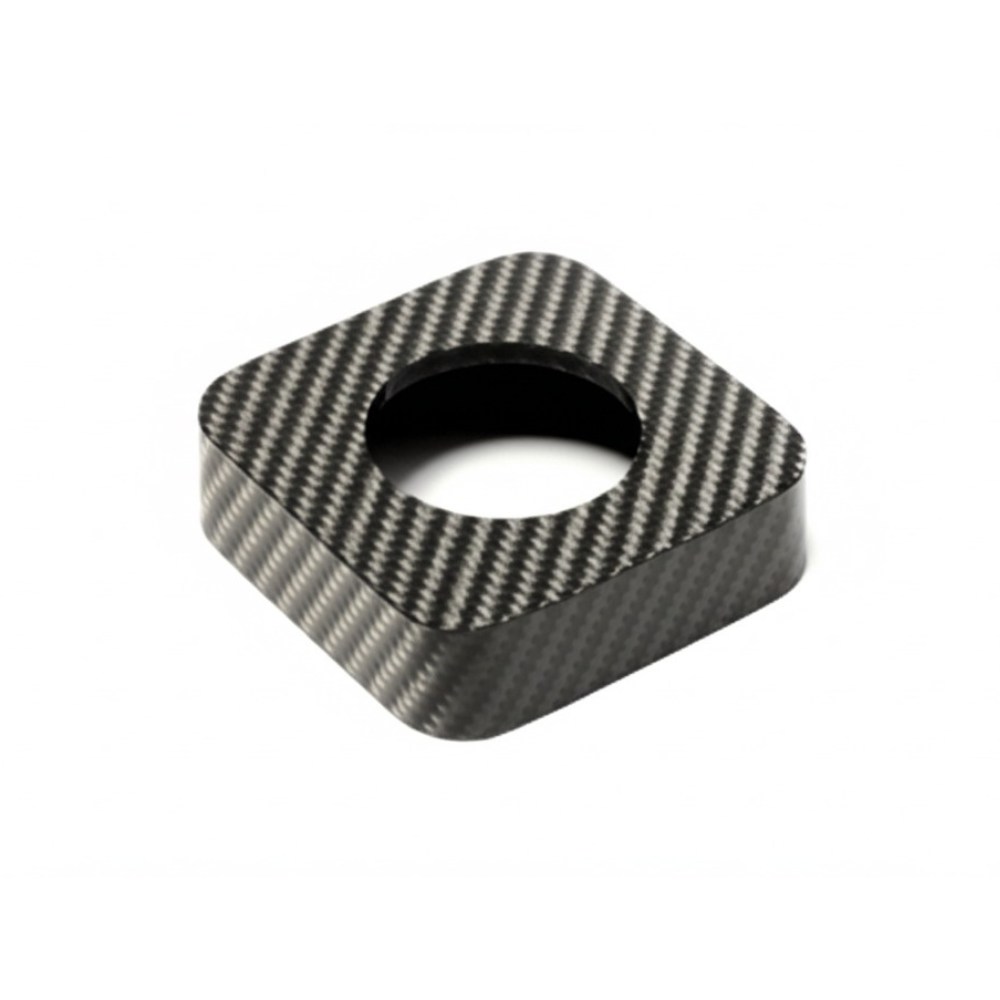

Carbon Fiber Composites: The Ultra-Light Champion

These materials are five times stronger than steel but much lighter! They don’t get tired and break even when used over and over again.

Where we use it:

Our Istar Machining carbon fiber parts help wind turbines spin more easily while staying super strong.

Material | Best Features | Perfect For | How Strong |

Titanium (Grade 5) | Fights rust, handles heat | Ocean drilling, turbines | 550 MPa (very strong) |

Inconel 718 | Works in extreme heat | Nuclear parts, gas turbines | 1,100 MPa (super strong) |

HDPE | Doesn’t react with chemicals | Solar mounts, pipes | 7.5 kJ/m² impact strength |

Stainless Steel 316L | Never rusts, even in salt water | Oil rigs, outdoor hinges | 485 MPa tensile strength |

PEEK | Stops electricity, handles heat | Battery cases, sensors | 19 kV/mm electrical resistance |

Carbon Fiber | Lighter than metal but stronger | Wind turbine parts, robots | 5x stronger than steel |

Aluminum 6061-T6 | Easy to work with, light | Solar frames, turbine houses | Good machinability |

Copper-Nickel | Fights growth in sea water | Water systems, drilling | 29 W/m·K heat transfer |

Expert Material Knowledge: We help you pick the right material for your exact needs

Perfect Precision: Our machines cut with amazing accuracy

Fast Delivery: Get your parts when you need them

Tested Quality: Every part passes strict tests

All Your Needs: From small sensor parts to big turbine pieces

Explore our offshore energy solutions for specialized materials that withstand harsh marine environments.

At Istar Machining, we’re ready to help with your energy project. Whether you need one special part or thousands of pieces, our team will:

Help choose the right material

Design the perfect part

Make it with exact measurements

Test it thoroughly

Deliver it on time

Contact us today to learn how our materials can make your energy projects better, stronger, and more efficient!

Request a free quote for your CNC machining needs and experience the Istar difference.

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Our machines use better cutting paths and don’t waste time running when not cutting. Think of it like a car with start-stop technology at red lights.

Yes! We make parts certified for both solar and wind systems using special tools approved by the makers.

We can make test parts in 5 days. Bigger orders take 2-3 weeks, which is faster than most other shops.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or