Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Learning the real difference between strength, stiffness, and hardness is a very important lesson. It is important for every designer or engineer. It is the best way to pick the right material for the job.

I wrote this article for you. It will help if you have ever been confused by these words. I am going to explain these main mechanical properties. I will do it in a simple way. You will learn what each term means. You will see why they are not the same. And you will understand how they help you make better choices in your engineering design work. I promise there is no hard math. I will use only simple English. This will help you learn these basic ideas.

Let’s start at the very beginning. So, what are mechanical properties? You can think of them like a material’s personality. These properties tell us how a material will behave. For example, what happens when we push it, pull it, or try to scratch its surface. We must understand these properties. This helps us know if a part will bend, break, or wear down over time.

For any type of engineering design, this is some of the most important information to have. When you know the material properties, it is like you have a secret code. This knowledge helps you pick the best material for your project. Do you need a part that can hold a heavy weight without breaking? You need to look at its strength. Do you need a part that will not bend or flex? Then you need to care about its stiffness. Do you need it to resist scratches and dents? That is all about hardness. Making the right choice here is the basis for good design engineering.

Strength is a fundamental property of a material, which means it is a very basic one. In a simple way, material strength tells you how much force a material can handle. It’s the limit before it either bends for good or breaks. Strength indicates the maximum stress a material can withstand. When you stress a material, you are putting a load on it. If the load is too big, the material will fail.

There are different types of strength. For example, compressive strength shows how well a material can stand up to being squeezed. Tensile and yield strength explain what happens when you pull it apart. The main idea is that strength is about the amount of load a material can withstand. It is the limit before something bad happens, like a permanent change in shape, which is called deformation. A material with high strength can resist a large force without breaking. The strength of the material is a very important number. You will find it on any material data sheet.

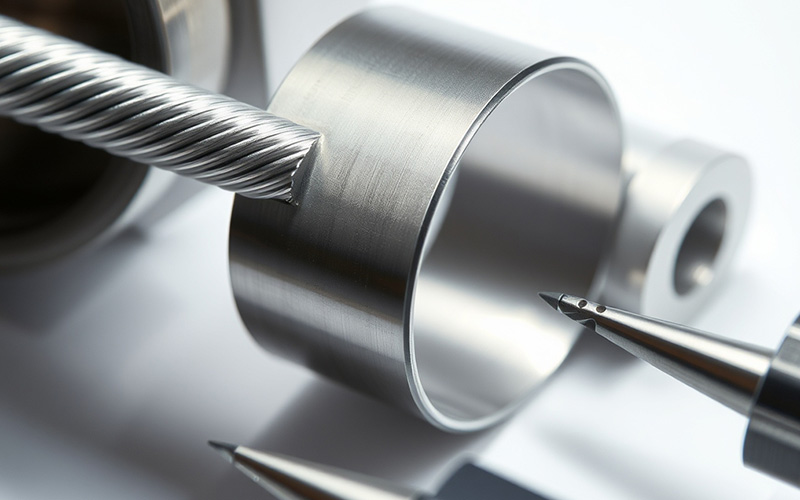

This is where a lot of people get mixed up. They think stiffness is the same as strength. It is not! The difference between strength and stiffness is a very important thing to know. Stiffness is how well a material resists bending or stretching. This happens when a force is put on it. It is not about the material breaking. It is about its change in shape, or deformation. A material with high stiffness does not bend or flex easily.

Let me give you an example. A glass rod has high stiffness. It is very hard to bend. But its strength is low. If you try to bend it too much, it just snaps. A rubber band has very low stiffness. It stretches easily with little force. But it might be quite strong and hard to break. The main idea of stiffness is all about resisting deformation. So, when you need a part to hold its shape under a load, you are looking for high stiffness. We can also talk about different types of stiffness. These include bending stiffness, torsional stiffness, and shear stiffness. The stiffness of an object is a very important part of its design.

Now we can talk about hardness. Hardness is very different from strength and stiffness. Hardness is a measure of how well a material resists changes to its surface. This means how well it stops scratches, dents, or general wear. A diamond is a perfect example. It has very high hardness. You can use a diamond to scratch almost any other material.

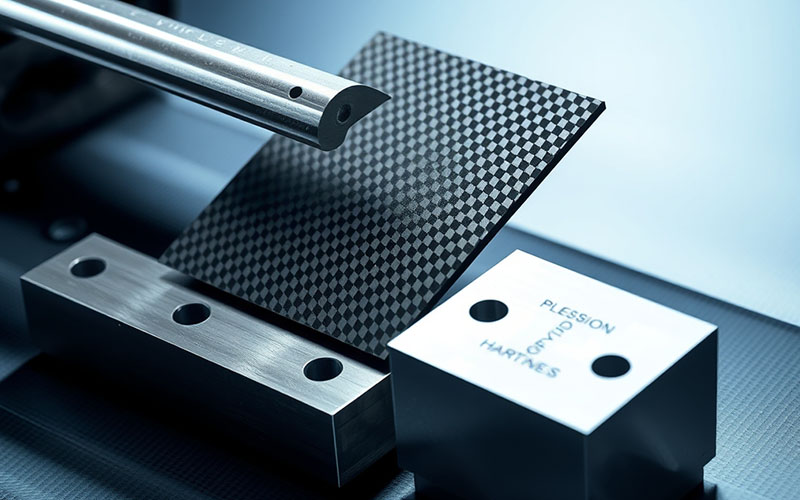

Hardness measures a material’s ability to resist permanent changes in shape in a small area. This is also known as localized plastic deformation. We often do hardness testing to find out this value. You might have heard of tests like the Rockwell or Vickers hardness tests. These tests work by pressing a small, hard point into the material’s surface. Then, they measure the size of the mark that is left. Higher hardness is important for parts that rub against each other. It is also important for cutting tools used in things like CNC machining. A material’s hardness is its first protection against damage to its surface.

So, how can we measure these properties? Engineers use a very useful tool called a stress-strain curve. Let’s picture this. We take a small piece of a material and pull on it. We measure the force we are using (stress). We also measure how much the material stretches (strain). If we put those points on a chart, we get a stress-strain curve. This one chart gives us a lot of information.

The chart shows how a material acts when a load is on it. In the beginning, when we pull, the material will stretch. But it will go back to its original shape if we let go. This is called elastic deformation. The steepness of the line in this first part tells us about the material’s stiffness. If the line is steeper, the stiffness is higher. If we keep pulling, we get to a point where the material starts to stretch permanently. This is plastic deformation. The point where this permanent stretching begins is the yield strength. The peak of the stress-strain curve is the ultimate tensile strength. After this point, the material will break soon after. So, a single stress-strain curve shows us both strength and stiffness.

Let’s look more closely at two numbers from the stress-strain curve: yield strength and ultimate tensile strength. Knowing the difference between tensile strength vs yield strength is very important for making safe designs. The yield strength is the amount of stress that makes a material change from temporary stretching to permanent stretching. In other words, it is the point where the material bends and stays bent. It will not go back to its original shape. This is the yield point.

The ultimate tensile strength is the maximum stress a material can take while being pulled. After this point, it begins to get thin and then break. You might think this is the most important number. But for a designer, the yield strength is often more important. Why is that? Because you normally do not want your parts to permanently bend while being used. Once a part has gone through plastic deformation, it has failed its job. So, we usually design parts to make sure the stress on the material is always less than its yield strength of the material.

When engineers talk about stiffness, they use a special number. This number is called the elastic modulus, or Young’s modulus. This modulus is a measure of a material’s stiffness. It is a very basic and important key material property. The elastic modulus is figured out from the stress-strain curve. It is the steepness of the straight part of the curve. A material that has a high Young’s modulus also has a very steep line. This means it has high stiffness.

So, when you look at a material data sheet, the elastic modulus (or Young’s modulus) is the number that tells you about its stiffness. A bigger number means more stiffness. It means the material will resist deformation better. For example, steel has a much bigger modulus than aluminum. This means steel has a higher stiffness. This modulus is a basic value for the material itself. It does not change with the part’s shape. This makes it a true material property that gives a number for material stiffness. The relationship between stiffness and the modulus of elasticity is direct and clear.

This is a common question in engineering applications. The answer is always: it depends on the job you need to do. The question of strength vs stiffness is a choice you must make. Are you designing a hook for a large crane? The hook must hold a very heavy weight without breaking. In this case, strength is the most important property. You need to find a material with a high yield strength. You care about the total load a material can handle.

But what if you are designing the floor for a new building? You do not want the floor to feel bouncy when you walk on it. It needs to resist bending and deformation from the weight of people and furniture. For this job, stiffness is more important than strength. You would pick a material that has a high elastic modulus. Stiffness and deflection are opposites. High stiffness means a small amount of bending. The purpose of material selection is to find the material with the correct mix of strength and stiffness for your project.

| Application | More Important Property | Why? |

|---|---|---|

| Car Bumper | Strength (Toughness) | Must absorb energy in a crash without shattering (needs deformation). |

| Aircraft Wing | Stiffness | Must not flex too much under air pressure to keep the plane stable. |

| Engine Piston Rod | Strength | Must handle huge forces from combustion without permanent deformation. |

| Bookshelf | Stiffness | Must not sag (show deformation) under the weight of books. |

This is another thing people often get wrong: stiffness vs hardness. People often think that a hard material has to be stiff too. Sometimes this is true, but not always. You should remember that stiffness is about resisting bending (deformation). On the other hand, hardness is about resisting scratches and dents on the surface.

Let’s think about a ceramic tile for a floor. It has very high hardness. It is very hard to scratch. It also has very high stiffness; it does not bend at all. In this situation, both stiffness and hardness are high. Now, think about a piece of spring steel. It has very high stiffness, but its hardness might be less than the ceramic tile. You can design a material to have a very hard coating on the surface but have a center with lower stiffness. The two properties explain different ways the material acts. When you are doing material selection, you have to think about them one by one.

So, where can you get all this information? You cannot just guess these values. You need reliable material data that you can trust. The best places to find it are in engineering handbooks. These big books are full of charts and tables of material properties for all the common metals, plastics, and ceramics.

Another great place to look is the data sheets that the material sellers give you. When you decide to buy a certain type of steel or aluminum, the maker will give you a sheet. This sheet will list its yield strength, ultimate tensile strength, elastic modulus, and hardness. You must learn how to read these data sheets with care. Finally, groups like the American Society for Testing and Materials (ASTM) make the rules for how to test these properties. This helps make sure that when one company reports the hardness of their steel, it can be compared with information from another company. Always use data from a source that you know is trustworthy.

I know we talked about a lot of things, but I want you to leave with a very clear idea of the basics. Here are the most important points to remember.