Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

People often use “engineering drawing” and “CAD drawing” to mean the same thing. But they are different. Knowing the difference is very important. In this article, I am going to explain it all for you. I will use my own stories to show you what each word truly means. You will see how they connect to each other and why this is important for your project. This knowledge will help you speak more clearly to your team. It will also help you stop mistakes before they happen and make your design work go much more smoothly. It is a small piece of information with a big payoff.

Let’s begin with the basics. Before we can talk about CAD or an engineering drawing, we must understand the term technical drawing. You can think of a technical drawing as a special kind of picture. It has a very important job to do. Its job is to share a plan. It shows how something should be made. The plan could be for something simple, like a wood chair. Or it could be for a complex part for a machine.

The main goal is always the same. A technical drawing must give instructions that are very clear. This kind of drawing is like a language that all builders and makers can understand. It uses lines, symbols, and numbers to share an idea perfectly. When a designer makes a good technical drawing, a person in a factory far away can look at it and know just what to do. The drawing is the link between the idea and the real thing. Without a good drawing, making things would be all guesswork.

Now, let’s get into the details. An engineering drawing is a very special kind of technical drawing with a lot of detail. I like to imagine it’s a technical drawing that went to school and got a special certificate. It must follow a very strong set of rules. These rules decide everything. They decide how thick the lines are, what views of the part are shown, and how every single size, or dimension, is written. There is no room for guessing.

An engineering drawing is all the papers and information needed for one part or product. It has every single detail you need for manufacturing. This includes the type of material to use and how the surfaces should feel. It also lists how much a dimension can be off by and still be okay. This amount of detail makes an engineering drawing more than just a picture. It is a legal paper. If a part is made the wrong way, everyone looks at this drawing to find out what went wrong.

This is where a lot of people get mixed up. When they hear “CAD,” they think it is just another name for a drawing. That is not quite correct. CAD stands for Computer-Aided Design. The important word here is “Aided.” This means CAD is a tool. It is a way you use to make a drawing. It is not the drawing itself. A long time ago, the tool was a pencil and a big piece of paper. Now, the tool is a computer that has special software.

So, if a person says they work in CAD, it just means they use computer software to make their designs. The CAD software is the new version of a drafter’s table. It is a very strong tool that has changed how we design things. But it’s good to remember that you can make many things with CAD. You can make art, movies, and of course, a very accurate engineering drawing. The CAD itself is the tool, not the thing you make at the end. What you make might be a CAD drawing.

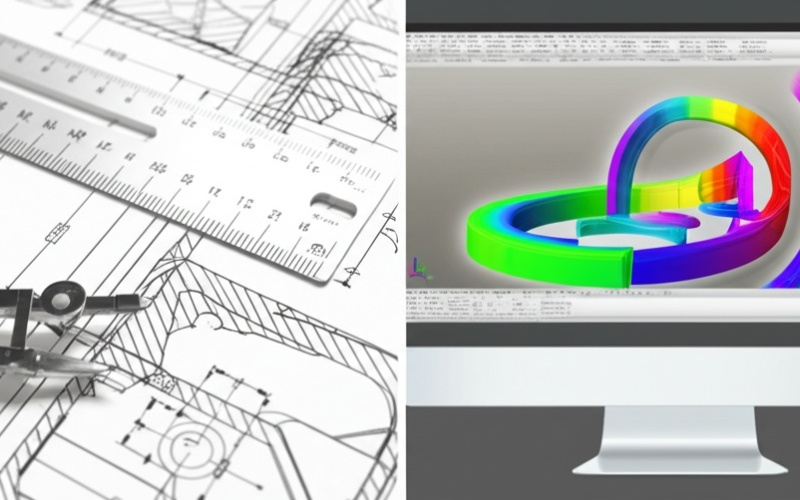

The way you make a drawing is very different when you compare the old way with the new way. The old way is drawing by hand, or manual drawing. This means you are creating a drawing with your hands. I remember using tools like t-squares, a protractor, and special pencils. I used them to draft a design on a big board. It was a hands-on job that needed a lot of skill and took a long time. Every line had to be drawn with great care.

The CAD way is all done on a computer. A designer uses a mouse and keyboard to make the drawing on a screen. The computer software takes care of drawing straight lines and perfect circles. This digital process is much faster. It is also easier to fix mistakes than the manual way. You do not have to worry about smudging your lines or making a mistake you cannot erase. This difference in the process is why working with a CAD drawing saves so much more time and effort.

When we look at drawing vs. CAD, being accurate is a big subject. With a drawing done by hand, how good the designer is sets how accurate it is. Even the best person can make a small human error. A line might be a little bit off, or a measurement could be read wrong. These small mistakes can lead to big issues when making the part. Getting a very exact measurement by hand is hard.

This is where CAD has a very big benefit. CAD software is made to be very exact. When you draw a line, you can tell the computer to make it exactly 50 millimeters long. Not 50.1 or 49.9. Exactly 50. This level of precision is almost impossible to get by hand. Because the software does the math, the chance of human error in the shapes and sizes in the drawing is much, much lower. This helps make the final product right and creates less waste. The CAD design process helps make sure quality is high.

| Feature | Manual Engineering Drawing | CAD Drawing |

|---|---|---|

| Tool Used | Pencils, T-squares, paper | Computer software (CAD software) |

| Accuracy | Depends on designer’s skill | Very high, figured out by computer |

| Precision | Limited by what a hand can do | Almost perfect, set by software |

| Speed | Slow, needs careful work | Fast, has tools to create things fast |

| Making Changes | Hard, need to erase and redraw | Easy, can change and save new copies |

| Working with a Team | Hard, have to share the real paper | Easy, can send digital files right away |

Modern CAD software can do a lot more than just help you make a 2D drawing. Its best feature is making a 3D model. This is a computer version of the product. You can spin it around and look at it from any side you want. This 3D model is full of information. You can check how different parts fit with each other. You can test how strong they are. You can even see how air or water will move over them, all inside the computer.

This ability to build and test a digital model has changed how we design products. In the past, you had to build a real model to test your design. This was slow and cost a lot of money. Now, you can do most of that testing on a computer using CAD models. This helps designers find problems early in the process. It helps them improve their design and make a better product in less time. The software gives a much better understanding of a design before you build anything real.

I believe anyone who has made a drawing by hand will say that making changes is the hardest part. If a key person wants a big change, it could be a really hard job. A big change might mean you have to throw away the whole drawing and begin all over. Even a small change needs you to erase carefully. This can hurt the paper and make the drawing look messy. The process of making changes was something nobody liked.

With a CAD drawing, it is so much easier to make changes. You just pick the feature you want to change and type in a new dimension. The software fixes the drawing for you. You can move a hole, make a part longer, or change a material very quickly. You can save different copies of the design to look at different ideas. This freedom makes the design process flow better and lets you be more creative. This benefit of saving time and work is a big reason why almost everyone uses CAD now.

Now we can answer the most important question. Is a CAD drawing the same thing as an engineering drawing? The answer is: sometimes it is. This is the main point you need to know. An engineering drawing is known by what’s in it—the rules, standards, and all the details it follows. CAD is known by the tool you use to make it.

You can use CAD software to make a complete and proper engineering drawing. When you do that, the final drawing is a CAD drawing and an engineering drawing. But you could also use CAD to make a quick sketch. That sketch would not be a real engineering drawing because it doesn’t have all the needed papers and details. In the same way, you can make a perfect engineering drawing by hand. You can do it without ever using a computer. That would be an engineering drawing, but it would not be a CAD drawing. Think of it this way: a “novel” is a kind of book, and a “printing press” is a tool to make one. CAD is the tool; the engineering drawing is the special kind of book.

If you are starting a new design project, choosing to use CAD is an easy decision. The good things about it are just too big to pass up. I have seen with my own eyes how much it can make the whole work process better, from the first idea to the finished product.

Here are some of the biggest benefits I have seen:

In the world we live in today, the choice is almost always CAD. For any big project that will be made in a factory, a CAD design is the normal way. The accuracy, speed, and power to make a 3D model are very needed for designing products today. Of course, to use CAD, you need to spend money on software and learning how to use it. This is something some people need to think about.

Does this mean there is no reason to make a drawing by hand? I do not think so. A quick sketch by hand is still one of the best ways to get a new idea out of your head and on paper. For a very first try or for thinking up new ideas, a pen and paper are a great tool. But as soon as that idea needs to become a real design with exact sizes and details, it is time to switch to CAD. The hand drawing is for the first spark of an idea; the CAD drawing is for building the real thing.