Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

The world of making things has its own special language. It can be hard to understand if you are new. It can also be hard if you work with people in a plant or factory. This guide is here to help you. We will explain the most important manufacturing terms in a simple way. This is not a full dictionary of terms, but it explains the main ideas.

When you read this article, it will help you talk with your team. You will understand how things are made. You will do your job better. This is your easy guide to understanding the manufacturing industry. Let’s look at the important words and what they mean.

Think of a Bill of Materials, or BOM, as a recipe. A recipe tells you everything you need to bake a cake. A BOM tells you everything you need to build a product. It is a list. It shows every raw material, part, and group of parts you need. It shows the exact number of each item. This list is a very important part of the manufacturing process.

The BOM makes sure that everyone knows what parts needed to make the finished product. The product design team makes the BOM. The buying team uses it to order all the materials. The production team uses it to build the product. A BOM that is correct helps the production process go well. It is a main paper for any job where things are made. The specification or details for each part is very important.

Here is a simple BOM for a skateboard:

| Part Number | Part Name | How Many | What It Is |

|---|---|---|---|

| SKD-001 | Skateboard Deck | 1 | 32-inch maple wood deck |

| TRK-002 | Truck Assembly | 2 | Standard metal trucks |

| WHL-003 | Wheel | 4 | 54mm urethane wheel |

| BRG-004 | Bearing | 8 | Standard skate bearing |

| HDW-005 | Hardware Pack | 1 | 8 bolts and 8 nuts |

Sometimes, a product needs to be changed. Maybe a part is not strong enough. Maybe a cheaper material is found. When a change is necessary, someone fills out a form. This form is called a change request. People also call this form an engineering change request. It explains the change someone wants to make. It also explains why the change is needed. This is the first step in the engineering change process.

A team then looks at the change request. The team decides if the change is a good idea. They look at how much it will cost. They also look at how it will change the quality of a product. This check is a key part of the production process. A good system for handling a change request stops mistakes from happening on the plant floor. Making a change without a proper change request can cause big problems in the manufacturing process.

Good Manufacturing Practice, or GMP, is a system. It makes sure that products are always made with good quality. GMP covers everything. It includes the materials used and the training of workers. It helps to reduce problems that you cannot find just by testing the final product. Good manufacturing is very important for things like food and medicine.

Companies that follow GMP have a strong system of rules. They have a clear operating procedure, or set of steps, for every job. They keep very good records. These records show that the right steps were followed in the manufacturing process. In many industries, manufacturing plants receive certification attesting that they follow GMP. This means their stated quality processes are adhered to. This helps customers trust them. A good manufacturing practice is very important for safety and quality.

Mistakes can happen. When there is a problem, you need a plan to fix it. This is where a corrective action plan is used. It is often called CAPA, which means Corrective and Preventive Action. The goal is to fix the problem. It is also to stop the problem from happening again. This is a big part of quality management.

First, you must find the real reason for the problem. Why did it happen? Once you know the reason, you can make a plan for corrective action. This plan lists the steps to fix the problem. It also includes steps to stop the problem from happening again in the future. Following a corrective action plan is a key part of always getting better, which is called continuous improvement. Good records, like reject reason codes, help find what needs to be fixed.

If a change request is approved, the next step is an Engineering Change Order (ECO). An ECO is a special paper. It tells exactly what the change is for a part or product. It tells people what to do. This includes changes to the Bill of Materials, drawings, or the manufacturing process.

The ECO makes sure the change is done in the right way. It is an official part of the production process. It tells the team what new materials to use. It explains any new steps in the operating procedure. The engineering change order helps watch and manage the product design from the start to finish. An engineering change is not finished until the ECO is given out and followed. A weak change request system can lead to a messy ECO process.

Takt time is how fast you need to make a product. This speed is decided by customer demand, or what customers want. Think of it as the heartbeat of your production line. If you have 8 hours to work and customers want 480 products, your takt time is one minute. This means one finished product must be made every minute to meet customer demand.

Understanding takt time is a key idea in lean manufacturing. It helps you see if your production process is fast enough. It is not the same as cycle time. Cycle time measures the actual cycle time it takes to do one job. The goal is to make your cycle time shorter than or equal to your takt time. A manufacturing analytics software can calculate this. The average time to make a product should be close to the ideal cycle time. This helps make lead times shorter.

A Quality Management System, or QMS, is a group of rules and ways of doing business processes. These rules are all about giving customers what they want and making a good product. A QMS helps a company set up its manufacturing operations to get good quality every time. It is a formal system that guides the whole company. It is a series of standards.

A good QMS has many parts:

A strong quality management system helps a company find and fix problems early. This makes the quality of a part better. When attesting that their stated quality is high, a company can show its QMS. It is the foundation for making a great manufactured product.

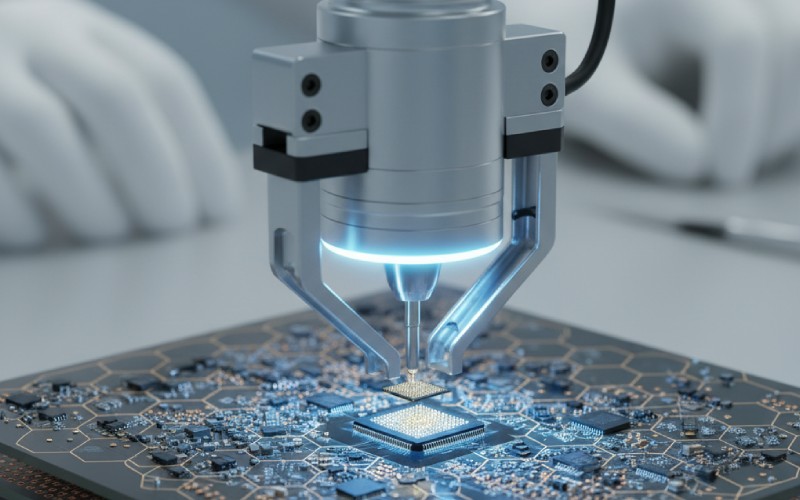

Computer-Aided Manufacturing (CAM) is the software used to tell machines what to do. It is a type of manufacturing technology. First, a designer makes a 3D model of a part on a computer. Then, CAM software uses that model to create a list of instructions. These instructions tell a machine exactly how to cut, drill, or shape the raw material.

CAM is very important in today’s manufacturing. It lets companies make difficult parts very accurately. It makes the manufacturing process faster. It also helps make products the same way every time. CAM software takes input data from the design. It turns that data into real movements for the machine. It is often used with computer-aided design (CAD) software. This is one of the terms used a lot in the manufacturing industry.

Industry 4.0 is the name for what is happening now in manufacturing. It is about using machines and sharing information in new ways. Some people call it the “fourth industrial revolution.” It connects machines, people, and information. This is very different from a traditional manufacturing strategy. It is all about making factories “smart.” A key part is the “communication of real-time plant data.”

Key ideas in Industry 4.0 are:

Industry 4.0 helps companies keep track of product counts as they happen. It also helps them determine the quality of products as they are being made. The real-time plant data between control systems makes this happen. This uses plant data between control devices to improve the machine processes in a plant. A manufacturing analytics platform is a key tool for this.

The manufacturing industry uses a lot of short names, or an acronym. Here are two important ones. This is not a full manufacturing glossary, but it gives you a start on key industry terms.

SMED stands for Single-Minute Exchange of Dies. This is a key idea in lean manufacturing. It is a manufacturing methodology with the goal of making the time to change a machine shorter. When you change a machine from making one product to another, you want it to be fast. The goal is to make this change take less than 10 minutes. Quick changes mean less time when nothing is being made. The production time is used for making products, not for waiting. This is a method that used manufacturing teams use to be more efficient.

RoHS stands for Restriction of Hazardous Substances. This is a rule that started in Europe. It limits the use of certain dangerous materials in electronics. Companies that sell electronics in Europe must show that their products meet RoHS quality standards. This is important for protecting the earth and keeping people healthy. It is one of the most important manufacturing terms and definitions for companies that make electronics.

Here is a short list of the most important ideas from this guide to manufacturing terms and definitions. These are essential manufacturing ideas.