Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

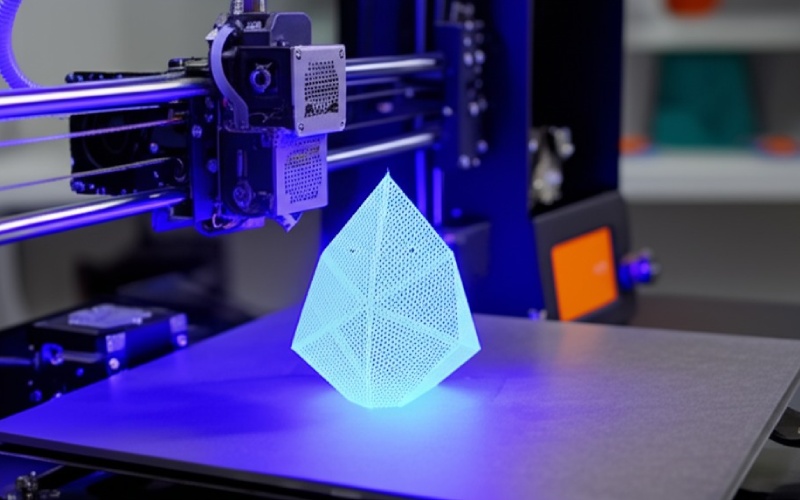

I remember the very first time I saw a 3D printer. It was at a big show many years ago. It was a little box. Inside the box, a small tip was moving around, building a tiny plastic frog. It seemed like it was making it from nothing. It looked like magic. That magic was a 3d printing technologies known as Fused Deposition Modeling, or FDM. Today, FDM is one of the most popular ways to make a 3d print.

In this article, I am going to show you how that magic works. I will explain what FDM 3D printing is and how you can use it. I will also tell you why it might be the best tool for what you want to make. You will learn about the good things and the not-so-good things about it. When you finish reading, you will understand this really cool fdm technology. You will also know how it can take a file on a computer and make it into a real object you can pick up.

So, what is Fused Deposition Modeling? You can think of it as a very smart hot glue gun that is super neat. It is a kind of additive manufacturing. That is a fancy way of saying you build things by adding material. You are not cutting material away, like you would if you were shaping a block of wood. The printer uses a long cord of plastic, which is called a filament. The printer melts the filament and then draws your object, one very thin layer at a time.

This way of building things layer by layer is what makes a 3d print happen. The printer puts down one flat piece of your object. That piece cools and gets hard. Then, the printer puts the next piece on top of that one. It does this again and again. After hundreds or thousands of layers, you have a complete 3d print. This method is the main idea behind FDM 3D printing. It uses a thermoplastic material. A thermoplastic is a kind of plastic you can melt and cool many times, and it will still be good.

The path from an idea to a real 3d print is a very interesting one. It all begins with a digital plan. This plan is known as a CAD file. CAD stands for computer-aided design. You can make this file on your own with special computer programs. You can also find one online that another person has already made. This file gives the machine all the directions it needs to make your part.

After the printer has the file, the actual 3d printing process starts. The printer first warms up a special thermoplastic filament. It gets warm until it is soft like goo. This filament is then pushed into a small, hot metal point called a nozzle. The printer then starts the extrusion step. It pushes the melted plastic out of the nozzle while it moves above the build platform. It draws the first layer of your item. The thermoplastic gets cold very fast and becomes solid. The platform then lowers just a little bit, and the printer begins to draw the next layer. This is how it builds parts.

One of the greatest things about an FDM printer is the very big choice of materials. The printer works by melting a thermoplastic filament. So, almost any thermoplastic that can be turned into a filament can be used. This means there are many different materials are compatible with an FDM 3D printer. The number of filaments are available is really great. This is a good thing because different materials are good for different jobs.

For people just starting out and for easy projects, materials like PLA and PETG are used a lot. They are simple to print with and do not cost much money. But FDM 3D printing is not just for fun projects. For company jobs that need very strong parts, you can use special materials. These include strong plastics like Nylon and polycarbonate. You can even use a filament that has carbon fiber mixed in it to make parts that are very strong but not heavy. You can also use special high-performance polymers like ULTEM. This wide choice of materials makes the FDM printer a very handy tool.

| Material | How Easy to Print | How Strong It Is | How Much It Costs | What It’s Best For |

|---|---|---|---|---|

| PLA | Easy | Medium | Low | Fun projects, models you look at |

| PETG | Easy | Medium-High | Low | Working parts, food-safe containers |

| Nylon | Hard | Very High | Medium | Gears, parts that bend, strong items |

| Polycarbonate | Very Hard | Super High | High | Strong prototypes that resist heat |

| ULTEM | Very Hard | Super High | Very High | Parts for airplanes and cars |

When I need to check an idea fast, I often use FDM technology. Why do I do this? Because the advantages of FDM are easy to see. This is especially true when you think about how fast and cheap it is. This additive manufacturing technology is one of the quickest and least expensive ways to get a part you can hold.

Here are the main good things I have found:

Of course, no way of making things is perfect. It is important to know the advantages and disadvantages before you pick a way to make something. FDM 3D printing is great for a lot of things, but it does have some weak spots. The main disadvantage I find has to do with how the final 3d print looks and feels.

Because the FDM 3D printer makes parts in layers, you can often see small lines on the surface of a part that was printed using fdm. This makes it feel rougher compared to other 3d printing ways. The detail, or resolution compared to other 3d printers like SLA, is not as good. Also, the connection between the layers is weaker than the plastic itself. This quality is called anisotropic. It means the part is not strong in the same way from every direction. For some parts, this can be a big problem. Lastly, getting the dimensional measurements exactly right can be hard, and you often need to do some light post-processing.

It is good to see how FDM compares to other popular ways of printing. Let’s look at FDM next to two other common types: Stereolithography (SLA) and Multi Jet Fusion (MJF). I have used all three of them, and each one is good for certain things. FDM uses material extrusion. This means it pushes out a melted thermoplastic filament. It is great for making a fast, low-cost prototype.

SLA, however, works in a different way. An SLA printer uses a laser to draw on a tub of liquid plastic. This hardens the plastic one layer at a time. This way of printing makes parts with a very smooth surface and tiny details. It looks much better than FDM. MJF is a process for big jobs. A machine puts down a very thin layer of polymer powder. Then, a special liquid is printed on top to help it sinter, or melt together, with heat. This is good for making many strong and tricky parts all at once. FDM is the easiest to get for a quick 3d print. SLA is for parts with great detail. And MJF is for making a lot of parts.

When your printer is done with its job, your work might not be finished. The part that you take off the build plate is often not ready to use yet. The next step is known as post-processing. For an FDM 3d print, this almost always begins with taking off any support material. Supports are extra bits the printer makes to hold up parts of your 3d print that hang over. Sometimes, a special soluble support material is used. This kind of support can just melt away in water.

After you take off the supports, other post-processing methods can be used. These steps make the fdm printed parts look and feel much better. This can mean sanding the surface to get rid of the layer lines. It can also mean painting the printed part. You can also use a special mist to make the surface smooth and shiny. For many jobs, post-processing is required to get a 3d print that looks really good.

A thing people often get wrong is that FDM 3D printing is only good for making a simple prototype. It is a great tool for rapid prototyping, but it can be used for many other things. I have seen FDM used to make all sorts of helpful things. These range from functional prototypes that you can test just like the real item, to end-use parts that go right into products. This technology is a real manufacturing method.

Because of the strong materials you can get, you can make very tough FDM parts. Many factories use an FDM printer to make special tools, jigs, and fixtures. These help them build their products better. A special fixture might cost a lot of money and take weeks to order from a shop. But with FDM, it can be printed overnight for just a little money. In big areas such as automotive, engineers create parts to test right on a car. With materials like carbon fiber nylon, you can make a 3d print that is almost as strong as aluminum.

You might hear people use another name: Fused Filament Fabrication, or FFF. This might make you confused. Are FFF and FDM not the same thing? The easy answer is that they are. They are the very same process. Both names describe the material extrusion way of melting and putting down a filament to make a part. FDM is known as the first name for it.

So, why are there two names? It has to do with business. The name Fused Deposition Modeling and the short name FDM were owned by a company called Stratasys 3D. They invented this technology a long time ago. When other companies, like the ones that make Stratasys 3D printers, began making similar machines, they needed a new name to stay out of trouble. So, the people who use these printers came up with the name Fused Filament Fabrication to talk about the process. So, all FDM is FFF, and all FFF is FDM.

Maybe you have a plan for a 3d print, but you do not have a printer. That is okay! You do not need a machine to use FDM. There are many businesses that offer industrial 3d printing. You can use their big, powerful machines to make your part. The way to do it is very simple and quick.

You just need to send your CAD model file to their website. After you send it, you pick from a list of materials. You also pick how good you want the quality to be. The website’s program will look at your model and right away figure out the cost. In just a few moments, you can get an instant quote for your 3d print. This is a great way to make a very good 3d print without needing to buy and run your own printer. It makes powerful 3d printing technologies easy for everyone to use.

To sum it all up, here are the most important things I have learned about Fused Deposition Modeling over the years.