Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Do you have a fiber laser cutting machine? Do you want to know how to get a great cut every time? The trick is using the right settings. It can be hard to find the right mix of laser power, cutting speed, and the thickness of the metal. This guide is here to help you. We will show you just how to pick the best settings for your machine. If you read this article, you will save time. You will also waste less material. It will help you make clean and fast cuts in your work shop.

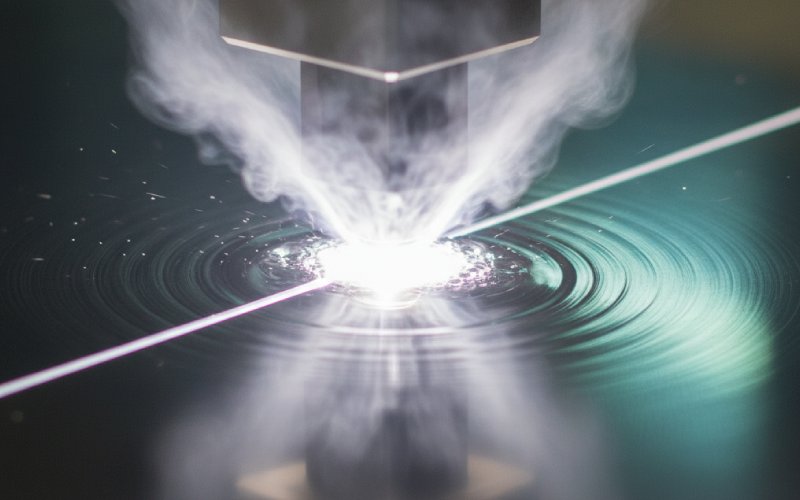

Fiber laser cutting is a way to cut things. It uses a strong, focused beam of light. This light melts, burns, or turns the material into gas. A fiber laser machine makes this strong light. It sends the light through a special cable to a cutting head. The head points the light onto a very small spot on the metal.

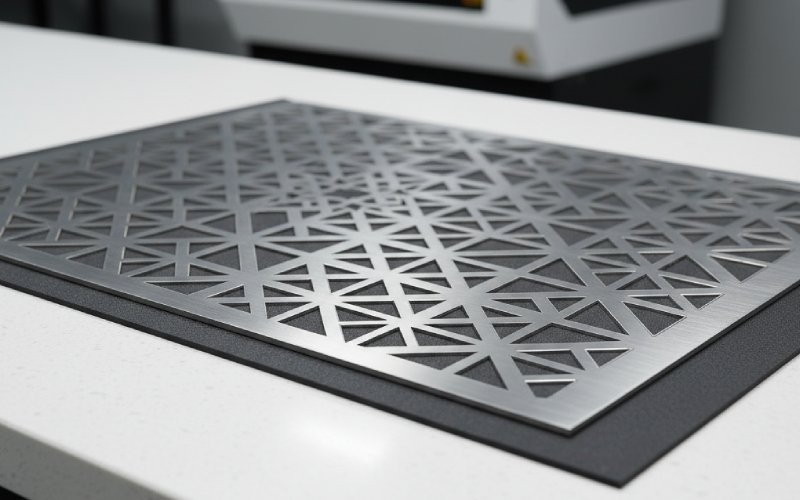

The very strong heat melts the material right away. Then, a stream of gas blows the melted metal away. This leaves a very clean and exact cut. Fiber laser cutting is very fast. This is because the energy is packed into a small area. Think of it like using a magnifying glass to focus sunlight. A fiber laser does the same thing but with much more power. This allows the machine to cut through metal at a high speed. A new laser cutter can work 5 to 50 times faster than old ways of cutting. This makes the whole job very good for any shop that cuts metal parts. The machine can make tricky shapes that look great.

Power is the main thing to think about in laser cutting. The power of a fiber laser is measured in watts (W). A machine with more power can do two things. It can cut through thicker metal. Or, it can cut thinner metal at a much faster speed. Think of it like a car’s engine. A bigger engine can make a car go faster or pull a heavier load. The same is true for a power laser.

Power, speed, and thickness are all connected.

For example, a 6000w laser can cut 10 mm stainless steel much faster than a 3000w laser. The 6000w machine is also able to cut much thicker steel. A 3000w machine cannot cut it at all. Picking the right amount of power is very important for a good cut.

Picking the right power for your laser cutter depends on your jobs. You should think about the material and how thick it is for the jobs you do the most. A small shop cutting thin steel sheets needs a different machine. A large factory cutting thick aluminum plates will need a stronger one.

A 3000w fiber laser cutting machine is a good choice for many jobs. It can work with many kinds of materials and thicknesses. A 3000w laser can easily cut steel up to 20 mm thick and stainless steel up to 10 mm thick. This amount of power gives a good mix of price and what it can do for many shops. Many people choose this one.

If your shop cuts very thick metal, you should look at a laser with more power. You should also get one if you need to make parts in a very fast way. A 6000w fiber laser cutter can cut thick steel over 25 mm and stainless steel over 12 mm. It will also cut thinner materials very, very fast. A 6000w machine costs more money. But it can help your shop get a lot more work done. The right power for your cutter depends on your work.

The kind of material you are cutting has a big effect on speed. Different metals take in the laser’s energy in different ways. Some metals soak up the laser energy well. Others bounce it off. This means the cutting speeds can be very different.

You should always use a cutting chart. A chart helps you find the right starting speed for each different material and thickness.

When a laser cutting machine cuts metal, it uses a stream of “assist gas.” This gas comes out of the nozzle with the laser beam. The gas does two main things. First, it keeps the lens safe from melted metal. Second, it blows the melted material out of the cut. The kind of gas you use will change how the cut looks and how much it costs.

The two gases people use most are compressed air and nitrogen.

| Gas Type | Good Things | Bad Things | Best For |

|---|---|---|---|

| Air | Costs very little (it’s free!) | Can leave a dark, burned-looking edge | Plain steel when the edge does not need to be perfect |

| Nitrogen | Makes a very clean, silver edge | Costs more than air | Stainless steel, aluminum, and any part |

| Stops rust from forming | Needs special high-pressure tanks | that must have a perfect look. |

Using air is a good way to save money when you cut regular steel. The edge of the cut will be dark, but that is okay for many parts. For stainless steel or aluminum, you should use nitrogen almost all the time. Using nitrogen gas gives you a perfect, shiny edge. You will not have to clean it later. This can save you a large amount of time in your shop.

Here is a guide to help you find the right settings. This chart gives you starting speeds for common materials with different power levels. Do not forget, these numbers are just a guide. Your own machine and material might need small changes. You should always make a small test cut first.

Notice: Speeds can be different because of the machine, how pure the gas is, and the quality of the material. Use this chart as a place to start.

| Material | Thickness (mm) | 3000W Power Speed (m/min) | 6000W Power Speed (m/min) | Assist Gas |

|---|---|---|---|---|

| Mild Steel | 1 mm | 25-30 | 50-60 | Air |

| 3 mm | 7-9 | 15-18 | Air | |

| 6 mm | 2-3 | 4-5 | Oxygen | |

| 10 mm | 1-1.5 | 2-2.5 | Oxygen | |

| 16 mm | 0.6-0.8 | 1-1.2 | Oxygen | |

| 20 mm | 0.5-0.6 | 0.8-1 | Oxygen | |

| Stainless Steel | 1 mm | 20-25 | 45-50 | Nitrogen |

| 3 mm | 5-7 | 12-15 | Nitrogen | |

| 6 mm | 1.5-2 | 3-4 | Nitrogen | |

| 8 mm | 0.8-1 | 2-2.5 | Nitrogen | |

| 10 mm | 0.6-0.7 | 1.5-1.8 | Nitrogen | |

| 12 mm | – | 1-1.2 | Nitrogen | |

| Aluminum | 1 mm | 18-22 | 40-45 | Nitrogen |

| 3 mm | 4-6 | 10-12 | Nitrogen | |

| 6 mm | 1-1.5 | 2.5-3.5 | Nitrogen | |

| 8 mm | 0.7-0.9 | 1.8-2.2 | Nitrogen | |

| 10 mm | 0.5-0.6 | 1.2-1.5 | Nitrogen |

You can see from the chart that a 6000w machine is often two times as fast as a 3000w machine. This can make a big difference in how much work your shop gets done.

Yes, you can cut very thick steel if you use a high-power fiber laser. A long time ago, people used other ways to cut thick metal. But today’s fiber laser cutting machines are very strong. A 6000w machine can cut steel that is up to 25 mm thick. Lasers with even more power, like 12,000W or 20,000W machines, can cut steel that is 40 mm, 50 mm, or even up to 100mm thick.

But there is a trade-off. When you cut very thick material, the speed gets very slow. For example, cutting 25 mm steel with a 6000w laser might be at a speed of only 0.6 meters in one minute. It also gets harder to make the edge look good. For many jobs, a laser is still the best pick for thick material because it is very exact. But for easy, straight cuts on very thick steel, other ways might be faster.

Power and the type of material are the biggest things. But other things can change your cutting speed and how good the cut is. To get the best cut, you need to watch your machine.

You must watch all these parts of your laser cutting process to keep it working well.

Finding the perfect settings is an easy thing to do. Use your cutting chart as your guide.

If you follow these steps, you can find the best settings for any job in a quick way. You can get a perfect cut every time.

A fiber laser cutting speed and thickness chart is a very helpful tool for a modern metal shop. It is more than just a list of numbers. It is a guide to make your shop work better. A good chart helps you work faster and in a smarter way.

When you use a chart, you do not have to guess at the setup. This saves a large amount of time. It also saves you money because you do not waste as much material on bad test cuts. Using the right settings from the chart helps make sure you get good parts for your customers. It makes your whole shop work better and earn more money. Every person who uses a laser cutter should have a good chart they can trust next to their machine.