Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

The difference between a fillet and a chamfer might seem like a small detail. But picking the right one is very important. It affects your part’s strength, how much it costs, and how it fits with other parts. This article will explain everything in a simple way. We will look at what a fillet and a chamfer are. We will also talk about why you need them. And I will show you how to pick the right one for your work. When you finish reading, you will be able to make better design choices for your next CNC machining project.

Let’s begin with the simple facts. The idea of a fillet and chamfer is easy to understand once you see it. Think about the sharp corners on a block of metal. If you run your hand on that sharp edge, it could be dangerous. A fillet and a chamfer are both ways to fix that sharp edge. But they do it in different ways.

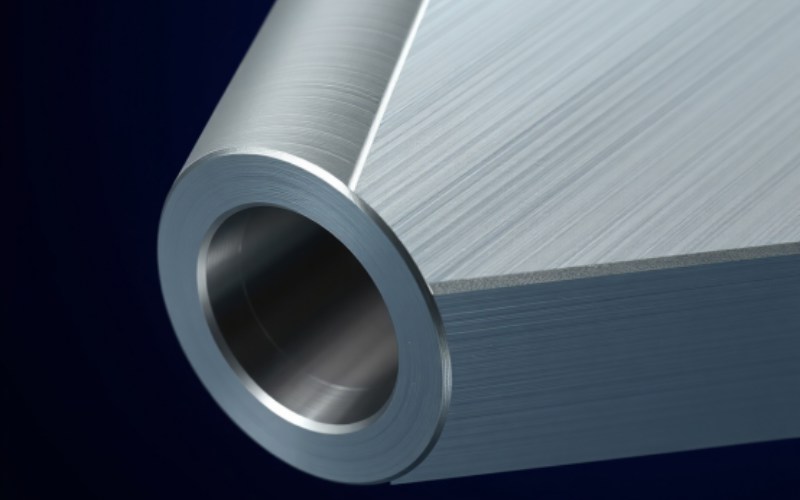

A fillet is a corner or edge that is rounded. Picture the inside corner of a box. If you make that corner smooth with a curve, that is a concave fillet. If you round off an outside sharp edge, that is a convex fillet. The important word to remember is “rounded.” A fillet always has a radius. So, you can say a fillet is a rounded edge. A design that uses fillet engineering will always tell you the size of this radius.

A chamfer is different. It is a straight edge that is cut on an angle. Instead of rounding the corner, you cut it off at an angle. This makes a flat surface, which is also called a bevel. This means a chamfer is an edge that has a slope. You will often see a chamfer described by an angle and a length, like a 45-degree chamfer. So, while a chamfer is flat, a fillet is curved. That is the biggest difference between a fillet and a chamfer.

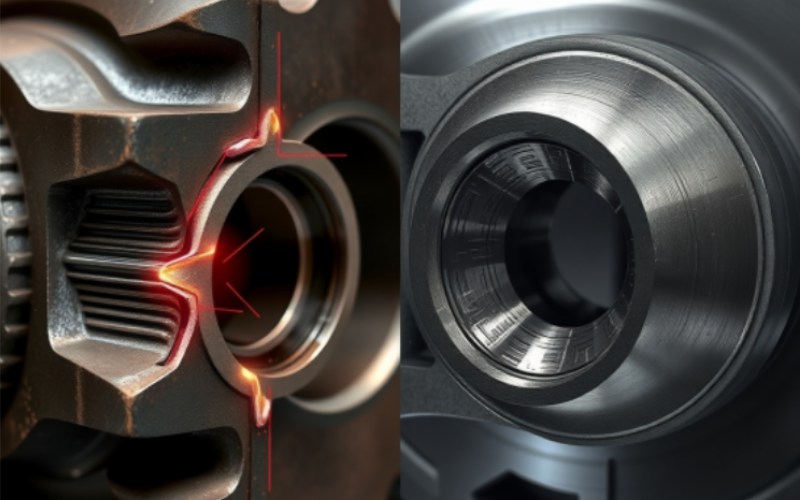

Yes! The way they look is the easiest way to see the difference. If you look at the corner of a part, a fillet looks like a corner that is smooth and rounded. It has a soft curve. An example is the smooth rounded edge on your phone. This feature helps stress flow smoothly through the part.

A chamfer looks like a clean, flat cut made at an angle. It is a beveled edge. A common example I see all the time is on the tip of a bolt or at the top of a screw hole. That little slope helps the bolt or screw go in easier. This sloped edge is a chamfer. When you look at a part, if the edge is a straight line that is cut at an angle, it is a chamfer. If it is a smooth rounded corner, it’s a fillet. The difference between a fillet and a chamfer is easy to see when you know what to look for. A chamfer is an angled cut, and that is a simple way to think about it.

In my work, we do not add these things to a part just for looks. In mechanical engineering, there is a reason for every choice. We use a fillet and chamfer for a few very important reasons. The most common reason is for safety. A sharp edge on a machined part can cut a person who is holding it. Adding a small fillet or chamfer makes the part much safer to handle.

Besides safety, these features make the part work better and last longer. A chamfer edge helps to guide two parts so they fit together. For instance, putting a chamfer on the end of a pin makes it much easier to put into a hole. This is very helpful for mating parts that need to be put together. This action is called pin insertion. A chamfer is the better choice for this.

Fillets are amazing when you need to make a part strong. A sharp corner is a weak spot on a part. Stress can build up in sharp inside corners. This can cause cracks and make the part break. We call this stress concentration. A fillet helps spread that stress out over a bigger area. This makes the part much stronger. I will explain more about how a fillet allows for this in the next part. We use a fillet and a chamfer to make parts that are better, safer, and stronger.

This is a very interesting part of the engineering behind it. Think about water flowing in a pipe that has a sharp 90-degree turn. The water would crash into the corner, making the water flow in a messy way. Now, picture that corner as a smooth, gentle curve. The water would flow around it smoothly. The way stress flows in a metal part is a lot like this. This is a main idea in fillet engineering.

A sharp inside corner creates a spot of high-stress concentration. When a load-bearing part is under pressure, all of that force is pointed at that one small spot. This can cause a crack to start, which can cause deformation or make the part break completely. When you use a fillet, you make a radius. This makes the corner smooth. This helps to reduce stress by giving the stress a wider path to move along. The stress can flow more evenly. This makes the part’s load-bearing capacity much bigger.

The bigger the radius of the fillet, the better it works to lower stress concentration. So when a part must be very strong and handle a lot of force, I always look for designs that use large fillets. They are very important to reduce the risk of the part breaking. A radius fillet is very important for making a strong machine part. We often use fillets for the specific reason to help to reduce this stress.

Fillets are great for making parts strong. But sometimes a chamfer is the better and more useful choice. One of the biggest reasons to use chamfers is for putting mating parts together. As I said before, a chamfer edge works like a little ramp. It helps guide a pin into a hole or helps a bolt find the threads. This makes putting things together faster and stops the parts from getting damaged. For instance, a chamfer in a hole can help drive screw threads in with ease, stopping them from getting stuck.

A chamfer can also be a better choice when you only need to break the sharp corners. You might do this for safety. Or, you might do it to stop a weak edge from breaking off. A small chamfer is perfect for this job. It is also often faster and cheaper for the machine to make than a fillet. It gives a clean look and is not as complex as making a perfect radius.

Also, a fillet is not a good idea for outside edges. This is true if they need to fit tightly against another flat surface. The rounded fillet edges would leave a small open space. A chamfer makes a flat, angled surface that can still sit flat against another part. So, when working with mating parts or just needing to break an edge, I often think a chamfer is the smarter choice for the design and machining operation. A chamfer is a great pick for a fast machine job.

When you are running a CNC machine, the choice of a fillet vs chamfer can change your project’s time and cost. Here is an easy table I use to show the differences between fillet and chamfer to my team.

| Feature | Fillet | Chamfer |

|---|---|---|

| Shape | Rounded, curved edge (concave or convex) | Straight, angled, or sloped edge (bevel) |

| Primary Use | Reduce stress concentration, increase strength | Aid assembly, de-burr, break a sharp edge |

| Measurement | Defined by a radius (e.g., R3mm) | Defined by an angle and distance (e.g., 45° x 1mm) |

| Machining | Often requires a special ball-nosed cutting tool | Can often be made with a standard cutting tool |

| Cost | Can be more expensive due to tool needs and time | Generally cheaper and faster to machine |

The most important thing to learn here is that chamfers are more forgiving to make. You can often use a single tool to create chamfers of different sizes. Fillets, especially if you need a certain radius size, might need a special tool. This makes the setup time longer and increases the manufacturing costs. This is a big deal in any machine shop. Understanding the difference is important for managing costs.

The way we make them on the CNC machine is very different. To create a chamfer, I can often use a normal end mill or a special chamfer mill. I can program the machine to follow the edge of the part at a certain angle and depth. This is a fairly easy and fast job. It is easy to make different chamfer sizes with the same tool by just changing the path of the machine.

Making a fillet with a machine is a little more difficult. To get that perfect rounded edge, you need a special cutting tool. It needs a rounded tip. A ball-nose endmill is one example. The tool must have the exact radius that the design asks for. The machine has to follow a more complicated path to create the smooth curve. This can make the machining time longer. Compared to chamfer, this process needs more attention.

For both a fillet and chamfer, being exact is very important. The machine must be set up correctly to get the right sizes. But I usually find that a chamfer doesn’t need as many special tools as a fillet does. This makes it a faster job to do on the machine.

So, how do you decide which one to use? Here is what I think about when I look at a part design. To make the right choice, you need to ask the right questions about what the part will do. When choosing between a fillet and a chamfer, I think about the job of the part first.

Yes, they are! The world of 3D printing has its own rules. But the basic ideas of fillets and chamfers are still used. Actually, they can be even more important in 3D printing. A sharp 90-degree corner in a 3D printing design can create a weak spot. The layers can pull apart or bend there.

Adding a fillet helps make a stronger connection between the layers as they are built. It helps to reduce stress concentration, just like it does in a machined part. It also is a big help with overhangs. Fillet allows for a slower change in shape. This can be easier for the 3D printing process to create than a sharp overhang.

A chamfer is also very helpful in 3D printing. A 45-degree chamfer on the bottom edge of a part can help stop the part from bending. It can also help it stick to the printing surface better. This is because a sharp corner can lift up as the part prints. The sloped or angled edges of a chamfer make a better base. So, it does not matter if you are using machines or 3d printers. Understanding the fillet and chamfer is very important. Chamfers are not recommended for parts with high stress, even in 3D printing.

When all is said and done, both the fillet and chamfer are very important tools for a designer and a machinist. They are not fighting each other. They are answers for different kinds of problems. A fillet is your best choice for strength and for making things last a long time. It fights against stress concentration in important spots. A chamfer is your top choice for easy assembly, safety, and for making parts without spending too much money.

I have worked on many projects. Making the right choice made a very big difference. Knowing when to use a fillet and when a chamfer is the better choice will help you become a better designer. It will also help you make parts that are strong, work well, and are easy to produce. It is a basic, but very important, part of good mechanical engineering. The next time you see a drawing, you will know exactly what those curves and angles mean for the machine and for the part you are making.