Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

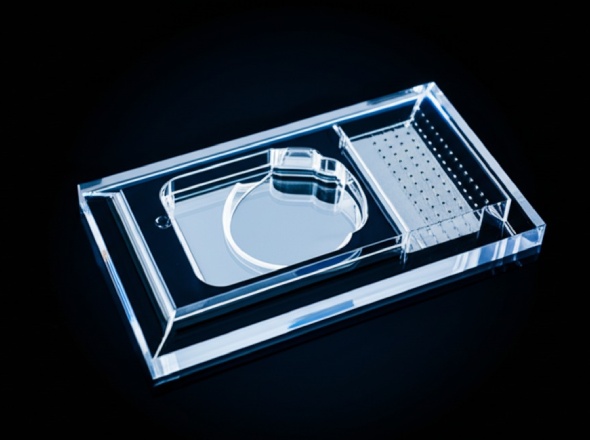

Are you looking for glass parts made with top-level precision? At Istar Machining, we turn glass into exactly what you need. Our glass CNC machining services help make parts for many industries that need special glass components.

Glass is a tricky material to work with. But with our special tools and know-how, we can cut, shape, and polish glass to meet your exact needs. Whether you need parts for medical devices, fancy displays, or high-tech equipment, we’ve got you covered.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Our precision CNC machining equipment allows us to create glass components with amazing accuracy. Here’s what we can achieve:

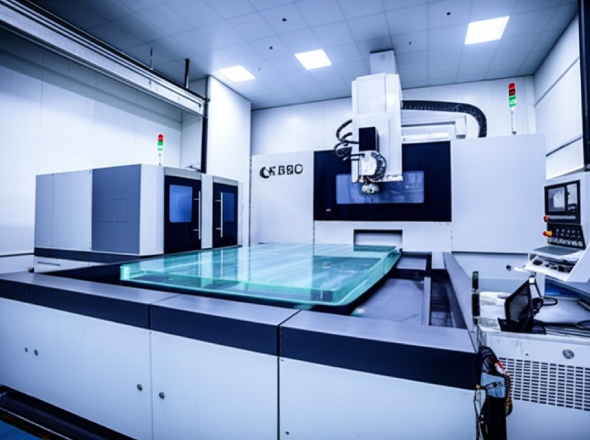

We use special 5-axis CNC machines that can reach all sides of your part in one setup. This means better accuracy and faster production times.

We can machine many types of glass to fit your needs:

Glass Type | Best Uses | Special Features |

Borofloat® 33 | Lab equipment, Optics | Handles heat changes well |

Zerodur® | Satellite parts, Precision optics | Extremely stable |

Fused Silica | Laser parts, UV applications | Great for light work |

Soda Lime | Common glass needs, Displays | Cost-effective option |

Quartz | High-heat applications | Withstands extreme heat |

Ultra-Thin Glass | Mobile devices, Flexible displays | For tiny components |

Not sure which glass is right for your project? Our team can help you pick the best material based on how it will be used and what properties you need.

Glass CNC machined parts are used in many industries. Here are some ways our customers use our services:

Some glass machining jobs are extra challenging. At Istar Machining, we specialize in:

Our 5 axis machining centers allow us to create shapes that would be impossible with simpler equipment.

Our glass CNC machining can create many special features:

We can combine these features in one part to create exactly what you need.

After the main machining is done, we offer these extra services:

These treatments can make your glass parts work better and last longer.

At Istar Machining, quality is our top priority. We check every glass part using:

We follow strict quality standards including:

Every part comes with quality reports so you know exactly what you’re getting.

When you choose our CNC machining service, you get:

We've been working with glass for many years

Our 5-axis machines can create complex shapes

We understand how different types of glass behave

Get prototypes in 3-5 days, production in 2-4 weeks

Competitive pricing without sacrificing quality

From design help to finishing treatments

When you work with Istar Machining for glass CNC machining, here’s what happens:

We look at your designs and suggest changes if needed to make them easier to machine

Our experts create the computer code that guides our machines

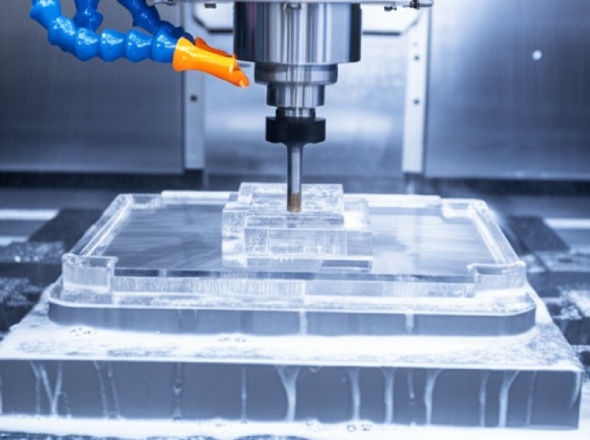

Using diamond tools, we carefully shape your glass

Every part is checked to make sure it meets all requirements

We can add special treatments like edge polishing or chemical strengthening

Ready to bring your glass component ideas to life? Here’s how to get started:

Contact us today to discuss your glass CNC machining needs:

At Istar Machining, we combine cutting-edge technology with years of experience to deliver glass parts that exceed your expectations. From prototypes to production runs, we’re your partner for precision glass components.

Glass CNC machining uses computer-controlled machines to shape glass with great precision. Unlike hand cutting, CNC machines follow exact digital instructions to create perfect glass parts every time.

Our machines use diamond tools that can work with even the hardest glass types. This means we can make parts that meet very strict rules for size and shape.

Yes, we have special techniques for working with tempered and laminated glass without causing delamination or edge chipping.

We accept STEP, IGES, DWG, SolidWorks, and other major CAD formats. Our engineers can also work from drawings if needed.

Most prototype glass parts can be ready in 3-5 business days. More complex projects may take longer.

We use special fixtures and machining techniques to support the glass and prevent breakage during the process.

Yes, we can work with specialty glass to meet specific refractive index, transmission, or other optical requirements.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or