Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

The glass transition temperature (Tg) might sound hard, but it’s the secret to knowing why a hard, breakable plastic doesn’t just turn into a liquid and why a rubber band is stretchy at room temperature. This article is for you if you have ever asked how the same basic materials can be used for so many different things, from stiff glasses to soft phone cases. I’ll explain the idea of glass transitions using easy words, talking about the science without the hard-to-understand terms. We will look at what the glass transition temperature of polymers is, what things change it, and why it’s a big deal for the products we use each day. When you finish reading this, you will have a good understanding of this key part of polymer science and a new respect for the smart work that goes into making the materials we use.

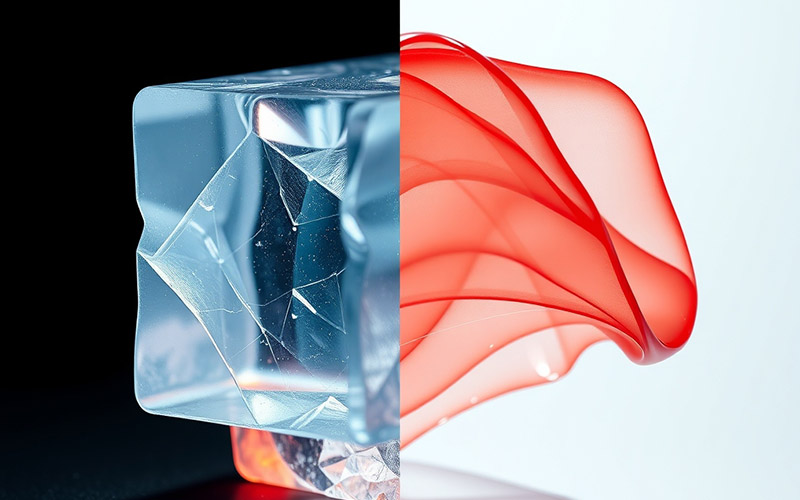

Think about a block of a regular polymer. When it’s very cold, it’s hard and easy to break, like glass. If you were to hit it, it might break into pieces. We call this the glassy state. Now, if you begin to heat this polymer, something neat happens. It does not just melt into a liquid all at once. Instead, it goes through a slow change. It gets softer, more flexible, and rubbery. This change happens over a certain temperature range. The middle of this range is what we call the glass transition temperature, or Tg.

You should know this isn’t like real melting, such as when ice becomes water. A polymer is built from long, mixed-up chains of tiny parts. In the glassy state, these polymer chains are basically stuck. They can shake a little, but they don’t have enough energy to get around. As you heat the polymer and it gets to its Tg, the chains get enough heat energy to begin to slip past each other. This new ability to move is what makes the polymer feel rubbery. So, the glass transition is a change in how the polymer chains can move, not a change from a solid to a liquid.

Think of a plate of spaghetti that has been cooked. When it is cold, the pieces are stuck together and don’t move much. If you heat it up, the pieces can move around each other more easily. This is a simple picture of what happens to the polymer chains during the glass transition. The glass transition temperature is a basic feature of amorphous polymers – those with a messy, mixed-up molecular structure. For semi-crystalline polymers, which have both neat (crystalline) and messy (amorphous) areas, the glass transition only occurs in the messy parts.

Learning about the glass transition temperature of polymers is not just for schoolwork; it is very useful in real life. The Tg of a polymer decides how it will act at a certain temperature and, because of that, what it can be used for. For example, a polymer used to make a car tire has to be flexible and stretchy in many different temperatures. This means its Tg must be much lower than the temperatures it will be in on the road. Stretchy materials like polyisoprene are used above their Tg, which is why they are soft and flexible.

On the other hand, a polymer used for a hard part that gives shape, like a computer case or a water bottle, needs to be stiff and strong at room temperature. These uses need polymers with a high Tg, much higher than room temperature. Hard plastics like polystyrene (PS) and poly(methyl methacrylate) (PMMA) are used when they are in their glassy state, below their glass transition temperatures.

The glass transition temperature is also very important for how polymers are made into products. To give a polymer a shape, like in a mold, it has to be heated above its Tg to a point where it gets soft and can flow. Knowing the Tg lets people who make things figure out the right temperatures for making them. This helps make sure the thing you make has the qualities you want. In short, the glass transition temperature is a key piece of information that helps experts pick the right polymer for a certain job and make it the right way.

The chemical structure of a polymer is the main thing that decides its glass transition temperature. Picture the polymer chains as long ropes. The easier it is for these ropes to move and slip by one another, the lower the Tg. On the other hand, if the ropes are stiff and have things on them that get in the way, the Tg will be higher. This “stiffness” of the polymer chain is often called chain flexibility.

A few parts of the chemical structure change the chain flexibility:

Another key idea for understanding glass transitions is free volume. Picture a jar full of marbles. The marbles are like the polymer chains. The empty space between the marbles is the free volume. This free volume gives the room needed for the polymer chains to move and slip by one another. The more free volume a polymer has, the more easily its chains can move, and so, the lower its glass transition temperature.

When you cool a polymer from its rubbery state, the chains move less and pack closer together. This makes the free volume get smaller. At the glass transition temperature, the free volume gets to a very low point where there is not enough room for the big parts of the chains to move. The polymer chains get “stuck” in one spot, and the material turns into a hard, amorphous solid. This is what the glassy state is all about.

Many things can change the amount of free volume in a polymer. For example, polymers with long, straight chains often have more chain ends. These chain ends make more free volume. As the molecular weight of the polymer goes up, the number of chain ends goes down. This means there is less free volume and a higher Tg. The idea of free volume gives us an easy but good way to think about how the tiny structure of a polymer changes its bigger qualities, especially its glass transition.

Besides the basic chemical structure and free volume, a few other things can change the glass transition temperature of a polymer. These things are often used to change the qualities of a polymer for a certain use.

Here is a table that shows some of these key things:

| Factor | Effect on Tg | Explanation |

|---|---|---|

| Molecular Weight | Goes up with higher molecular weight | Higher molecular weight means longer polymer chains and fewer chain ends. This lowers the free volume and makes the chains tangle more, making it harder for them to move. |

| Cross-linking | Goes up | Cross-links are chemical bonds that join different polymer chains. These links are like steps on a ladder, greatly stopping the movement of the chains and making the Tg go up. |

| Plasticizers | Goes down | Plasticizers are tiny bits added to a polymer. They go between the polymer chains, making more free volume and making it easier for the chains to move. This lowers the Tg and makes the polymer more flexible. |

| Crystallinity | Goes up | In semi-crystalline polymers, the crystalline parts are very neat and stiff. These parts act like physical connections, stopping the movement of the messy parts and making the total Tg go up. |

| Heating and Cooling Rates | Can change the measured Tg | The glass transition depends on time and speed. A faster heating rate can make the measured Tg seem a little higher. |

Knowing about these factors affecting the glass transition temperature lets scientists change the properties of polymers to fit the needs of many different uses, from soft and stretchy to hard and tough.

Since the glass transition is not a clear, sudden event like melting, but a slow change over a range of temperatures, we need special ways to measure it. A few testing methods can be used to find the Tg of a polymer. Each method looks for a certain change in the material’s qualities as it goes through the glass transition.

The most common ways are:

Which method to use depends on the polymer being tested and what you need to know. It is also good to know that the measured Tg value can be a little different based on the method used and how the test is set up, like the heating rate.

This is something people often get mixed up, but the glass transition temperature (Tg) and the melting temperature (Tm) are very different things. The main difference is in the kind of polymer and the way the change happens.

To say it simply, at the Tg, the messy polymer chains begin to wiggle and move. At the Tm, the neat crystal shapes completely fall apart and melt. Knowing this difference is very important for understanding how polymers act in general.

Polymers with high glass transition temperatures are needed for uses that need them to be stiff, strong, and able to handle heat. These materials are used in their glassy state at room temperature, which means their Tg is much higher than 25°C (77°F). The high Tg is caused by their stiff chemical structures, which stop the movement of the polymer chains.

Here are some polymers with high Tg:

| Polymer | Abbreviation | Typical Tg (°C) | Common Uses |

|---|---|---|---|

| Polystyrene | PS | ~100 | Throwaway cups, insulation, CD cases |

| Poly(methyl methacrylate) | PMMA | ~105 | Plexiglass, signs, lenses |

| Polycarbonate | PC | ~150 | Eyeglass lenses, CDs, water bottles |

| Poly(phenyl sulfone) | PPSU | ~220 | Medical tools, airplane parts |

| Polyether ether ketone | PEEK | ~143 | Parts for planes and space, medical implants |

| Polyimides | PI | >250 | Films for high heat, coatings, glues |

These strong polymers are very important in fields like space travel, cars, electronics, and medicine, where materials often have to deal with high temperatures and a lot of physical force. Making new polymers with even higher glass transition temperatures is something scientists are working hard on.

The glass transition is not only about how heat and energy work; it is also very affected by kinetics, which is the study of how fast things happen. The making of a glassy state is something that depends on time. Whether a polymer becomes a glass or a crystalline solid when it cools down from being a liquid depends on how fast it is cooled.

If a polymer liquid is cooled very slowly, the polymer chains have time to line up into a neat, crystalline shape. This process of making crystals has two steps: starting tiny crystals and then making them bigger. But if the liquid is cooled very fast (this is called quenching), the chains do not have time to line up into crystals. Their movement gets slower and slower until they are basically “stuck” in a messy, amorphous solid state – a glass.

The kinetics of the glass transition also show why the measured Tg can change with the heating rate. With a faster heating rate, the polymer chains have less time to react to the hotter temperature, so the change seems to happen at a temperature that is a little higher. This time-based quality is a key part of the glass transition and makes it different from a real heat-based change like melting. The way that heat energy and speed work together is what makes looking at glass transitions so interesting and not so simple.

To finish our close look at the glass transition temperature of polymers, here are the most important ideas to keep in mind: