Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Do you want to make a design on a piece of metal that will last forever? Maybe you want to put your own touch on tools, make special jewelry, or add logos to metal parts. If so, this guide will help. We will show you all the important things about how to laser engrave metal. You will find out what it is, what tools you need, and how to do a good job. This article explains a tricky subject in a simple way. It is perfect even if you are just starting out with laser engraving.

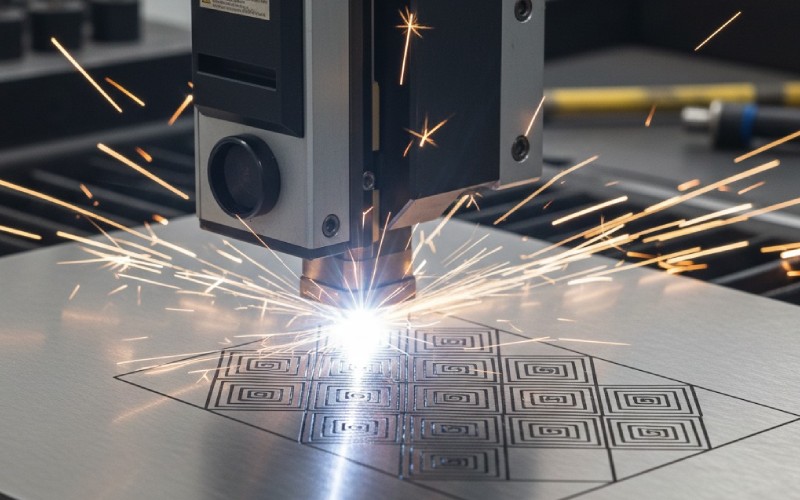

Laser engraving is a way of using a powerful light beam to make a mark on something. You can think of it as a very strong and exact pen that uses light instead of ink. When you want to engrave metal, you use a special machine called a laser engraver. This machine points a sharp laser beam onto the metal surface. The power from this laser beam is so strong that it makes the metal hot in a flash. This heat can vaporize the material. This means it turns the solid metal into a gas.

The laser engraver moves this laser beam from side to side to engrave a design. As the laser removes material from the top of the workpiece, it makes a small cut. These cuts form the letters, numbers, or pictures you want to engrave. You can engrave designs with a lot of small details because the laser beam is very small and exact. This process lets you personalize many things made of metal. The power to engrave with such detail is why a lot of people choose to laser engrave. It’s a great way to engrave a mark that lasts.

The way you engrave metal is very clean and quick. The laser engraver is run by a computer, so each engrave comes out just right. You just tell the computer what to engrave, and the engraving machine does the rest of the work. The machine will engrave exactly what you have in your design. The way the laser interacts with the metal to engrave it is an important part of laser technology. You can engrave almost any design you can imagine on metal surfaces.

There are some different ways a laser engraver can make a mark on metal. These are known as the types of laser engraving. Each engraving technique makes things look and feel different. The three top ways to know are deep engraving, laser etching, and laser marking. All of these use a laser engraver to engrave a design. But they do it in ways that are a little bit different. To engrave well, you have to pick the best way for your job.

Let’s look at how they are different. To engrave deeply means you remove material to make a cut you can see and feel. Laser etching is not the same. When you laser etch, the laser beam melts the top of the metal. This makes it swell up and create a mark that is raised up. Laser marking is a process that uses less power. The laser changes the color of the metal’s surface without taking away much of the surface at all. This is great when you need to engrave a barcode or logo with a high contrast, or a very clear difference in color. Each method is a way to laser engrave, but what you get at the end is special. It’s key to engrave using the method that is the best fit for what you are making.

| Engraving Type | How it Works | Best For |

|---|---|---|

| Deep Engrave | The laser beam will vaporize and remove material to make a deep mark. | Parts that need marks that last, like serial numbers. A good way to engrave tools. |

| Laser Etching | A strong laser beam melts the surface, making a raised, bumpy texture. | Making textured marks on metal surfaces that you can feel. A special way to engrave. |

| Laser Marking | A low-power laser warms the metal to change its color. This makes a smooth, lasting mark. | Logos and barcodes where a smooth surface is needed. You can laser engrave with great detail. |

When you want to engrave metal, the biggest decision you will make is the type of laser you use. There are two main types used in an engraving machine: the fiber laser and the CO2 laser. For metal engraving, the fiber laser is usually the top pick. A fiber laser makes a laser beam with a special kind of light. Metal surfaces soak up this light easily. This makes it work really well to engrave metal.

A fiber laser can engrave on almost all kinds of metal. This includes steel, aluminum, brass, and titanium. The focused laser beam from a fiber laser is very small. This lets it engrave designs with tons of detail and intricate designs. Being so exact makes them perfect for engraving small words or tricky logos. If your main goal is to engrave metal, a fiber laser will give you clean, sharp, and lasting results. This type of laser is the tool that pros use for metal engraving because it is strong and you can count on it. To engrave with a fiber laser is to engrave knowing you’ll get a good result. A fiber laser is the right laser to engrave metal.

A CO2 laser, on the other hand, is great for engraving other materials like acrylic, glass, and leather. A CO2 laser’s light is not taken in well by plain metal. Most of the light will just bounce off the surface. You can use a CO2 laser to engrave metal with a coating or anodized aluminum. But for plain metal engraving, the fiber laser is much better. Using a fiber laser to engrave metal is the best way to do it for any serious engraving projects. This is why the fiber laser is so well-liked for metal engraving.

Picking the right laser engraving machine is very important for doing a good job. There are many choices, from small desktop laser engravers for a small business to big ones used in factories. The right engraving machine for you depends on what you want to engrave. First, think about the materials. If you will only engrave metal, a fiber laser machine is what you should get. If you want to engrave many kinds of materials like wood or acrylic and also metal, you might need a machine with both fiber and CO2 laser types, or two different machines.

Next, think about the size of the things you want to engrave. The size of the work area on the engraving machine shows you the biggest thing you can put inside. For little things like jewelry, a small laser engraver is all you need. For bigger things like sheet metal parts, you will need a larger engraving machine. Also, think about the power of the laser. More laser power means you can engrave with more speed and depth. For most home or small business engraving tasks, a 20 to 50-watt fiber laser is a good start. A stronger laser machine is better for factory work.

Last, check the software and special abilities. A good laser engraver should have design software that is simple to use. This lets you make or bring in your designs. Look for an engraving machine with a good warranty and help from the company. Some machines have advanced features, like a camera to help you line things up or a turning tool to engrave round items. Finding the right laser engraver means you can laser engrave your ideas onto metal without trouble. These types of laser engraving machines give you a lot of options. The price of a laser engraver can vary widely, so it’s a good idea to know your budget.

The laser engraving process is easier than you think once you know the steps. It is a wonderful way to personalize metal things. Here is a simple list of how you can laser engrave a design from start to finish.

This is a question a lot of people ask. The quick answer is no, a regular CO2 laser can’t engrave plain metal by itself. A CO2 laser makes a laser light beam that most metal surfaces bounce off. The laser energy just bounces away instead of soaking in to engrave the metal. It is like trying to point a flashlight at a mirror. Most of the light just reflects away. So, if you try to use a laser like a CO2 laser to engrave steel or aluminum, it will not do a good job.

But, there are ways to get around this. You can use a laser like a CO2 laser to engrave metal if the metal has a layer on top. For instance, anodized aluminum has a colored layer. A CO2 laser engraver can easily take off this layer to show the plain metal underneath. This makes a nice mark with high contrast. You can also use a special marking spray on the metal. You spray a thin coat on the workpiece, let it dry, and then laser engrave on top of it. The laser’s heat melts the spray onto the metal, making a lasting black mark. After you engrave, you wash away the leftover spray.

So, even though a CO2 laser is not the top tool for engraving metal, you can make it work with a few more steps. But for real, direct metal engraving where you want to remove material from the surface, a fiber laser is the right tool for the job. A fiber laser is made just for materials that are suited for engraving, like metal. To correctly engrave metal, you should pick the right tool. This is why a fiber laser is so important for metal engraving.

Laser marking is a special way of engraving that is one type of how you can laser engrave. When people talk about laser marking, they usually mean making a permanent mark on a surface without taking off much of the surface. People often use laser marking to make marks that are very easy to see because of high contrast. Instead of cutting a deep line, laser marking changes the top of the metal. This is a great way to engrave serial numbers or logos.

A common type of laser marking is called laser annealing. In this method, a low-power laser beam warms the metal surface. This heat causes a change in the metal called oxidation on the top layer of the metal. This makes a dark, clean, and very long-lasting mark. The best thing is that the surface stays smooth. This is a big deal for doctor’s tools or other parts that must be kept very clean. Laser marking does not make any cuts where germs can hide.

So, the biggest difference between a deep engrave and laser marking is the depth. A deep laser engrave cuts into the workpiece. Laser marking just changes how the surface looks. Both are done with a laser engraver, and both are ways to laser engrave a design. But laser marking is a more gentle process. It’s a great way to personalize metal items when you need them to stay smooth. It is a special kind of laser engraving technology.

Laser etching and a deep engrave are two methods that both use a laser beam to remove material. But they give you different looks. Laser etching is a quicker way that uses a lot of heat to melt the top of the metal. As the melted metal gets cool, it gets bigger and makes a bumpy mark that sticks out a little. This makes a good contrast between the engraved spot and the rest of the surface. You can often feel the etched spot with your finger. Laser etching is a fast way to engrave a mark, but it does not go very deep.

A deep laser engrave, on the other hand, is made to cut deeper into the metal. The laser engraver uses more power or goes at a slower speed to vaporize the metal, one layer at a time. This makes a real dip in the workpiece. The engraving depths can be set with great care. A deep engrave lasts a lot longer than laser etching. It will not fade away easily, even if it is used in tough places. This is why deep engraving is used for things like marking factory parts or guns.

So, if you need a quick mark that is easy to see, laser etching is a great pick. It is a fast way to laser engrave. If you need a mark that will last forever and can handle a lot of rough use, a deep engrave is the better choice. Both are great ways to personalize and label metal parts using a laser machine. The choice to engrave with one way over the other comes down to what your engraving projects need. The way the laser removes material decides the final look.

While we are talking about how to laser engrave, it is helpful to know about laser cutting. The same kind of laser technology that is used to engrave can also be used for laser cutting. But, laser cutting needs a laser machine with a lot more power. To engrave, you only need to take off a little bit of material from the top. To cut through sheet metal, you need to vaporize the material from the top to the bottom.

A fiber laser is the best tool for laser cutting metal, just like it is for metal engraving. A laser cutter for metal will usually have a laser with 1,000 watts of power or even more. This is a lot more than the 20-50 watts used for most engraving tasks. The laser cutter points its strong beam at a tiny spot on the sheet metal. It melts and turns the metal into gas. A strong puff of gas (like oxygen or nitrogen) pushes the melted metal out of the way, which makes a clean cut.

People know laser cutting is very exact and fast. You can cut out very detailed designs and tricky shapes from metal sheets with very good accuracy. It is used a lot in making things, like creating metal parts for cars, gadgets, and many other products. So, while a desktop laser engraver is great to engrave designs, you need a special factory laser cutter for laser cutting sheet metal. Both methods show the amazing power of a focused laser beam.

To get your metal engrave just right, you need to manage the settings on your laser engraver. The three most important settings are power, speed, and frequency. When you get these right, the laser will engrave to make a clean and sharp mark. You can think of them like the three legs of a stool. If one is not right, the stool will fall over.

Another setting to think about is the focus, or spot size. A smaller spot size focuses the laser’s power. This is great for detailed designs. To get the best results, you might need to do a few practice runs on a spare piece of the same metal. This will help you find the best mix of settings for your specific engraving machine and material. Once you are good at using these settings, you can engrave almost anything on metal.