Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

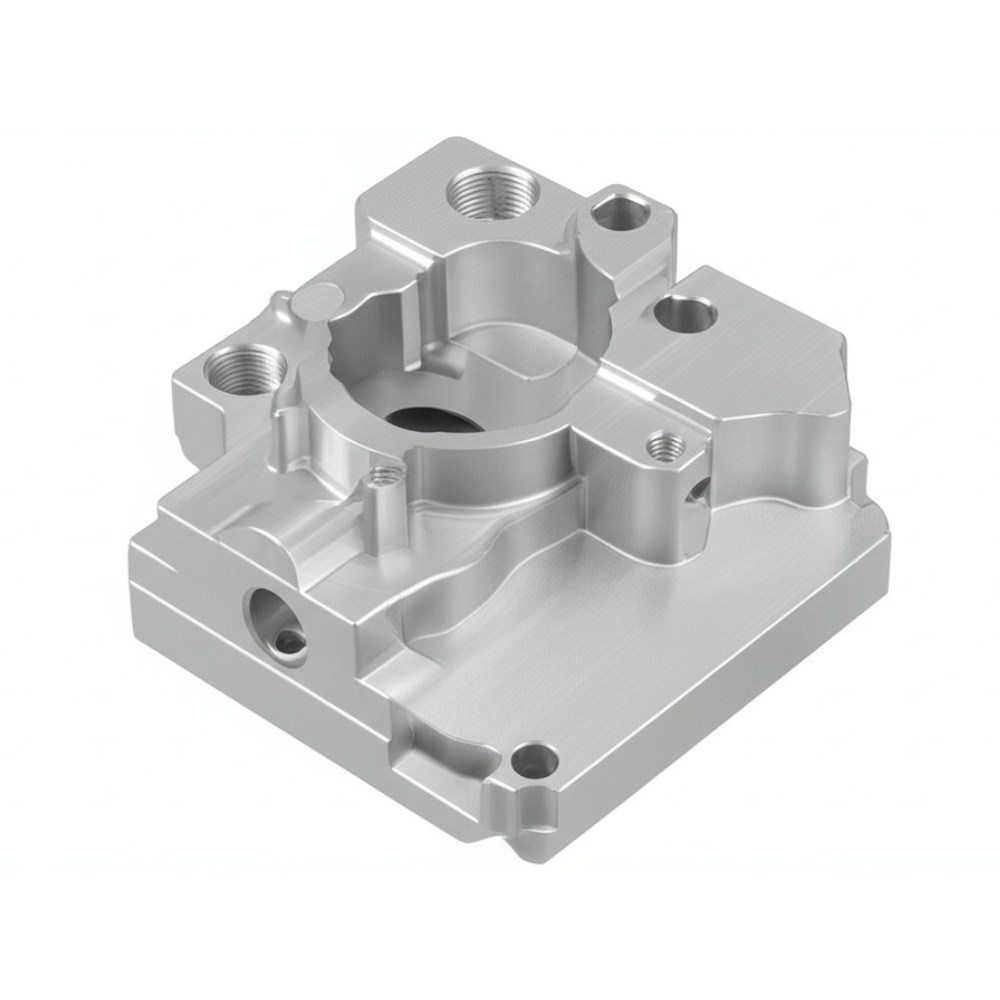

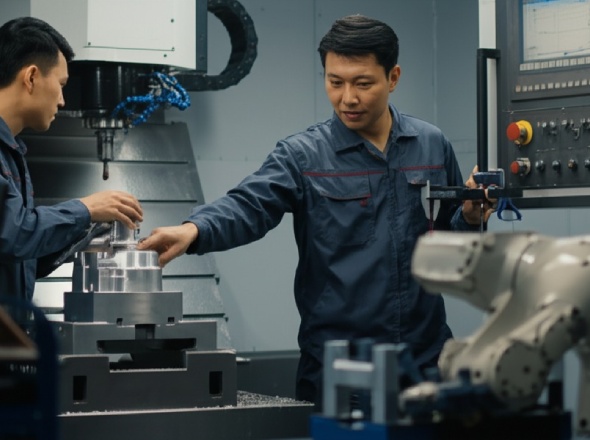

Are you looking for top-quality CNC machining for your industrial projects? Istar Machining offers complete manufacturing solutions that help your business create perfect parts every time. Our team uses cutting-edge technology and follows strict quality standards to make sure your industrial components meet exact specifications.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

At Istar Machining, we provide a full range of CNC machining services that help industrial companies turn designs into real products. Whether you need one prototype or thousands of parts, we can help!

What We Offer | What It Means For You |

Tight Tolerances (±0.005 mm to ±0.05 mm) | Your parts fit together perfectly every time |

Fast Lead Times (3-6 days for prototypes) | Get your projects moving quickly |

Flexible Volume (1 to 100,000+ units) | Order exactly what you need – no minimum requirements |

Advanced Machinery (HAAS UMC-750, DMG Mori 5-axis) | Complex shapes and designs are no problem |

Important Certifications (ISO 9001, AS9100, IATF 16949) | Meet industry standards for quality and safety |

Surface Finishing (Anodizing, Bead Blasting, Powder Coating) | Parts that look great and last longer |

Data Protection (NDA-backed Confidentiality) | Your designs stay private and secure |

Different materials are better for different jobs. Our advanced CNC machining capabilities allow us to work with a wide range of materials to meet your specific project needs. Here’s a look at some of the most common materials we machine and what works best:

Metals

(Common Grades: 6061, 7075, 5052, 2024, MIC-6)

Description: Aluminum alloys are lightweight, corrosion-resistant, non-magnetic, and possess excellent thermal and electrical conductivity. They offer a superb strength-to-weight ratio and are generally very easy to machine, allowing for fast production and fine finishes. Different grades offer varying levels of strength, weldability, and corrosion resistance.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications.”

(Common Grades: 303, 304, 316/316L, 410, 420, 17-4 PH)

Description: Known for its excellent corrosion resistance, high strength, durability, and hygienic properties. Stainless steels can maintain their properties at high temperatures. While generally harder to machine than aluminum, specific grades (like 303) offer improved machinability. Grades like 316/316L offer superior corrosion resistance, especially against chlorides.

Good for:

Why customers love it: “Its exceptional durability, resistance to corrosion and heat, and clean aesthetic make it ideal for demanding environments and high-quality finished parts.”

(Common Grades: 1018, 1020, A36)

Description: Mild steel is a cost-effective ferrous material known for its good strength, ductility, weldability, and machinability. It is magnetic and, without protective coating, susceptible to rust. It’s a workhorse material for many structural and general engineering applications.

Good for:

Why customers love it: “It’s the go-to choice for strong, weldable, and highly cost-effective parts when corrosion resistance isn’t the primary concern.”

(Common Grades: 4140, 4340, 8620)

Description: Alloy steels contain additional elements (like chromium, nickel, molybdenum) to enhance properties like hardness, strength, toughness, wear resistance, and heat resistance compared to mild steels. Many alloy steels can be heat-treated to achieve very high strength and hardness levels. Machinability varies depending on the grade and condition (e.g., annealed vs. hardened).

Good for:

Why customers love it: “When superior strength, toughness, and wear resistance are needed, especially after heat treatment, alloy steels deliver high performance for demanding applications.”

(Common Grades: C360 (Free-Machining Brass), C260 (Cartridge Brass))

Description: Brass is an alloy of copper and zinc, known for its outstanding machinability (especially C360), good corrosion resistance, excellent electrical conductivity, and attractive gold-like appearance. It’s relatively low friction and non-sparking.

Good for:

Why customers love it: “Its unbeatable machinability allows for complex parts to be made quickly and cost-effectively, combined with good aesthetics and corrosion resistance.”

(Common Grades: C101 (OFHC), C110 (ETP))

Description: Copper is renowned for its exceptional electrical and thermal conductivity, second only to silver. It also has good corrosion resistance and machinability, although it can be ‘gummy’. It is ductile and has a distinctive reddish appearance.

Why customers love it: “For applications demanding the highest levels of electrical or thermal conductivity, pure copper is often the best choice, despite its higher cost.”

(Common Grades: Grade 2 (Commercially Pure), Grade 5 (Ti-6Al-4V))

Description: Titanium offers an exceptional strength-to-weight ratio, outstanding corrosion resistance (especially in saltwater and chemical environments), and biocompatibility. It maintains its strength at elevated temperatures. However, it is relatively expensive and challenging to machine due to its toughness and tendency to gall.

Good for:

Why customers love it: “When maximum strength with minimum weight and superior corrosion resistance are critical, titanium provides unmatched performance, especially in extreme environments.”

(Common Grades: AZ31, AZ91)

Description: Magnesium is the lightest structural metal, offering an excellent strength-to-weight ratio, even better than aluminum. It has good machinability but requires careful handling due to its high flammability risk (chips and dust). It also offers good damping capacity. Corrosion resistance is generally lower than aluminum unless treated.

Good for:

Why customers love it: “For ultimate lightweighting in structural applications, magnesium offers significant advantages over other metals, provided proper machining and handling precautions are taken.”

Plastics

Description: ABS is a common, cost-effective thermoplastic known for its good impact resistance, toughness, stiffness, and ease of machining. It has good dimensional stability and can be easily painted or bonded. Its chemical and UV resistance are moderate.

Good for:

Why customers love it: “It’s a versatile, affordable, and easy-to-machine plastic, making it excellent for general-purpose prototyping and functional parts that need good toughness.”

(Common Brands: Lexan™, Makrolon®)

Description: Polycarbonate is a strong, incredibly impact-resistant (virtually unbreakable), and temperature-resistant thermoplastic that is often optically transparent. It maintains its properties over a wide temperature range and has good dimensional stability. It’s more expensive than ABS or Acrylic and can be susceptible to scratching and certain chemicals.

Good for:

Why customers love it: “Its exceptional toughness and clarity make it ideal for applications needing high impact resistance and transparency, even at elevated temperatures.”

(Common Grades: Nylon 6, Nylon 6/6, MDS-Filled, Glass-Filled)

Description: Nylon is an engineering thermoplastic known for its excellent strength, abrasion resistance, toughness, low coefficient of friction, and good chemical resistance (especially to oils and fuels). It tends to absorb moisture, which can affect dimensional stability and mechanical properties. Additives like Molybdenum Disulfide (MDS) or glass fibers can enhance lubricity/wear or stiffness/strength, respectively.

Good for:

Why customers love it: “Its combination of strength, toughness, and excellent wear resistance makes it a top choice for durable moving parts and components subjected to friction.”

(Common Brands: Plexiglas®, Lucite®)

Description: Acrylic is known for its excellent optical clarity, weather resistance, rigidity, and wide range of available colors (including transparent, translucent, and opaque). It’s more brittle and less impact-resistant than Polycarbonate but is generally more scratch-resistant and cost-effective. It machines well to a smooth, polished finish.

Good for:

Why customers love it: “It offers glass-like clarity and excellent weatherability at a lower cost and weight than glass, and it machines to a beautiful finish.”

(Copolymer POM-C / Homopolymer POM-H)

Description: Acetal (often known by the DuPont brand name Delrin® for the homopolymer) is a high-strength, low-friction engineering thermoplastic with excellent dimensional stability, high stiffness, and good wear resistance, especially in wet environments (low moisture absorption). It’s resistant to many solvents and chemicals.

Good for:

Why customers love it: “Its combination of stiffness, low friction, excellent machinability to tight tolerances, and dimensional stability makes it ideal for precision mechanical components.”

Description: PEEK is a high-performance engineering thermoplastic offering an exceptional combination of properties: high temperature resistance, excellent mechanical strength and stiffness, superior chemical resistance, good wear and fatigue resistance, and inherent flame retardancy. It is relatively expensive and can be more challenging to machine than standard plastics.

Good for:

Why customers love it: “For extreme applications involving high temperatures, aggressive chemicals, or demanding mechanical loads where other plastics fail, PEEK delivers outstanding performance.”

Description: PVC is a widely used, cost-effective plastic with good chemical resistance (especially to acids and bases), good electrical insulation properties, and inherent flame retardancy. It is relatively rigid and durable. Machinability is fair, but dust control is important. UV resistance may require stabilizers.

Good for:

Why customers love it: “It offers excellent chemical resistance and electrical insulation at a very competitive price point for a wide range of industrial applications.”

Our team uses 5-axis machining technology to create even the most complex parts with amazing accuracy. This means your parts will:

Need parts quickly? We understand! Our rapid prototyping service can deliver your first parts in as little as 3 days. This helps you:

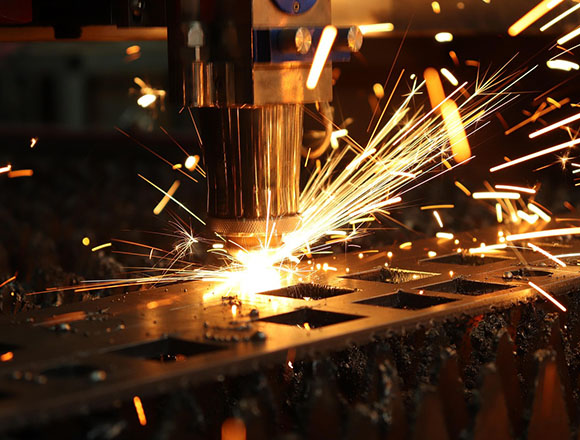

We use many different methods to create your parts:

Our CNC milling machines shape your parts with rotating cutting tools, while our CNC turning process is perfect for round parts. Both give you:

For special projects, we also offer:

Our CNC services help make important parts for:

At Istar Machining, quality isn’t just a word – it’s how we work every day. We check every part using:

This means your parts will meet or beat your specifications every time.

Getting started is simple:

Our team includes engineers who can help improve your designs to:

Beyond just machining, we offer:

Ready to experience the Istar Machining difference? Our CNC prototype machining services can bring your ideas to life quickly and accurately.

Contact us today to:

Don’t settle for less than perfect parts. Choose Istar Machining – your partner for precision industrial CNC machining services!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or