Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

An injection mold can be a great tool. But it can also be an expensive mistake if you do not know what it is all about. In this post, I will show you the good parts and the bad parts. We will look at the good things and the bad things about injection molding. When you finish reading, you will know if an injection mold is the right choice for what you want to make. This knowledge will help you save your time and money.

Let’s begin with the simple facts. Think about a special block of metal. This block has a hole inside it. This hole is called a cavity. The cavity has the exact shape of the part you want to make. This metal block is your injection mold. The way it works sounds simple.

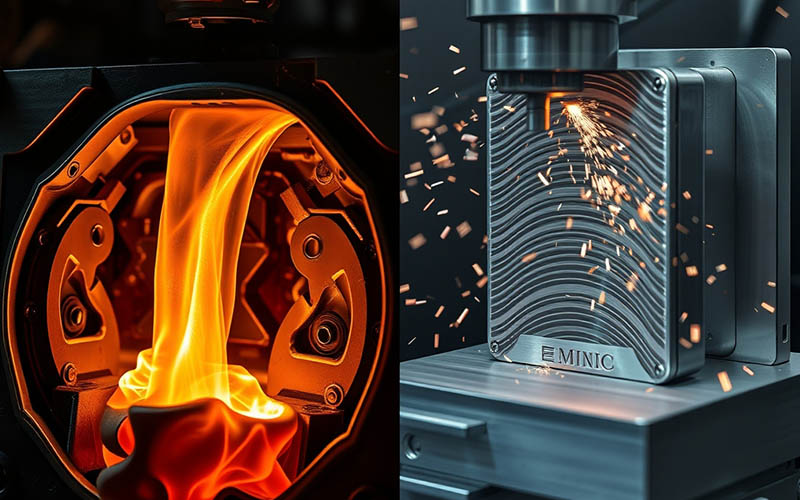

The process involves injecting molten plastic into this mold. This is done with a lot of force, called high pressure. The hot, liquid plastic goes into every small corner of the mold. After the plastic is in the mold, it begins to get cool. As it gets cool, it turns into a solid plastic piece. The mold then opens, and the new part is pushed out. This step is called ejection. It gets the part out so the mold can shut again. After that, the whole thing starts again. This is how you make plastic parts with an injection mold. The mold is the special tool that creates the parts.

This is where the real benefit is. The top reason people use an injection mold is to make high volumes of parts. Imagine making thousands, or even millions, of the very same part. The process is very quick. A single cycle can be very short. A cycle is the time it takes from pushing plastic in to getting a finished part out. Sometimes a cycle is less than 60 seconds long. This quick cycle time means you can produce many parts per hour.

This speed makes the process a good value for the money when you have big production runs. It is true that the first injection mold is not cheap to make. But when you divide that cost by thousands of parts, the cost per part is very small. The more parts you make, the less each one costs. This is one of the biggest good things about injection molding. It is a wonderful way to make things when you need to make them fast and at a low cost for each one. The cost per part is much lower than with many other ways of making things.

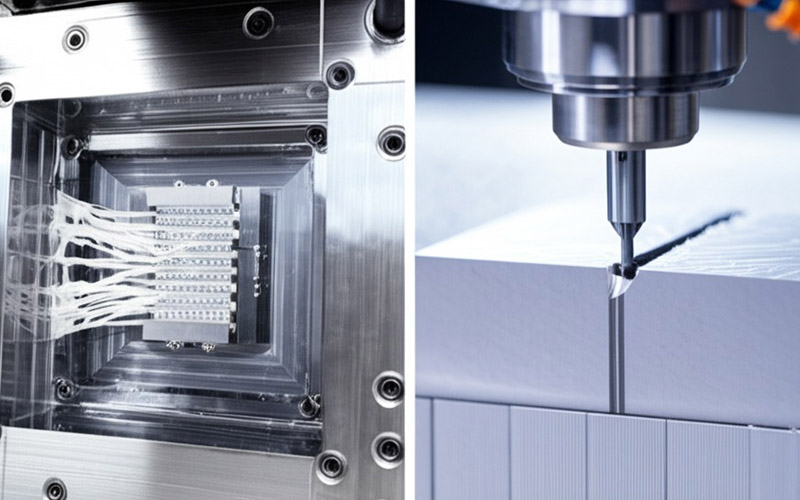

Yes, you can! This is another big plus. An injection mold lets you make parts with lots of small details. The plastic is pushed in with high pressure. Because of this, it can fill up tiny, fancy parts of the mold cavity. This means you can create intricate shapes and fancy geometry. It would be hard to make these shapes any other way. You can design a part with very small details, and the injection mold can make it perfectly over and over.

Just think about the plastic parts in your car or inside your phone. They often have a complex shape with special features. These are all made with an injection mold. The mold is made with great care, so the final part is also very exact. You do need to think about some design rules, like draft angles. These help the part come out of the mold. You also have to be careful with things like an undercut, which can make the mold harder to build. But if you want to make a detailed shape, a good mold is one of the best tools.

When you make a product, you want each one to be just like the last. An injection mold is amazing at this. This repeatable process gives you high repeatability. This means the first part you create with a mold will look just like the ten-thousandth part. This is very important to make sure your product works well and has good quality. The mold is a strong piece of steel or aluminum. It does not change over time.

This high repeatability makes sure that your parts will fit together. It also makes sure they will work like you planned. This process can make parts with very high tolerances. This means the parts are very accurate. Every single part that comes from the injection mold is an identical plastic copy. You can set up the machine and just let it run. You can even automate the work so it runs by itself. This ability to make highly repeatable parts is a big reason why this manufacturing process is so well-liked for producing plastic products.

You have a lot of freedom when you pick a material. You are not limited to only one kind of plastic. There are thousands of different plastic materials you can use. You can pick a resin based on what your part needs to do. Does the part need to be very strong? Does it need to bend? Or does it need to handle heat? There is a type of plastic for that job. Very common plastics like PP or ABS are used often.

You can also put additives into the plastic. You can use fillers, like small pieces of glass, to add strength to the completed part. This can give greater strength to the completed part. You can also add color pellets called masterbatches. This lets you color the plastic any way you like. This helps you make a final part that looks and works just how you imagined. You will not need to do much post-production work, like painting. The color is already inside the plastic. This choice of many plastic materials is a great benefit of using an injection mold.

So far, this process sounds wonderful. But there is a very big problem. The number one drawback is the cost you pay at the start. The initial costs are high. Making the injection mold, which is also called the tool, costs a lot of money. A simple mold can cost a few thousand dollars. A fancy mold for a big part can cost much, much more. These high tooling costs stop many people from using this method.

This cost is high because it takes a lot of work to make the tool. The injection mold is most often made from steel or aluminum. It must be cut very carefully. This is usually done with a CNC machine. It takes a lot of time and a lot of skill. Because the first payment for the mold is so big, this process is not good for small production runs. If you only need a few hundred parts, the high cost of the mold will make each part very expensive. This is one of the main disadvantages of injection molding.

Another problem is the time it takes. It can take a long time from when you finish your design to when you get your first parts. The lead times for making an injection mold are usually long. It can take many weeks to produce one mold. A more difficult steel tool can take a few months. This is because making the mold is a slow and careful job.

The mold begins as a solid block of metal. A person with special skills uses CNC machines and other tools. They carefully cut the part’s cavity into the metal. The mold must be made perfectly. Any small defect or mistake in the mold will be copied onto every part it makes. This long process means you cannot get your injection-molded parts in a hurry. If you need parts fast, the long turnaround times for making the mold can be a serious issue. This is very different from 3D printing, where you can get a part in just a few hours.

This is a very important thing to know. After your injection mold is made, it is very hard and expensive to make changes. A mold is cut out of solid metal. If you need to make design changes, it is not as easy as changing a file on a computer. If you want to add plastic to your part, you have to cut away more metal from the mold. That might be possible. But what if you want to make a part of your design smaller? You cannot easily add metal back to the mold.

In many cases, even tiny design changes mean you need to build a brand new injection mold. This makes the process not very flexible. You must be completely sure your design is final before you pay for the tool. This is why a lot of people use 3D printing or CNC machining. They use these to make test parts first. They check the design very well before they spend a lot of money on a costly mold. The fact that it is hard to make design changes is a big risk you need to think about.

It is useful to see how injection molding stands up against other ways of making things. 3D printing and CNC machining are two other popular ways. Let’s look at the good and bad points, or pros and cons, of each one. 3D printing is wonderful for making just one part or for small production. It does not cost much to get started. But each part costs a lot to make, and it is slow if you need to make many parts.

CNC machining is somewhere in the middle. It can create strong, exact parts from metal or plastic. It is faster than 3D printing for some jobs. But it is still slower than an injection mold when you need high volumes. The plastic injection process is the best for making a huge number of parts. It has the highest cost at the start. But it has the lowest cost per part when you make thousands of parts.

Here is a simple table to show the differences:

| Feature | 3D Printing | CNC Machining | Injection Molding |

|---|---|---|---|

| Starting Cost | Very Low (Just the machine) | Medium (Machine, setup) | Very High (The injection mold) |

| Cost Per Part | High | Medium | Very Low (for high volumes) |

| Speed | Slow | Medium | Very Fast (for production runs) |

| Design Changes | Very Easy (Change the file) | Easy (Change the program) | Very Hard (Need a new mold) |

| Materials | Good range of plastics | Wide range of plastics and metals | Huge range of plastics |

This table helps show that the best way to make something depends on what you need. For a test part or just a few parts, you should use CNC or 3D printing. For making things in large numbers, the injection mold is very often the best pick.

So, how do you make the final choice? It all depends on the answers to a few key questions you must ask yourself about your plan to make a product. First, how many parts do you need to make? If your answer is “thousands or more,” then an injection mold is a very good option. The process is made for high production. If you only need a small number of parts, you should look at 3D printing or CNC.

Second, is your design completely finished? If you are still testing it and think you might make design changes, do not spend money on an expensive steel mold. Use a cheaper method to test your ideas first. You could even use a softer, less expensive aluminum or aluminium mold for a smaller test run. This lets you check the design before you make the final steel tool. The mold is a very big purchase.

Last, think about what material you need. An injection mold offers you amazing choices for plastic. You can also get parts with great detail and high repeatability. If these things are important for your product, and you need enough parts to make the mold cost worthwhile, then you have found your answer. The advantages and disadvantages of injection are now clear. It is a great tool, but only for the right kind of job. Think about the good and bad points with care before you decide.