Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you feeling stuck trying to pick the right manufacturing process? Do you worry about high costs and long lead times? Are design limitations giving you headaches? At Istar Machining, we understand these challenges and offer expert CNC machining services that can help overcome the limitations of injection molding.

Let’s look at what injection molding offers and why our precision CNC machining might be a better fit for your needs.

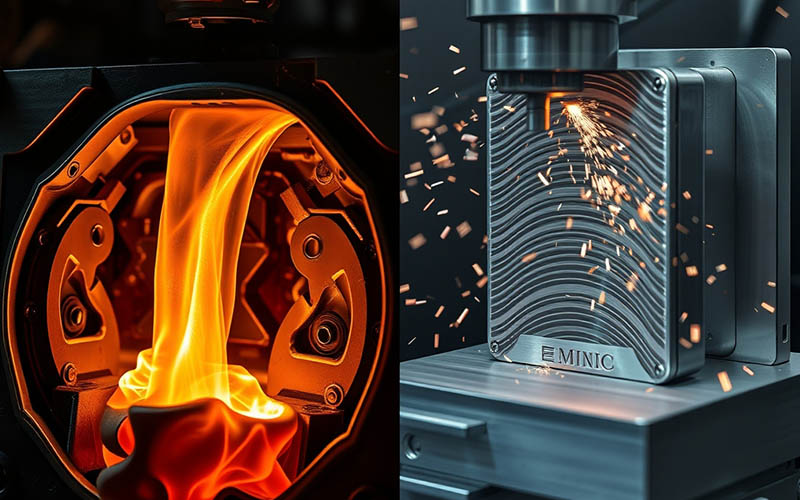

Injection molding is a way to make parts. Hot plastic goes into a mold. The plastic cools. Then you get many same parts fast.

Do you know how much money you need to start injection molding? The numbers are scary:

This is painful for small runs and new products. You pay all that money before you make one real part!

Are you tired of hearing “we can’t make that”? Injection molding has many rules:

This blocks your creativity and limits what you can design.

Worried about waste? Injection molding has problems:

Your green goals get harder with these facts.

| Good Things | Bad Things | Key Facts |

| High speed production | Very high start cost | Tooling: $10,000-$100,000 |

| Good for many same parts | Long wait for molds | Lead time: 4-12 weeks |

| Works with many plastics | Design must follow strict rules | Need 1-2° draft angles |

| Low cost per part (at high volume) | Wastes material | 15-30% material waste |

| Makes smooth parts | Uses lots of energy | 0.5-1.5 kWh per kg |

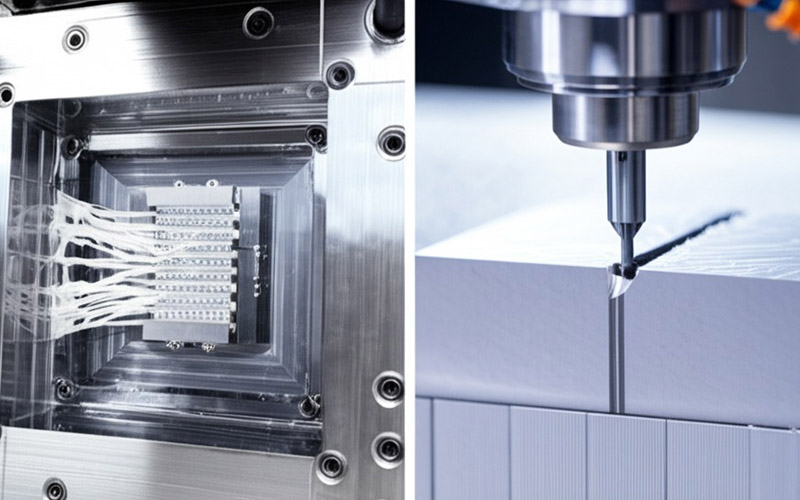

Good news! Our custom CNC machining services fix the big problems with injection molding:

With our rapid CNC machining, you get:

Our 5-axis machining opens up new design options:

We offer:

A medical device maker came to us after getting a $45,000 quote for injection molding. They needed:

With our medical CNC machining service, we delivered:

They saved $33,000 and got parts 10 weeks faster!

Be honest – injection molding is still good in some cases:

Our CNC milling and CNC turning services are better when:

| Material Type | Good For | CNC Available? | Injection Molding Available? |

| ABS | Impact strength | Yes | Yes |

| PP | Chemical resistance | Yes | Yes |

| Aluminum | Lightweight strength | Yes | No |

| Titanium | High strength, medical | Yes | No |

| Stainless Steel | Food safe, strong | Yes | No |

The aerospace field needs exact parts. Our aerospace CNC machining delivers:

Medical parts must be perfect. Our services provide:

Car parts need strength and speed. We offer:

Ready to skip the high costs and long waits of injection molding? Here’s how to get started with Istar Machining:

Injection molding locks you in with high costs, long waits, and strict design rules.

Our CNC machining frees you with no tooling costs, fast delivery, and design freedom.

When speed, flexibility, and avoiding big upfront costs matter, CNC machining services from Istar Machining are the smart choice.

Don’t get trapped by the old way of manufacturing. Contact us today and see how our solutions can save you time, money, and stress!