Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Have you ever sought out at the skies and wondered just how a substantial airplane remains in the air? I sure have. The magic behind it is the jet engine, a marvel of engineering. For years, I’ve been amazed by these effective equipments. In this short article, I’m going to take you on a journey inside a jet engine. We’ll check out all the major components, from the air intake to the exhaust. I’ll discuss what each part does and just how they all work together to develop the incredible thrust that powers an airplane.

A modern jet engine has numerous major components that collaborate. Think of it like a group where each gamer has a special job. The main parts of a jet engine are the air intake, the compressor, the combustion chamber, the turbine, and the exhaust nozzle. Each one of these is vital for the jet engine to produce the thrust needed to fly an aircraft.

The entire procedure is a cycle. Air is available in the front, obtains pressed by the compressor, combined with fuel and melted in the combustion chamber, and after that blew up out the back via the turbine and nozzle. This produces the effective press, or thrust, that relocates the airplane ahead. The jet engine is a kind of gas turbine engine. This suggests it makes use of hot gas to rotate a turbine. The turbine’s work is to power the compressor. It’s a clever, continuous loop that makes the jet engine so effective and reliable. Comprehending these major components is the primary step to recognizing the jet engine itself.

The journey of air with a jet engine begins at the air intake. The air intake, or inlet, is the very front part of the jet engine. Its job is to catch the incoming air and guide it into the compressor. It looks straightforward, however its design is really vital. The form of the air intake aids to reduce the air. You might believe we want the air to scoot, but the compressor requires the air to be relocating at a slower speed to function right.

The layout of the air intake duct is important for the efficiency of the jet engine. For an aircraft flying at less than the speed of sound, the duct is usually an easy, smooth tube. However, for an airplane that flies at supersonic speed, the air intake is much more complicated. It has a special form with ramps or cones to reduce the supersonic air movement to a subsonic speed prior to it goes into the compressor. This process is really essential to avoid a problem called a stall in the compressor, which might trigger the jet engine to stop working. The air intake should supply a consistent flow of air to the compressor at any speed or elevation.

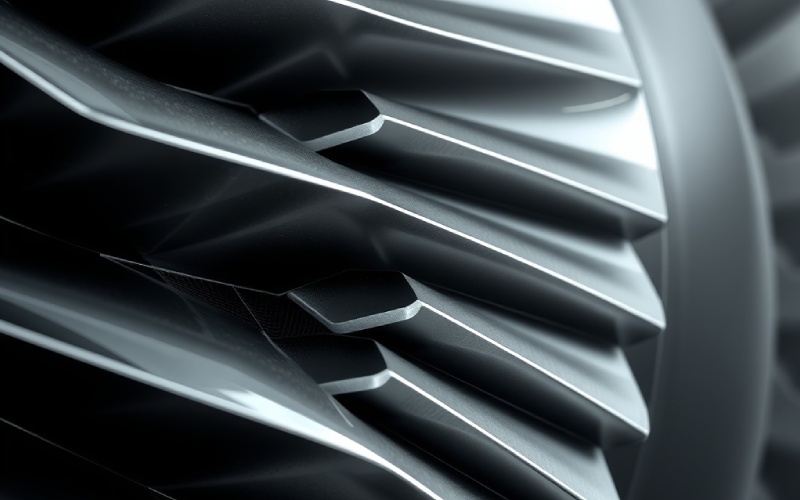

I like to call the compressor the heart of the jet engine since it’s where the air gets squeezed. The compressor has many rows of small spinning blades called rotor blades and fixed blades called stator vanes. As air flows through the compressor, each row of blades presses it a growing number of. This is called compression. By the time the air leaves the compressor, its pressure is much higher. This high-pressure air is what the jet engine requires for the next action.

There are 2 main types of compressors: axial and centrifugal. In an axial compressor, the air flows directly through the engine, alongside the shaft. This is the most common kind utilized in modern-day jet engines for large aircraft. A centrifugal compressor tosses the air outwards, away from the facility. This type is often made use of in smaller sized jet engines. The compressor is attached to the turbine by a shaft. The turbine, which is spun by the hot gases, offers the power to turn the compressor. A lot of power is required to run the compressor in a huge jet engine. Actually, the compressor makes use of the majority of the power produced by the turbine section.

| Compressor Type | Air flow Instructions | Common Usage |

|---|---|---|

| Axial | Straight with, alongside the shaft | Large jet engines for aircraft |

| Centrifugal | External from the center | Smaller sized jet engines, helicopters |

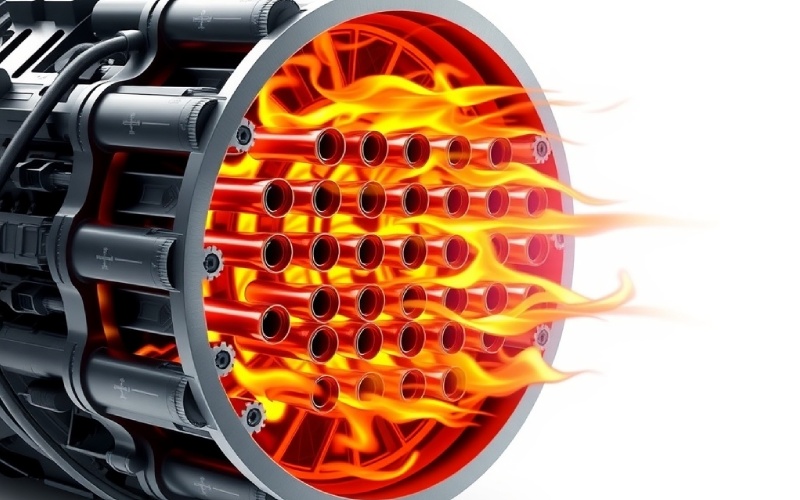

After the compressor, the high-pressure air goes into the combustion chamber. This is where the genuine fire and fury of the jet engine happens. In the combustion chamber, the air is blended with fuel and stired up. A special igniter, like a spark plug in an auto, is used to light the mixture when the engine starts. Once it’s lit, the fire burns continuously. The fuel is sprayed into the combustion chamber via lots of small nozzles to make certain it mixes well with the air.

The temperature inside the combustion chamber can get extremely warm, reaching over 2,000 ° C. This extreme home heating triggers the air to broaden swiftly. The style of the combustion chamber, additionally called a combustor, is very vital for burning effectiveness. We want all the fuel to burn totally to obtain one of the most power from it. The warm, high-pressure gas that is created in the combustion chamber is the power source for the jet engine. This gas then rushes into the turbine area.

The turbine is right after the combustion chamber, so it obtains hit by the super-hot gases. The turbine’s job is to take several of that power from the warm gas to power the compressor. It does this with numerous rows of turbine blades that look like little wings. As the warm gas streams past the turbine blades, it makes them rotate at a very high speed. This spinning motion is transferred to the compressor with a long shaft that attaches them. The generators which drive the compressor are a crucial part of the jet engine.

The turbine blades have to be really strong to take care of the high temperature and rate. They are made from unique metals and commonly have a ceramic finishing to safeguard them. To prevent the turbine blades and turbine disc from melting, amazing air is bled from the compressor and routed through tiny holes in the blades. This amazing air forms a slim safety layer over the surface area of the blades. This cooling system is a crucial part of the jet engine’s style. Without it, the turbine would not be able to endure the extreme heat from the combustion chamber.

After passing through the turbine, the hot gas still has a lot of power. This gas then moves into the exhaust area of the jet engine. The exhaust nozzle is the really back component of the jet engine. Its main job is to take the warm, high-pressure gas and shoot it out the back at a very high speed. According to Newton’s 3rd legislation of activity, for every activity, there is an equivalent and opposite response. The activity of the gas shooting rearwards creates the thrust that presses the airplane onward.

The shape of the exhaust nozzle is extremely vital. For aircraft that fly at subsonic speeds, a basic, convergent nozzle that obtains narrower at the end is used. This form aids to accelerate the exhaust gases. For supersonic airplane, an extra complex convergent-divergent nozzle is frequently made use of. This type of nozzle can handle the extremely high speed and temperature level of the exhaust gas and create much more thrust. Some jet engine designs additionally have a mixer in the exhaust to mix the hot core air with the cooler air from the bypass duct. This can make the jet engine quieter and more effective.

Yes, a jet engine can get too warm. Managing temperature level is one of the biggest challenges in jet engine layout. The combustion chamber and the turbine area are the hottest components. If these parts obtain too warm, they can be damaged or even thaw. To stop this, designers have actually developed clever means to cool down the jet engine. As I stated, one usual method is to utilize bleed air from the compressor.

This cool air is directed through a series of pipelines and ducts to the hot components of the engine. For example, it is made use of to cool down the turbine blades, the turbine disc, and the within walls of the combustion chamber. This system assists to maintain the temperature level of these major components within a safe functional array. The air conditioning systems in a contemporary jet engine are extremely intricate and are a huge reason why these engines are so trusted and can run for thousands of hours. The consistent air flow with the engine likewise assists to lug away some of the heat.

Some military airplane require an additional ruptured of rate, especially during takeoff or in fight. This is where an afterburner comes in. An afterburner is an additional section added to the back of the jet engine, after the turbine and before the exhaust nozzle. It’s primarily a lengthy pipe where much more fuel is splashed straight right into the hot exhaust gas and stired up. This develops a massive amount of additional thrust.

When the afterburner gets on, you can see a large flame coming out of the rear of the jet engine. It’s a very powerful device, yet it likewise makes use of a great deal of fuel. That’s why it’s just made use of for brief durations when maximum thrust is needed to get to supersonic speed. The afterburner can enhance the thrust of a jet engine by 50% or more. However, it likewise greatly enhances the temperature of the exhaust gases, so the afterburner and the nozzle need to be made from materials that can endure this severe heat.

We have actually discussed the main shaft that links the compressor and turbine. This shaft is the foundation of the jet engine, moving the mechanical energy from the turbine to the compressor. Yet there’s another important part called the accessory transmission. The jet engine does not simply offer thrust for the aircraft; it likewise powers many of its other systems.

The accessory gearbox is connected to the major shaft with a set of gears. It resembles the power-take-off on a tractor. It drives things like:

So, while the major work of the jet engine is to develop thrust, it additionally serves as a nuclear power plant for the whole airplane. The shaft and gearbox are vital for making this happen.

Rolls-Royce and General Electric are 2 of the most significant names in the jet engine world. I have actually had the chance to research jet engine designs from both business, and while they all deal with the same basic principles, there are some interesting style distinctions. One remarkable distinction remains in the variety of shafts.

Numerous General Electric jet engines utilize a two-shaft layout. This means there is one shaft connecting a low-pressure compressor and a low-pressure turbine, and a 2nd, separate shaft for the high-pressure compressor and high-pressure turbine. Rolls-Royce is well-known for its three-shaft jet engine design. This adds an intermediate-pressure compressor and turbine, each by itself shaft. The concept behind the three-shaft style is that each compressor and turbine area can spin at its own best rate, which can make the jet engine extra reliable. Both layouts have their advantages and disadvantages, and both firms make incredibly trustworthy and effective jet engines.