Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

People talk about a jig and fixture like they are the same. This is an easy mistake to make. Both of them are special tools. They help us make things in a better and faster way. But a jig and a fixture actually do jobs that are very different. If you understand this difference, you can understand how we build nearly everything we see. In this post, I will tell you about the one simple thing that makes a jig different from a fixture. After you learn it, you will not get them mixed up anymore.

Let’s begin with the simple things first. In a busy workshop, the main goal is to make a lot of parts that are exactly the same. If you do this by hand, you have to measure every time. This is slow. It can also cause you to make mistakes. This is why a jig and fixture are so helpful. These two tools are special things that are made to fix this very problem. They are tools used to hold a part. This part is called a workpiece. They get it ready for work to be done on it.

Many people who do this work often say jig and fixture mean the same thing. These terms are often used interchangeably. But they are not the same tool. A jig and fixture are both used during the production process. But they work with the tools in different ways. Both a jig and a fixture help make the work faster and more correct. But you need to know which one to use for the job you are doing.

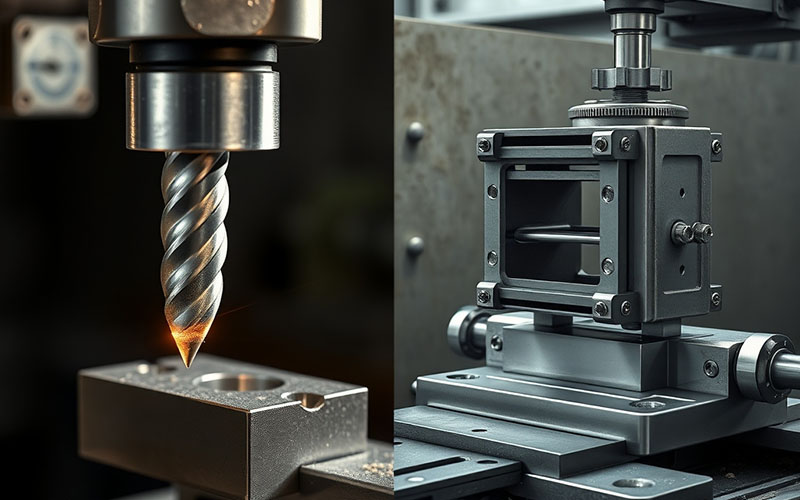

Now, let’s talk about the first tool. This tool is the jig. A jig has two jobs. The first job of a jig is to hold the workpiece. It has to hold the workpiece in the perfect, correct position. But the second job is what makes a jig special. A jig also guides the tool that is doing the work. This is the biggest thing you need to remember about a jig. It helps guide the cutting tool.

Picture this. You need to drill a hole in the very same spot on 100 blocks of wood. A jig would be the perfect tool for this job. The jig would have a hole in it. Inside the hole is a hard metal ring. This ring is called a bushing. You would put the jig on your block. Then, the bushing would guide your drill bit to the perfect spot. You do not need to measure anything. The jig finds the spot and guides the tool for you. Jigs can also be used to guide a tool to tap a hole. Tapping a hole means cutting threads on the inside of it. A jig helps you do the job fast and perfectly every single time.

Now we can look at the second tool. This tool is the fixture. A fixture is more simple than a jig. A fixture has just one main job. Its job is to hold a part safely in one spot. That’s it. A fixture holds the workpiece in one place and in one direction. It uses a clamp or something similar. This makes sure the part does not move when a machine is working on it. These devices that hold parts are very important.

A fixture is different from a jig. A fixture does not guide the tool. The machine, such as a CNC machine, already knows where it needs to go. The fixture only needs to hold the part still in a place that is known. So, let’s say you need to mill the top of a metal block. You would use a fixture for this. The fixture would lock the block down to the table of the machine. The milling cutter on the machine would then move across the block. It would not touch the fixture. The fixture would not guide it. Fixtures are used in many places. Fixtures hold parts for many different kinds of jobs.

I have now told you about each tool. By now, you can likely see the one big thing that makes them different. The main difference between jigs and fixtures has to do with guiding the tool.

That is the main secret. If the tool you see has something like a bushing that guides a drill or another tool, then it is a jig. If it only holds the part down so a machine can do work on it, then it is a fixture. Every jig and fixture has a job to do. But only the jig does that extra job of guiding the tool.

Here is a simple table to help you remember:

| Feature | Jig | Fixture |

|---|---|---|

| Holds the Workpiece? | Yes | Yes |

| Locates the Workpiece? | Yes | Yes |

| Guides the Cutting Tool? | Yes | No |

| Common Operations | Drilling, Tapping, Reaming | Milling, Grinding, Welding |

So, why do we need these tools? From what I have seen, using jigs and fixtures is the secret to making things in the modern world. They are the reason we can do mass production. When you use a jig or fixture, every workpiece is held in the very same way. This gives you high repeatability. This means every part that is made is almost exactly the same. This idea is called interchangeability. It is very important.

Using a jig or fixture also makes productivity much higher. A worker does not need to use time to measure and mark every part. They can simply put the part in and start the machine. This lowers the chance of human error. It also makes the whole job go faster. It also makes manufacturing precision better. Parts are made with a very tight tolerance. This means they are very, very close to the perfect size.

Yes, I can. The most common type of jig I have seen is a drill jig. Let’s return to our example about drilling holes in blocks of wood. A simple plate jig can just be a flat piece of metal. It will have holes drilled in it. You would clamp this jig onto the block of wood. The holes in the jig would guide your drill bit. This makes sure that you drill a hole in the same place on each and every block.

This type of jig is used for more jobs than just drilling. It can be used for any job where a tool must be guided. An example is drilling and tapping. You could have a jig that first guides a drill bit. Then, it can guide a tap to make threads. The jig makes sure that both of these jobs happen in the perfect place. The person running the machine only needs to change the tool. This kind of jig saves a lot of time.

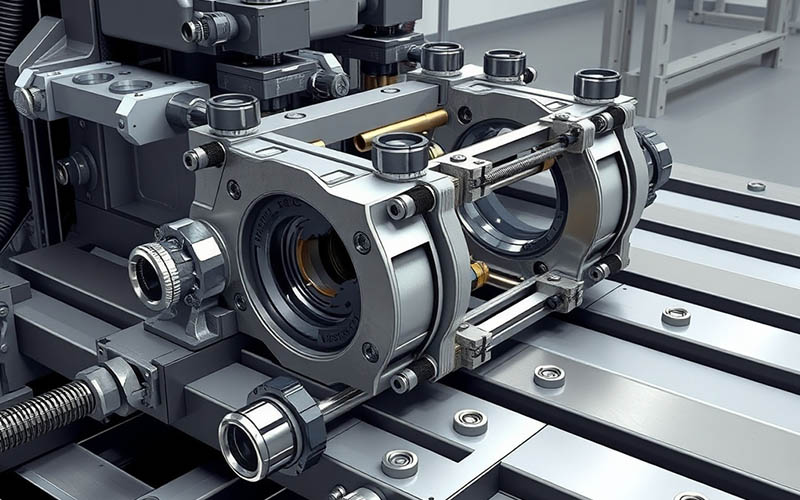

Fixtures are like the quiet heroes for big, heavy jobs. You can find them anywhere a machine needs to do something very exact to a part. They are very important for machining operations. For instance, when you need to mill a flat surface or grind an edge on a part, you have to use a fixture. The fixture holds the part on the table of a CNC machine. It stays there while the spinning cutter does its job.

I have also seen many fixtures that are used when putting things together. Just think about an automobile assembly line. When a robotic arm needs to weld a car door, a big fixture is used to hold a product in the perfect position. This fixture will hold a product in place. This allows the robot to do the very same weld again and again. This whole welding and assembly process would not be possible without the hardworking fixtures that keep everything from moving. A fixture is very, very important.

When I think about the good things about using a jig, three words pop into my head. They are speed, being correct, and being simple. A jig helps to speed up the production process a lot. The jig locates the workpiece and also guides the tool. Because of this, a worker with less skill can still make parts that are very good. This is one of the main advantages of jigs.

Because it is simple, there is less need for a lot of training. A good jig can make a hard job into a simple one. Jigs can also be made to be very safe. They can protect the worker’s hands from the cutting tool. Over time, jigs and fixtures have made making things a lot less dangerous. A simple jig can make a big difference in how a workshop runs. A jig is a very smart tool.

A fixture that is made well is extremely valuable. A good fixture design is very important for quality and for safety. First of all, fixtures align the workpiece perfectly with the machine tool. This is a key part of the whole machining process. The hardworking fixtures that secure the part need to be strong. They have to fight the forces from cutting so they do not move even a little bit.

Safety is another very big benefit. Fixtures need to hold the part so safely that it cannot come loose. It must not fly out of the machine. Fixtures are made from strong stuff like steel or aluminum. This makes sure they are strong enough for the job. To put it simply, fixtures have made manufacturing processes much more dependable. They are critical manufacturing tools that enable us to make difficult parts in a safe way. A great fixture helps you make a great part.

Creating jigs and fixtures is very different now than it was in the past. The old way is to make them out of metal. Machining is the most common way to do this. This common manufacturing process for creating a jig and fixture means you use a machine. Machines like a mill or a lathe are used. They shape a block of metal into the tool you need. This makes the jig or fixture very strong. It also makes it last for a long time.

But now, we have new choices. 3D printing has become a well-liked way to make a jig and fixture. For jobs that are not so heavy, 3D printed jigs and fixtures can be made in just a few hours. This is much faster than days or weeks. This is a fast and low-cost manufacturing process for creating jigs and fixtures. It’s good for making first examples or for small batches of parts. After parts are finished, we can use new tools like optical and laser scanning. We use them to check if the parts are good. We sometimes use laser scanning to assess manufacturing correctness. This job of scanning to assess manufacturing quality helps make sure the final part is perfect. The world of the jig and fixture is always changing. These jigs and fixtures are manufacturing necessities.

I hope this has made things more clear for you. The world of the jig and fixture is easy to understand once you know the secret. Here are the most important points to take away: