Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

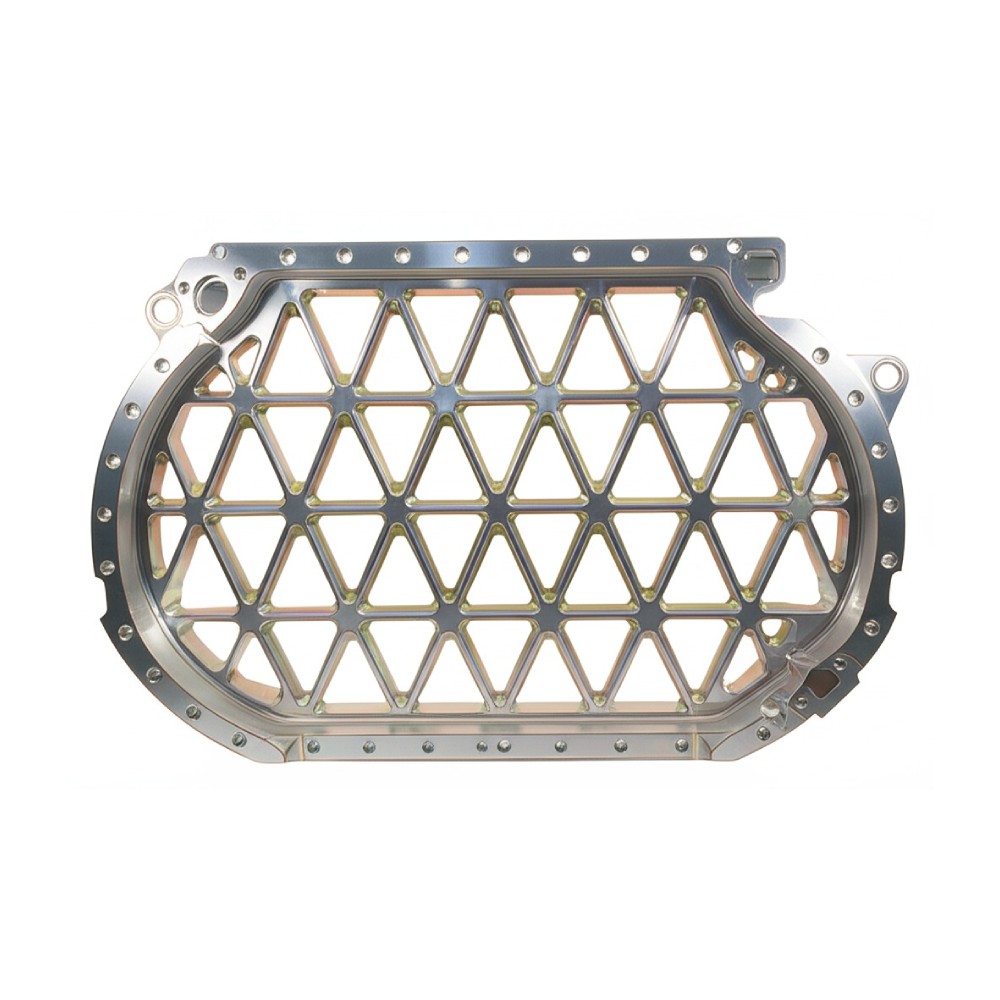

At Istar Machining, we tackle the biggest machining challenges with our advanced large CNC machining capabilities. Our industrial-strength equipment handles massive parts that smaller shops simply can’t manage. When your project demands both size and precision, our team delivers results that stand up to the toughest requirements.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

We can work with almost any material your project requires:

Metals

Highly versatile and strong, steel is a cornerstone material for large structural components, heavy machinery frames, molds, and fixtures. We machine various grades of carbon and alloy steels, tailored for strength, hardness, and wear resistance required in large-scale applications.

Common Grades/Types:

Carbon Steel: 1018, 1045, A36, A516

Alloy Steel: 4140, 4130, 4340, 8620

Common Surface Treatments: Painting, Powder Coating, Black Oxide, Zinc Plating, Nickel Plating, Chrome Plating, Nitriding, Carburizing, Anodizing (for specific steel alloys), Passivation, Heat Treatment (Annealing, Normalizing, Quenching & Tempering).

Valued for its excellent corrosion resistance, strength, and hygienic properties. Ideal for large components used in harsh environments, such as chemical processing, energy sector equipment (e.g., turbine parts), food processing machinery, and large architectural elements.

Common Grades/Types: 303, 304/304L, 316/316L, 410, 416, 420, 17-4PH, Duplex Stainless Steels.

Common Surface Treatments: Passivation (critical for enhancing corrosion resistance), Electropolishing, Bead Blasting, Brushing, Mirror Polishing, Pickling (post-welding/heat treatment).

Offering an exceptional strength-to-weight ratio, good machinability, and corrosion resistance, aluminum alloys are crucial for large aerospace structures, automotive frames, large electronic enclosures, and lightweight tooling or fixtures.

Common Grades/Types: 2024, 5052, 6061-T6/T651, 7075-T6/T651, MIC-6, ATP-5 (Cast Tool & Jig Plate).

Common Surface Treatments: Anodizing (Type II Clear/Color, Type III Hardcoat), Chromate Conversion Coating (Alodine/Chem Film), Powder Coating, Painting, Brushing, Polishing, Laser Etching.

Known for their superior strength-to-weight ratio, excellent corrosion resistance, and high-temperature performance. Titanium is often specified for demanding large applications in aerospace (e.g., airframe components, landing gear), defense, and high-performance industrial equipment.

Common Grades/Types: Grade 2 (Commercially Pure), Grade 5 (Ti-6Al-4V), Grade 9 (Ti-3Al-2.5V).

Common Surface Treatments: Anodizing (Type II for color/wear, Type III for enhanced wear), Passivation, Heat Treatment, Shot Peening, Thermal Spray Coatings (for specific wear or thermal barrier needs).

Provides excellent machinability, superior vibration damping, compressive strength, and cost-effectiveness for large, heavy parts. Commonly used for machine bases, engine blocks, large gear housings, pump bodies, and other heavy equipment components requiring stability.

Common Grades/Types:

Grey Iron: ASTM A48 (e.g., Class 30, Class 40)

Ductile Iron: ASTM A536 (e.g., 60-40-18, 80-55-06)

Common Surface Treatments: Painting, Powder Coating, Blackening, Phosphate Coating, Stress Relieving (heat treatment is crucial for dimensional stability of large castings).

Our capabilities extend beyond the metals listed above. We also have experience machining large components from materials such as Copper alloys (Brass, Bronze), Nickel alloys (Inconel®, Monel®), Superalloys, and more.

Examples of Other Metals & Grades:

Brass: C360 (Free-Cutting Brass)

Bronze: C932 (Bearing Bronze), C954 (Aluminum Bronze)

Nickel Alloys: Inconel® 625, Inconel® 718, Monel® 400

Surface Treatments: Highly dependent on the specific alloy; common options include plating, passivation, and specialized coatings. Please contact us to discuss your specific large-scale metal machining requirements.

Plastics

Known for its excellent machinability, high stiffness, dimensional stability, low friction, and good wear resistance. Ideal for large precision components, large bushings, rollers, conveyor parts, and complex fixtures.

Common Grades/Types: POM-C (Copolymer, e.g., Celcon®), POM-H (Homopolymer, e.g., Delrin®), PTFE-filled (for enhanced lubricity), Glass-filled.

Common Surface Treatments: “As-machined” finish is often sufficient. Mechanical polishing for smoother surfaces. Difficult to bond or paint without specialized surface preparation/primers.

Offers exceptional abrasion resistance, high impact strength, and low coefficient of friction. Often machined into large wear strips, chute liners, guide rails, and components for material handling systems.

Common Grades/Types: Virgin (Natural), Reprocessed, Anti-static grades, various colors.

Common Surface Treatments: “As-machined” finish. Its inertness and low friction make adhesion of coatings or paints very difficult.

Features high impact strength, good temperature resistance, and dimensional stability. Suitable for machining large protective guards, housings, large transparent prototypes (machining affects clarity), and structural elements requiring toughness.

Common Grades/Types: Machine Grade PC, General Purpose PC, UV-stabilized PC, Glass-filled PC.

Common Surface Treatments: “As-machined” finish. Vapor polishing can improve clarity on machined surfaces (more common for smaller parts). Can be painted with appropriate primers. Anti-scratch coatings can be applied.

A high-performance thermoplastic with excellent mechanical strength, high temperature resistance, chemical inertness, and wear resistance. Used for demanding large components in aerospace, medical, energy, and semiconductor industries.

Common Grades/Types: Unfilled (Virgin), Glass-filled (e.g., PEEK GF30), Carbon-filled (e.g., PEEK CF30), Bearing Grade (e.g., PEEK HPV with Carbon Fiber, Graphite, PTFE).

Common Surface Treatments: “As-machined” finish. Annealing for stress relief is common. Due to its chemical inertness, surface coating is specialized and not typical.

We can also machine other large plastic parts from materials like ABS, PVC, PTFE (Teflon®), Acrylic (PMMA), Polypropylene (PP), and more.

Examples of Other Plastics & Grades:

ABS: General Purpose, Flame Retardant

PVC: Type I (Rigid), Type II (High Impact)

PTFE: Virgin, Glass-filled, Carbon-filled

Acrylic (PMMA): Cast, Extruded

Surface Treatments: Varies significantly by plastic type. Some (like ABS, Acrylic) can be polished or painted. PTFE is very inert. Contact us to discuss your specific large-scale plastic machining and finishing needs.

Our large CNC machining services help many different industries create their biggest, most important parts:

When you work with Istar Machining, quality isn’t just a goal – it’s a guarantee:

Our massive 5 axis machining centers can create almost any shape or feature in your large parts:

Every large part undergoes thorough testing:

Our large CNC machining service is more environmentally friendly than you might think:

Even on massive parts, we maintain tolerances as tight as ±0.001" - that's thinner than a human hair! This level of precision means your components fit perfectly the first time.

Our CNC machining service delivers 20-30% savings compared to traditional methods. We optimize material usage and machining time to keep your costs down.

Even for huge parts, we deliver on time:

5-7 days for complex prototypes

3-5 days for bulk production orders

From design to finishing, we handle every step:

DFM Analysis: We review your designs to suggest improvements that save money and time

Secondary Services: Welding, coating, assembly, and more

Quality Control: Complete inspection and documentation

Upload your CAD files for review

Our engineers suggest improvements

Clear pricing with no hidden fees

Your part moves to our large machine shop

Every part inspected for perfect accuracy

Ready to bring your biggest ideas to life? Istar Machining is ready to help:

Contact us today to discuss your large CNC machining needs!

Large CNC machining means using computer-controlled machines to cut, shape, and finish very big parts. This isn’t your standard machining – we’re talking about parts that can weigh up to 80 tons and measure over 10 meters in length!

We can handle parts up to 10+ meters long and weighing up to 80 tons. For specific requirements, please contact us directly.

Typical lead times are 15-20 days for prototypes and 30-45 days for production runs, depending on complexity and quantity.

Yes! We regularly work with titanium, Inconel®, duplex stainless steel, and many other challenging materials.

Absolutely. Our engineering team provides complete DFM (Design for Manufacturing) analysis to optimize your designs.

We work with aerospace, energy, oil & gas, mining, construction, defense, marine, and many other sectors that need large-scale precision components.

We’re ISO 9001:2015 certified, AS9100 compliant for aerospace, and ITAR registered for defense projects.

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or

1. First, see where the money really goes Most cost discussions stay fuzzy. That’s not useful when you’re trying to

1. The hourly rate gap isn’t random Look at quotes from different CNC shops and you’ll see roughly the same