Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Do you want to know how a laser can cut shapes with very fine detail? A laser cutter is a strong tool that can make your computer designs into real things. It uses a very focused light beam to cut or engrave materials in a very exact way. This article is your guide to help you start. We will explain the laser cutting basics in words that are simple and easy to understand. You will find out how a laser cutter works, what you need to begin, and how to create your first great laser cut project. Reading this will help you save time and stay away from mistakes that people often make.

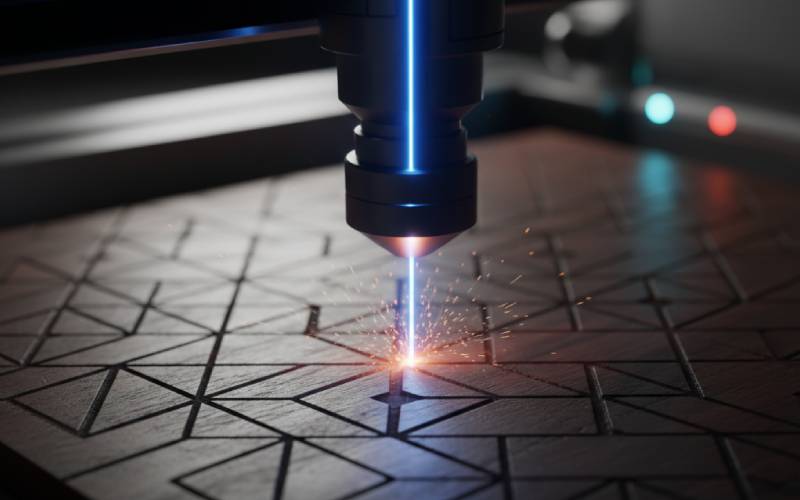

Laser cutting is a method for cutting things using a really powerful beam of light. You can think of it like a very exact and strong magnifying glass that uses the sun. But it is controlled a lot more. A laser cutter is a computer controlled machine. It uses a laser beam to do the work. The machine follows a design from a computer to make cuts that are very exact. This process is used a lot to make all kinds of things, from jewelry and signs to parts for machines. The laser is so exact it can make shapes that are very detailed.

The way a laser cutter works is pretty easy to understand. First, you make a design using a computer. After that, you send the design to the laser cutter. The machine’s laser head moves above the material. This material is called the workpiece. The computer tells the laser when it should turn on and off. When the laser fires, a strong laser beam is pointed through a lens. This lens makes the laser light focus on a very small spot on the surface of the material. The lot of heat from the laser melts, burns, or turns the material into gas. This makes a cut or an engrave. A flow of gas helps blow away the extra material. This leaves a nice, clean edge. The whole job of cutting is quick and very exact. This is the main idea of how a laser makes a great laser cut.

There are a few different types of laser cutters. The two you will see most often are CO2 lasers and fiber lasers. The biggest difference between them is the type of laser source they have. This changes the types of materials they can cut well. Knowing about the different laser types helps you pick the best tool for your project. A CO2 laser is the one most often used by people who do it for fun and by small shops.

CO2 lasers are very good for cutting and engraving many different kinds of materials. This list includes natural materials like wood, paper, leather, and acrylic. A co2 laser cutter works when electricity is sent through a tube filled with a mix of gas, including CO2. This action makes the laser light. Fiber lasers are different. They are a lot better for cutting and putting marks on metals. They use a special kind of technology that creates a laser beam with a smaller focal point and a new wavelength. This makes them stronger for shiny materials like metal. A strong CO2 laser can engrave on some metals. But a fiber laser is the tool you need to cut them in a clean way.

Here is a simple table to show the difference:

| Laser Type | Best For | Common Materials |

|---|---|---|

| CO2 Laser | Cutting & Engraving Non-Metals | Wood, Acrylic, Paper, Leather, Glass |

| Fiber Laser | Cutting & Marking Metals | Steel, Aluminum, Brass, Titanium |

A laser cutter is a smart machine, but it cannot know what you are thinking. It needs instructions to follow. These instructions are in a special kind of file called a vector file. You make these files with design software or graphic design software. A vector file is not like a normal picture, like a JPG file. Normal pictures are made from little dots. A vector file is made from lines, curves, and points that are based on math. The shape is defined by a line, not by a lot of dots.

This is a very important point because the laser cutter has to know where to cut. It follows the lines in a vector file in a perfect way. This is known as a vector path. When you want the laser to cut all the way through a material to make a shape, you have to give it a vector file. The laser will follow the lines in your design exactly. You can think of it like drawing a shape with a pen. The laser follows the line that you drew. This is the only kind of format that the laser cutter can understand for making very exact cuts. You should make your vector graphics with the smallest possible line size so the machine knows it is a line to cut.

We know that a vector file is used to tell the laser where it should cut. But what if you don’t want to make a cut that goes all the way through? What if you would rather engrave a picture or a design onto the surface of the workpiece? For this job, you use raster engraving. A raster file is just a regular picture file, like a photograph. It is made up of dots. When you send a raster file to the laser cutter, it does its job in a different way.

The laser does not follow a line. Instead, it moves from side to side, one line at a time. It works a lot like your everyday inkjet printer. The laser pulses on and off very fast. It burns a very small dot for every dot in the picture. The dark spots in the picture tell the laser to use more power. This makes a mark that is deeper or darker. The light spots use lower power, or sometimes no power at all. This is called raster engraving. You can use grayscale pictures to make very detailed engravings with shading. Engraving with a laser is an excellent way to add details. So, vector is for cutting the outline of shapes, and raster is for filling in shapes or making pictures.

| Task | File Type | How the Laser Works |

|---|---|---|

| Cutting a Shape | Vector | Follows a solid line to cut all the way through. |

| Engrave a Photo | Raster | Moves line by line, firing the laser for each dot. |

When you cut wood with a saw, the blade takes away a little bit of the wood. This makes a small gap. That gap is called the kerf. A laser cutter does the very same thing. The laser beam is not super, super thin; it does have a small size. As the laser burns through the material, it gets rid of a very small piece of it. The size of the gap made by the laser is the kerf. The kerf of a laser cutter is very tiny, but it is a very important detail.

Why is kerf so important? If you are making pieces that you need to join together, like in a puzzle or a box, you have to remember the kerf. For instance, if you laser cut a square that is 1-inch wide from some wood, the hole will be a little bit bigger than 1 inch. The square piece you cut out will be a little bit smaller than 1 inch. This happens because of the kerf. A helpful rule of thumb is to find out the size of your laser cutter’s kerf. When you know the kerf, you can change your design in your design software. This will make sure your cut parts fit together just right. If you forget about kerf, your parts might not fit tightly. The kerf can change based on the material, how thick it is, and the power of the laser.

One of the greatest things about using a laser is that so many materials can be cut or engraved. The material you pick depends on which laser you are using. For most projects, this will be a CO2 laser. The laser is capable of cutting so many materials. You can laser cut items you have at home, or you can buy them from stores that sell them.

Here is a list of popular materials for a laser cutter:

It is also very important for you to know what materials you should NOT cut. Some materials, like PVC plastic, will release toxic gases when the laser burns them. Other flammable materials can be a danger of fire. You should always find out if a material is safe before you want to laser cut it.

The material thickness is a very important setting that you must consider. A very thin sheet of paper only needs a small amount of power from the laser to be cut. A thick slice of wood needs much higher power and must be cut at a slower speed. Your goal is to give the laser beam enough time and power to get all the way through the material. If you set the power too low, or if the speed is too fast, the laser may not cut all the way through.

When you try a new material, you will have to run a few tests to discover the right settings. A good method is to make a small test file that uses different power and speed settings. This will assist you in finding the best mix for the cutting material. For a thicker material, the laser must work with more power. This also can mean the kerf will be a bit wider. You may also see a small slant on the cut edge. This is because the laser beam has the shape of a cone. The top and bottom of the cut can have a slightly different kerf. Finding the correct settings is a big part of the laser cutting basics.

When the laser is cutting, it is really just burning a very thin line. This action makes smoke and little pieces of material. To achieve a very good, clean laser cut, the laser cutter uses a flow of gas. This is known as an assist gas. The gas is pushed out from the nozzle, which is right beside the laser beam. It performs two jobs that are very important during the cutting process.

The first job for the assist gas is to move the melted material or gas out of the way of the kerf. This helps the laser to continue cutting in a clean way. Without the gas, the material could melt and then stick back together after the laser passes. The second job is to prevent burn marks and stop fires. For materials like wood or acrylic, the gas (which is often just air) blows out any small flame that the laser makes. This results in a cleaner edge on your cut pieces. For certain materials, special types of gas like nitrogen are used to get an even better cut quality.

A laser cutter is a strong tool. Like all tools, it should be used carefully and safely. The laser beam itself is very harmful. You should not ever look right at it. All cutting machines of this type have a safe cover that has special glass to keep your eyes safe. You should always make sure the cover is down when the laser is turned on.

Good airflow is also very important. The laser burns material, and this makes smoke and fumes. Some of the smoke can be bad for you or create toxic gases. Your laser machine needs to be hooked up to a system that can pull the air out. This system takes the smoke outside in a safe way. Last, you should never walk away from the laser cutter while it is on. The laser makes a lot of heat, and there is always a small chance of a fire. This is especially true with flammable materials. If you stay with the machine, you can turn it off fast if a problem happens. Being safe is the most important part of using a laser.

You now know the main ideas of how a laser can be used for cutting and for engraving. You know about the different type of laser, why vector files are needed, and the meaning of kerf. To learn more, the best thing to do is practice. If you are able to use a laser cutter, you should begin with easy projects. You can try to cut simple shapes out of cardboard or a thin piece of plywood.

Try different settings for the power and speed to see how they make the laser cut different. You can learn to use graphic design software to make your very own vector designs. You can find many helpful videos and lessons online that can show you more difficult skills. It is good to remember that laser cutting is a lot like other CNC machines or even 3D printers. All of them begin with a computer file and change it into a real object. The more times you use a laser, the more sure about what you are doing you will feel.