Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

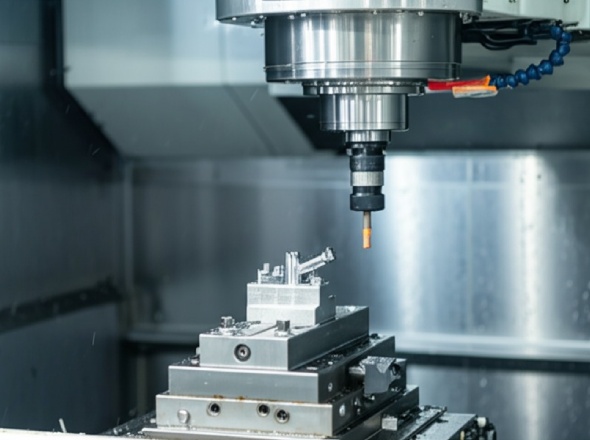

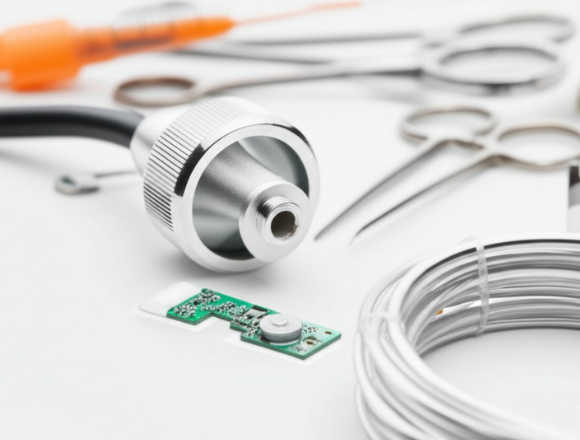

At Istar Machining, we make medical parts that doctors and hospitals count on. From tiny surgical tools to implants that go in your body, our machines cut metal and plastic with amazing accuracy. Let’s see how our medical CNC machining can help your next project!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Medical CNC machining uses computer-controlled tools to make parts for the medical field. These special machines follow exact instructions to cut, shape, and polish materials with micron-level precision. This means parts that fit perfectly in the human body or tools that work exactly as doctors need them to.

Medical parts must be:

What We Make | How We Make It | Why It Matters |

Orthopedic implants (knee/hip) | 5-Axis CNC Machining with ±0.001 mm tolerance | Perfect fit means less pain and faster healing |

Surgical robotics parts | Complex geometry machining | Helps doctors perform super precise operations |

Dental implants | Biocompatible materials like ASTM F136 titanium | Safe for your mouth and lasts many years |

Micro-scale parts for catheters | Swiss-Type Machining | Ultra-thin, perfect tubes that go through blood vessels |

Custom surgical tools | Cleanroom Machining | Tools ready for immediate use in surgery |

Patient-specific guides | Rapid Prototyping (3-5 days) | Custom parts that match exactly to your body |

Implant surfaces | Electropolishing | Super smooth surfaces that prevent infections |

CNC machining offers precision and versatility for a wide range of medical-grade materials. Choosing the right material is critical for performance, safety, and compliance. Here are common materials we work with for medical applications:

Metals

Stainless Steel (Common Medical Grades: 316L, 304L, 17-4 PH, 420, 440C)

Description: Highly resistant to corrosion and staining, durable, and easily sterilized. Medical grades (like 316L) offer excellent biocompatibility. Different grades provide varying levels of strength, hardness, and corrosion resistance.

Good for:

Why customers love it: “Its proven biocompatibility (esp. 316L), excellent corrosion resistance, sterilizability, and balance of strength and cost make it a reliable standard for many non-implant and implantable medical devices.”

Titanium (Common Medical Grades: Grade 5 – Ti-6Al-4V, Grade 2 – Commercially Pure)

Description: Exceptional biocompatibility, superior strength-to-weight ratio, highly resistant to corrosion (especially body fluids), and non-magnetic (MRI compatible). Can be challenging to machine.

Good for:

Why customers love it: “Unmatched biocompatibility for long-term implantation, high strength with low weight reduces patient load, and excellent corrosion resistance ensures device longevity and patient safety. MRI compatibility is a significant advantage.”

Cobalt-Chrome Alloys (CoCr, e.g., CoCrMo)

Description: Known for very high strength, hardness, excellent wear resistance, and good biocompatibility and corrosion resistance. More difficult to machine than Titanium or Stainless Steel.

Good for:

Why customers love it: “Its exceptional wear resistance and strength make it ideal for demanding, long-lasting implant applications like artificial joints, ensuring durability and performance over time.”

Aluminum (Common Grades: 6061, 7075)

Description: Lightweight, good machinability, excellent thermal and electrical conductivity, and cost-effective. Can be anodized for improved corrosion resistance and color-coding. Generally not used for implants due to lower biocompatibility compared to Ti or SS.

Good for:

Why customers love it: “It offers a great combination of low weight, ease of machining, and cost-effectiveness for non-implantable components, equipment housings, and prototyping needs.”

Plastics

Description: High-performance thermoplastic with excellent mechanical strength, stiffness, chemical resistance, and biocompatibility (implantable grades available). Withstands multiple sterilization cycles (steam, EtO, gamma). Radiolucent (doesn’t obstruct X-rays).

Good for:

Why customers love it: “Offers metal-like strength with excellent biocompatibility and radiolucency, making it a top choice for implants where imaging is needed. Its sterilizability and chemical resistance are also key benefits.”

Description: High-performance thermoplastic offering excellent toughness, impact strength, and high heat resistance. Withstands repeated steam sterilization cycles exceptionally well. Good chemical resistance and available in transparent/opaque biocompatible grades.

Good for:

Why customers love it: “Its ability to withstand numerous autoclave cycles without degradation, combined with its toughness and biocompatibility, makes it perfect for reusable surgical instruments and trays.”

Description: High-strength amorphous thermoplastic with high heat resistance, good chemical resistance, and dimensional stability. Biocompatible grades available. Withstands multiple sterilization methods (steam, EtO, gamma). Often amber/transparent.

Good for:

Why customers love it: “Provides high strength, stiffness, and excellent resistance to repeated sterilization, often at a slightly lower cost than PEEK for applications not requiring PEEK’s specific mechanical properties.”

Description: Strong, highly impact-resistant, and transparent thermoplastic. Good dimensional stability. Medical grades offer biocompatibility. Sterilizable via EtO and gamma radiation; limited autoclave resistance.

Good for:

Why customers love it: “Its transparency, high impact strength, and cost-effectiveness make it ideal for housings, visors, and many single-use devices where clarity and toughness are important.”

Description: Strong, stiff thermoplastic with low friction, excellent dimensional stability, and good machinability. Medical grades offer biocompatibility for specific applications (often surface contact, not implants). Good resistance to cleaning agents.

Good for:

Why customers love it: “Excellent machinability, stiffness, and low friction make it great for precise, functional parts in devices and instruments where long-term implantation isn’t required.”

Description: Extremely high abrasion resistance, very low coefficient of friction, high impact strength, and good biocompatibility. Often supplied as semi-finished shapes (rods, sheets) for machining.

Good for:

Why customers love it: “Its unparalleled wear resistance and low friction are critical for the longevity and success of artificial joints, providing smooth articulation for decades.”

Our machines can cut parts as small as 0.5mm with perfect accuracy. This makes tiny parts for things like hearing aids or dental tools. Our precision CNC machining service ensures every part meets exact specifications.

Medical parts need to be super clean. We make sure no dust or germs get on your parts during manufacturing.

We can make surfaces:

We check every part with special tools to make sure:

Our parts help in many medical areas:

We follow all the strict rules for medical manufacturing

Get parts in 3-5 days when needed urgently

We know which metals and plastics work best in the body

Our parts don't fail when lives depend on them

No contamination in our manufacturing process

We look at your designs and suggest improvements

We make test pieces to try out

We help make sure everything works right

We make your finished parts exactly to spec

We provide all paperwork needed for medical approval

In medical work, quality isn’t just about looking good—it’s about saving lives. Our automated inspection systems check every part with computer precision. We use special Renishaw probes to measure parts down to 0.001mm—thinner than a human hair!

Whether you need surgical instruments, implants, or medical device components, our medical micro machining capabilities deliver the precision your patients deserve.

Contact Istar Machining today to discuss your medical CNC machining needs. We’re ready to help make parts that improve and save lives!

A: Yes! We work with FDA-approved materials that are safe for implants.

A: We offer rapid prototyping in 3-5 days and can set up regular production schedules.

A: Absolutely. Our engineers can review your designs and suggest improvements for better manufacturing.

A: We maintain ISO 13485, ISO 9001, and follow FDA 21 CFR Part 820 requirements.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or