Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Metal 3D printing technology is changing the way we make things, from jet engine parts to medical parts for the body. If you have ever wondered how you can print a solid metal object, this is the right place for you. In this article, I’ll give you a simple look at this very modern technology and explain how it works.

When people hear about “3D printing,” they often think of small plastic toys. But metal 3D printing is something totally different. It’s a way of doing additive manufacturing. Think of it like this: older ways of making metal parts are often called “subtractive.” You start with a big block of metal. Then you cut or drill away the metal you don’t need. This can make a lot of wasted metal.

Additive manufacturing works the other way around. It builds a part from the bottom up, one tiny layer at a time. The machine reads a digital design file. This file is like a map for the printer. The machine adds layers of metal powder just where they need to be. It then uses heat or another method to stick that powder together. This happens again and again, maybe hundreds or thousands of times. At the end, you have a strong, solid metal object. This technology lets us manufacture parts that are difficult to make in any other way.

This 3d printing technology is a big step forward. It is not just for making quick models (rapid prototyping) anymore. It is now used to manufacture finished, very strong metal parts for the aerospace industry and many other fields. The capability of this technology to make tricky metal shapes is really amazing.

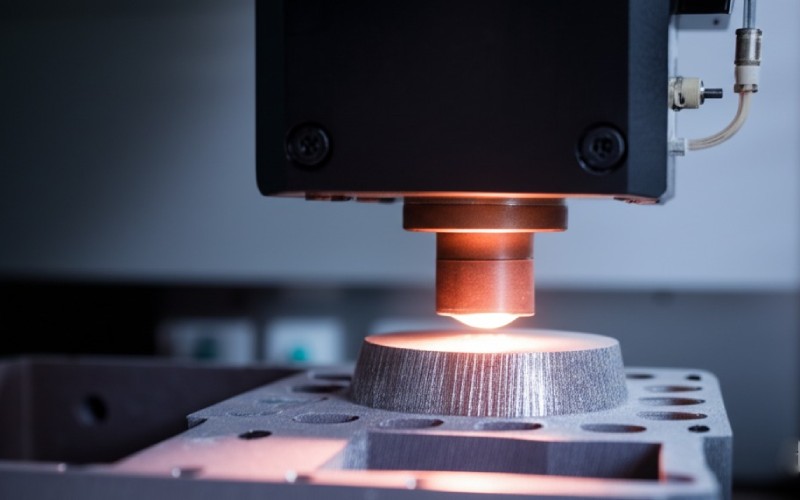

One of the most popular ways to do metal 3d printing is called Powder Bed Fusion. Let me explain how this cool technology works. Inside the machine, there is a flat plate inside a sealed box or chamber. This chamber is often filled with a special inert gas. This gas stops the hot metal from mixing with the air. To start making a metal part, the machine spreads a very thin, flat layer of metal powder on the plate.

Next, a strong laser or an electron beam points at the powder. It moves very, very carefully. It follows the design from a CAD file. Wherever the beam touches the powder, it gets so hot that the little bits of metal powder (metal powder particles) melt and stick together. This makes one solid layer of the metal part.

Once a layer is finished, the plate moves down just a little bit. A new layer of metal powder is then spread on top. This whole cycle happens again and again. The laser melts the new powder. It also sticks it to the layer underneath. This is how 3d printers produce parts, layer by layer. This manufacturing process continues until the whole metal part is built. This amazing technology can manufacture a very strong metal part.

You will often hear two names used with powder bed fusion: DMLS and SLM. DMLS stands for Direct Metal Laser Sintering. SLM stands for Selective Laser Melting. They sound a lot alike. Many people who work with this technology use both names for the same thing. I used to be confused by this, too. But they are a little bit different in how they work.

With SLM technology, the name tells you what it does. It fully melts the metal powder. For a second, the metal becomes a liquid. Then it cools down and gets hard. This makes a very solid and strong part. On the other hand, DMLS heats the metal powder up. The bits of powder stick together very tightly, but they do not fully melt into a liquid. Think of it like pressing snowflakes together to make a hard snowball. Companies like EOS were the first to create the DMLS technology.

In the end, both DMLS and SLM are great additive manufacturing technologies. They both make very strong and reliable metal parts from metal powder. Both DMLS and SLM are part of the powder bed fusion family. Today, many new DMLS machines also fully melt the metal, so it’s hard to see the difference. The important thing to know is that both DMLS and SLM use a laser to build metal parts layer by layer. SLM is a very important technology in the metal printing world.

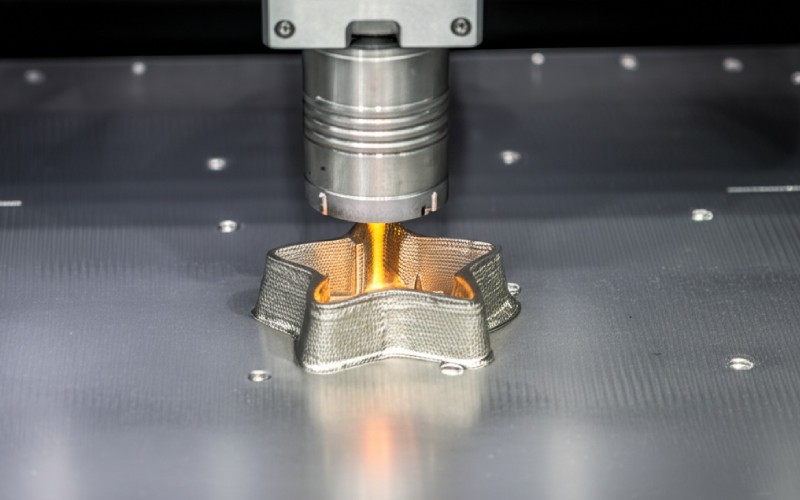

DMLS and SLM are popular, but there is another key way to do metal additive manufacturing. It is called Binder Jetting. This technology works in a very different way. Instead of using a laser to melt metal powder, binder jetting uses a liquid binding agent. This agent is like a special glue. The machine works a bit like a paper inkjet printer.

A special printer part moves over the metal powder. It carefully drops little bits of the binder liquid where they are needed. This jet of binder makes the metal powder particles stick together. This creates one layer of the part. The build plate then moves down, a new layer of metal powder is put on top, and the process happens again. This part of the manufacturing process is often much faster than DMLS or SLM.

After the printing is done, the part is called a “green” part. It is not very strong yet. You can think of it like a sandcastle. It needs another step to make it a strong metal part. The part is taken out of the extra metal powder. Then it is put into a very hot oven, called a furnace. Inside the furnace, the binder glue burns away. The metal bits then stick (fuse) together to make a solid, dense part. This technology is great for making many metal parts at once. Material jetting is a technology that is a lot like this one. It also uses a jet to put down material.

One of the great things about this printing technology is the many different materials you can use. You are not stuck with just one type of metal. Many different metal powders are ready to use. Each one has its own special features (characteristic) and strengths (mechanical properties). This lets an engineer pick the perfect metal for the job.

Here are some of the most common metals used in metal 3d printing:

| Metal Type | Common Uses | Key Feature |

|---|---|---|

| Stainless Steel | Tools, kitchen items | Strong, does not rust |

| Titanium Alloy | Aerospace parts, medical parts | Very strong and very light |

| Aluminum Alloy | Car parts, light brackets | Light, moves heat well |

| Inconel (Nickel Alloy) | Jet engines, hot jobs | Stays strong when very hot |

| Cobalt-Chrome Alloy | Teeth crowns, body parts | Very hard, does not wear out |

The metal powder itself is amazing. It is made of very small, perfectly round balls. Because of their shape, the powder can spread out very evenly inside the machine. This is very important for making good metal parts. Picking the right alloy is a very important step in the additive manufacturing process. This makes sure the final part has the right kind of strength and features. Using metal like this makes so many new things possible.

When I first learned about 3d metal printing, I used to wonder why some parts came out of the machine with a metal frame around them. These are called support structures, and they are very important. Metal 3d printing builds parts from the bottom up. If a design has a piece that sticks out, like a roof, it needs something to sit on while it is being printed.

If there were no support structures, these pieces that stick out would bend or fall down into the loose metal powder. The supports work like a base. They hold the shape (geometry) of the part steady during the printing job. Support structures are also very important for another reason, which is heat. The laser creates a lot of heat. This heat can make the metal bend out of shape. It is like how wood can bend when it gets wet. Support structures help hold the part down to the build plate. They also help pull heat away from the part. This helps keep the metal from bending.

These supports are designed in the CAD software at the same time as the part itself. After the printing is finished, the support structures must be taken off carefully. This is an important step in the finishing of the metal part. An engineer will try to improve (optimize) a design so it needs fewer support structures.

A metal part is almost never ready to be used as soon as it comes out of the metal 3d printer. It almost always needs some finishing work. These steps are called post-processing methods. They are very important to make sure the part has the correct size (dimensional accuracy) and a smooth feel. The first step is usually taking the part off the build plate and getting rid of the support structures.

After the support structures are taken off, the part often needs to be treated with heat. This can mean heating the metal part in a furnace. This process is called annealing. This process gets rid of the stress inside the metal that was created during printing. It also makes the metal’s strength better and helps it last longer. This is a very important step to make sure the part has good mechanical properties.

Last, the surface of the metal part may need to be made smooth. Because the part is built in layers, it can feel a little rough. This is called surface roughness. Steps like machining, polishing, or tumbling can be used to make a smooth, finished surface. These various post-processing steps add to the total cost and take more time. But they are needed to make a really good final part. This is one of the limitations of metal printing.

This is where metal additive manufacturing is really great. With older ways of manufacturing, an engineer has to follow a lot of rules. For example, you can only drill straight holes. You also can’t make tricky shapes on the inside of a part very easily. But with 3d metal printing, the rules change. This technology gives us a lot of freedom in how we design things (design flexibility). An engineer can use CAD (Computer-Aided Design) software to make parts with complex shapes. These shapes were impossible to make before.

For instance, you can design parts that have little tunnels inside them (internal channels) to help with cooling. You can also create lightweight parts by using a special structure on the inside called a lattice. A lattice is like a honeycomb inside the part. It makes the part very strong but uses much less metal. This saves weight and material. This kind of improvement (optimization) is perfect for the aerospace industry. In that business, even a tiny bit of weight matters a lot.

This capability to manufacture parts with very tricky shapes (complexity) changes everything. It lets us make things like special medical parts that fit a person’s body perfectly or very good fuel nozzles for jet engines. This is a powerful tool for any engineer.

I have seen how this technology can completely change the way things are made. The good things about it are much more than just making cool shapes. Metal additive manufacturing has real benefits. These benefits can help make better products and save a lot of money (savings). It is a very strong and reliable (robust) technology.

Here are some of the biggest benefits:

Like any technology, metal 3d printing is not perfect. It is important to know its downsides to know when it’s the right choice. I always tell people it is a great tool. But it is not the right answer for every job. This technology has a few challenges.

One of the biggest problems is the cost. Metal printers from companies like 3D Systems or EOS are expensive. The special metal powder costs a lot, too. This means the manufacturing costs for making each part can be high. This is especially true if you need to make a large number of parts (part volume). It is often not the best choice for making thousands of simple metal parts.

The size of the parts you can make is also limited. You can only make parts that fit inside the machine’s build chamber. You can’t print a car door in one piece, for example. The process can also take more time than traditional manufacturing methods like molding, especially when you are making many parts at once. Last, the need for finishing work adds more time and work. There is also a small chance of problems like porosity, which means tiny holes in the metal. This can happen if the printing process is not controlled very well. These are the main limitations of metal additive manufacturing technology.

Metal 3D printing is a strong technology that is changing the way we manufacture things. It is not just for making test models anymore. It is now used to make strong, finished metal parts for tough jobs in industrial applications.

Here are the most important things to remember: