Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Multi Jet Fusion from HP is very quick and makes very strong parts. If you have to create a tough prototype or even parts that are ready to be used, MJF could be just what you need. This article is my easy-to-read guide to multi jet fusion. I will tell you how it works, the best ways to use it, and how it can help with your own work. This guide is helpful for people who are new to this and for people who already know a lot.

Let’s begin with the simple facts. Multi Jet Fusion is a kind of 3D printing process. It was developed by HP (Hewlett-Packard). You probably know that company because they make paper printers. You can think of MJF like a much newer and better type of that. It uses a powder made of very small bits, often a kind of nylon, to create parts one layer by layer. This is a powder bed fusion technology. That just means it makes the parts inside a box full of powder. This is a new technology that is making a big difference in the way things are made.

So, why is MJF important to you? Because it is really, really fast and the parts it creates are very tough. I have used MJF to create parts that had to twist, connect, and handle rough use. They work well for a long time. The MJF technology is excellent. You can make functional parts that actually work, not just pieces you put on a shelf. This unique 3d printing way of doing things is perfect for creating lots of parts at the same time. The speed and the high quality of MJF make it one of the best options for my 3d printing projects. It is a very useful tool.

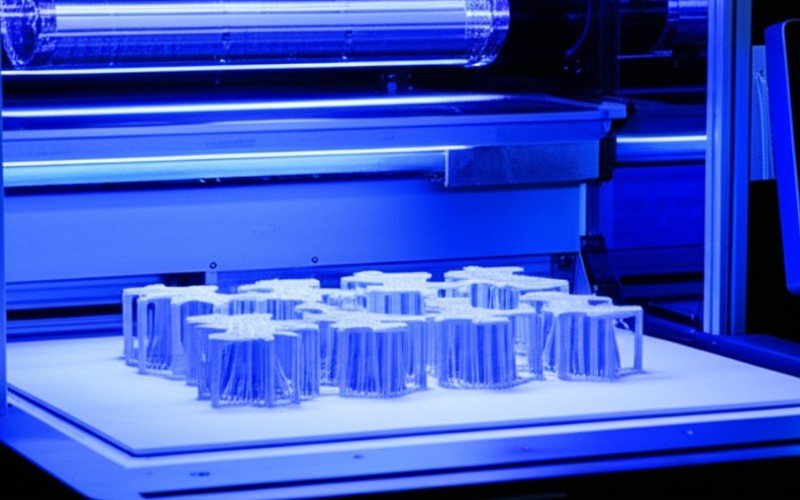

To me, the MJF 3d printing process is very interesting. It feels like I am watching magic. Here is how the printer does it. First, a very thin layer of powder is pushed across a flat building area. A part called a material recoater carriage does this. Next, a special part called the printing and fusing carriage moves across the build area. It does two important jobs at once. It sprays a special liquid called a fusing agent. This goes where the part needs to be solid. It also sprays another liquid called a detailing agent. This goes around the edges to make the detail very clear.

After these liquids are put onto the powder bed, strong heating lamps go over the top. The spots that have the fusing agent on them soak up the heat. This makes the powder fuse, or melt together, to become a solid layer. The detailing agent helps make sure the edges are clean and sharp. The unfused powder that is all around the part just stays as a loose powder. The build platform then moves down a tiny bit. A next layer of material is added, and it all happens again. This layer by layer method is used over and over until the part is done. The 3d printing process happens completely inside the printer.

I am often asked how MJF is different from other 3d printing technologies. Let’s look at Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM). SLS is the most like MJF. They both use a powder bed. The main difference is the way they fuse the powder. SLS printers use a powerful laser to melt the powder. The laser has to draw the shape of the part, bit by bit. With an MJF printer from HP, a fusing agent is used with a heating lamp that warms the whole area in one go. This is why MJF is faster than SLS. Both MJF and SLS are two technologies that make very strong parts.

FDM is the type of 3D printing that many people use at home. An FDM printer works by melting a roll of plastic string and building a part one line at a time. FDM is good for making a quick and simple prototype. But the parts are not as strong as MJF parts. They have lines between each layer that can be weak spots. An MJF part is strong in all directions. This is called being isotropic. The MJF process fuses the powder so well that the layers mix together perfectly. I often use FDM for very simple models, but I choose MJF for parts that have to do a job.

Here is a simple table to show how they are different:

| Feature | MJF (Multi Jet Fusion) | SLS (Selective Laser Sintering) | FDM (Fused Deposition Modeling) |

|---|---|---|---|

| How it Works | Uses fusing liquid and heat | A laser melts the powder | Melts and places a plastic string |

| Speed | Very Quick | Quick | Slow |

| Part Strength | Very Strong (Isotropic) | Strong | Just Okay (Weak between layers) |

| How it Looks | A little rough, but the same all over | A little rough | You can see the layer lines |

| Best For | Functional prototypes, final parts | Strong prototype models | Fun projects, simple models |

From my point of view, the best thing about MJF 3D printing is how fast it is. You can print production runs in a very short amount of time. Because the printer can fuse a full layer in one pass, it builds parts much more quickly than an SLS printer. This is a big deal because you can get your parts sooner and test your ideas faster. This is very important when you need to make a prototype without waiting. MJF is a great kind of additive manufacturing technology.

Another great thing is the quality of the parts. MJF parts have very good detail and a surface finish that looks the same all over. The parts are also very tough and last a long time. I have made functional parts with MJF that took the place of parts that used to be made of metal. Because the unfused powder holds up the part while it is being built, you don’t have to add extra support pieces. This eliminates the need to do a lot of cleanup work later. You can design very complex parts with MJF that are not easy to make in other ways. The MJF technology is ideal for functional prototypes.

When I began using MJF, there were not many materials to choose from. Today, the number of materials available is getting bigger. The material people use most for Multi Jet Fusion printing is Nylon 12, which is also called PA12. This is a great material that can be used for many things. It is strong, a bit bendy, and does not get damaged by chemicals. I use PA12 for most of my MJF work. It is perfect for making things like a housing or an enclosure.

Besides PA12, there are other useful 3d printing materials. PA11 is another kind of nylon. It is more bendy and is better at taking hits without breaking than PA12. It is a good choice for parts that need to bend a lot. There is also TPU, which feels like rubber. I have used TPU to make soft handles and flexible gaskets. You can also use materials like PP (polypropylene). HP and other companies are always creating new multi jet fusion materials. The right material for you depends on what you need your printed part to do.

When your part is finished by the MJF printer, it is not quite ready to use. It is stuck inside a block of loose unfused powder. This is where post-processing happens. Post-processing is all the steps you do to clean and finish the part. First, the whole block of powder with the parts inside is moved to a processing station. This lets the parts cool down nice and slow. If they cool too quickly, they might bend or twist out of shape.

After the parts are cool, you need to vacuum the unfused powder. The great thing is that this extra powder can be used again for the next job, which saves money and is good for the earth. After most of the powder is gone, you will often use a machine for bead blasting. This machine shoots tiny, gentle beads at the part. It helps to clean it and remove any remaining powder. This gives the printed with MJF part a good surface finish. Sometimes, parts are colored black to make them look more finished. Post-processing is a very important step to get a great MJF part. Good post-processing makes a huge difference.

No technology is perfect, and MJF has a few things to think about. I want to be open with you so you know what you are getting into. The natural color of most MJF parts is a light gray. The surface finish is also a little bit rough, like very fine sandpaper. It is a good surface quality, but it is not completely smooth like a part made by an sl (Stereolithography) printer. If you need a part that is clear, super smooth, or has a bright color, MJF might not be the best choice unless you do extra post-processing like painting. sl is a different method that uses a liquid plastic.

Something else to remember is that the MJF process uses a lot of heat. This means if you have very thin walls or long parts with no support, they can sometimes bend. You need to keep this in mind when you design your parts. But, when you compare it to other powder bed fusion methods, MJF does a very good job of controlling the heat. Even with these small issues, I believe the good things about MJF—like its speed, strength, and great detail—make it a winner most of the time. A smart design for MJF can help you avoid these issues. Other methods like binder jetting have their own problems too.

I have seen MJF uses in so many interesting areas. This technology can be used in lots of different ways. In the automotive world, car makers use MJF to make a prototype for new car parts. They can test a new idea in just a few days instead of many weeks. Because the parts are so strong, they can even be used as final parts in some cars. I have seen 3d printed air vents and special holders printed with MJF. This HP Multi Jet Fusion technology is really useful.

MJF is also wonderful for making special jigs and fixtures. These are tools that are used on an assembly line to hold parts still while people work on them. Using MJF to make these tools is fast and does not cost a lot of money. It helps factories make better things more quickly. I have also used MJF for small production runs of end-use parts. If you only need a few hundred of an item, it is often cheaper to use MJF than to make a big, costly mold. This is a big reason why many companies are excited about Multi Jet Fusion 3D printing. You can make a prototype and the final part with the same machine.

A great 3D printed part always starts with a great design. You make your design in a computer program called CAD (Computer-Aided Design). When you are designing something for MJF, I always follow a few simple rules. First, make sure your walls are not too thin. A good rule is to make them at least 1 millimeter thick. This will make sure your part is strong enough and will not break during post-processing.

Second, if you make your part hollow, don’t forget to add some small holes. These are called escape holes. They let all the trapped unfused powder get out when the part is being cleaned. If you forget them, you will have a part that is full of powder you cannot get out. Also, think about how your parts will connect. For a good assembly, it is a good idea to leave a very small space between parts that need to click together. The Multi Jet Fusion 3D printing process is very exact, but this little bit of extra room helps everything fit together just right. If you follow these tips, you will get wonderful 3d parts from the MJF process.

Let’s say you have a design and you are excited to try MJF 3D printing. The best part is that you do not have to buy your own very expensive HP 3d printers. There are a lot of companies that have an online 3d printing service. I use them often because it is so easy. All you need is your CAD file.

Most of these services have a website where you can put your file. The website will look at your model and tell you the price right away. This is how you get an instant quote. You can pick your material, such as PA12 or TPU, and see how that changes the price. When you are happy with the price, you can order your part. They will print it on their professional 3d printers and send it right to your home. It is a very simple way to use the power of Multi Jet Fusion without needing a lot of money.

Here are the most important points I’ve shared about HP’s Multi Jet Fusion (MJF) technology: