Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

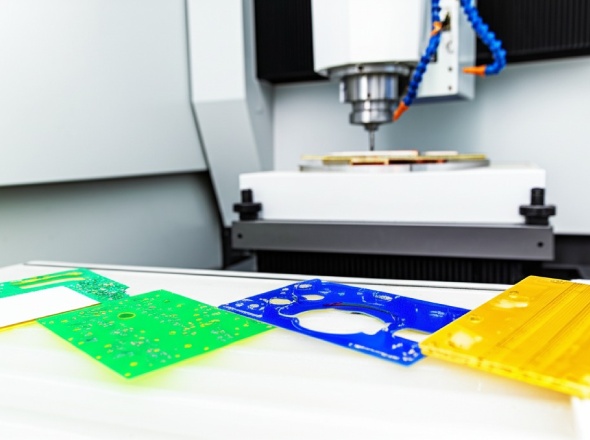

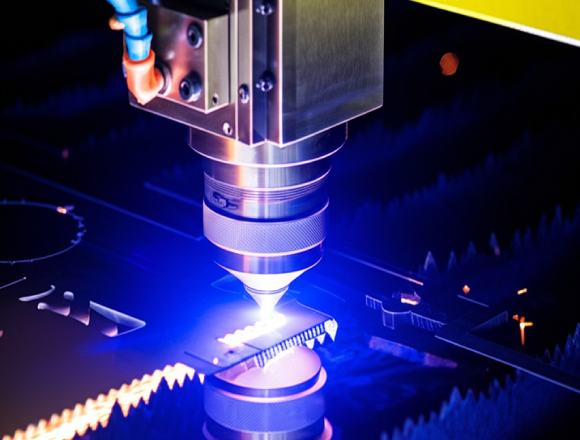

Are you looking for top-quality PCB boards made with exact precision? Our PCB CNC machining service gives you perfect circuit boards for all your projects. Let’s look at what makes our service special!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

PCB CNC machining uses computer-controlled tools to make circuit boards with amazing accuracy. Unlike other methods, CNC machining can work with many materials and create complex designs fast.

Our CNC prototype machining service helps you get your PCB ideas from design to reality quickly.

Our PCB CNC machining creates boards for:

Feature | Details |

Tolerance | ±0.005mm (super accurate!) |

Board Size | Up to 500mm × 600mm |

Layer Count | 1–20 layers |

Spindle Speed | 24,000 RPM for clean cuts |

Tool Types | Carbide end mills (0.2–3mm) |

File Types | Gerber, ODB++, DXF, STEP |

Surface Finishes | ENIG, HASL, Immersion Silver |

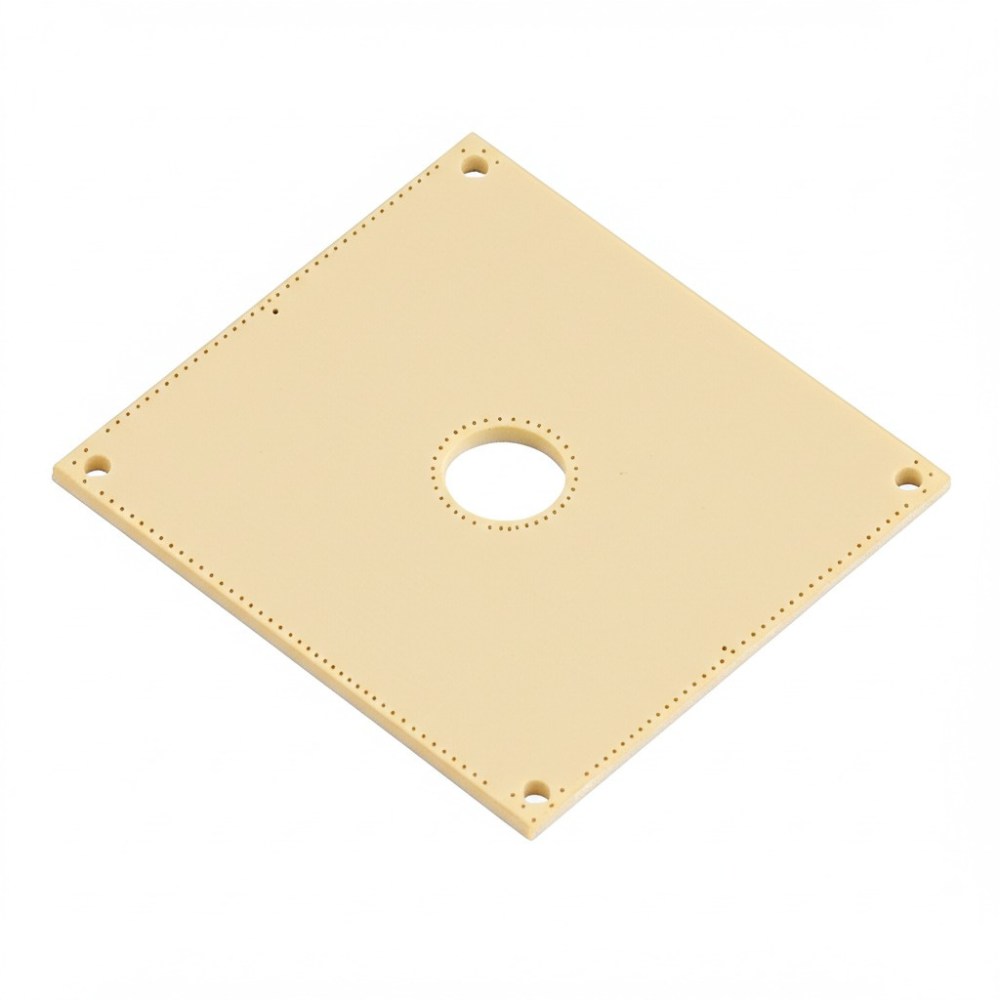

FR4 is the most popular material for PCBs. This material is made of woven glass cloth with epoxy resin.

When to use it: FR4 works great for PCB drilling pads, making FPC stronger, and keeping transformers safe. It’s the go-to choice for most circuit boards because it’s strong and doesn’t cost too much.

This lightweight metal is perfect for PCBs that need to stay cool.

When to use it: Choose aluminum for heat sinks, RF shields, and CNC enclosures. Our 5-axis machining service can shape aluminum with tiny details down to ±0.1mm.

When you need something extremely strong but light, carbon fiber is perfect.

When to use it: Great for drone frames, tools that need to be strong, and parts that get a lot of wear. Carbon fiber also blocks EMI (electromagnetic interference).

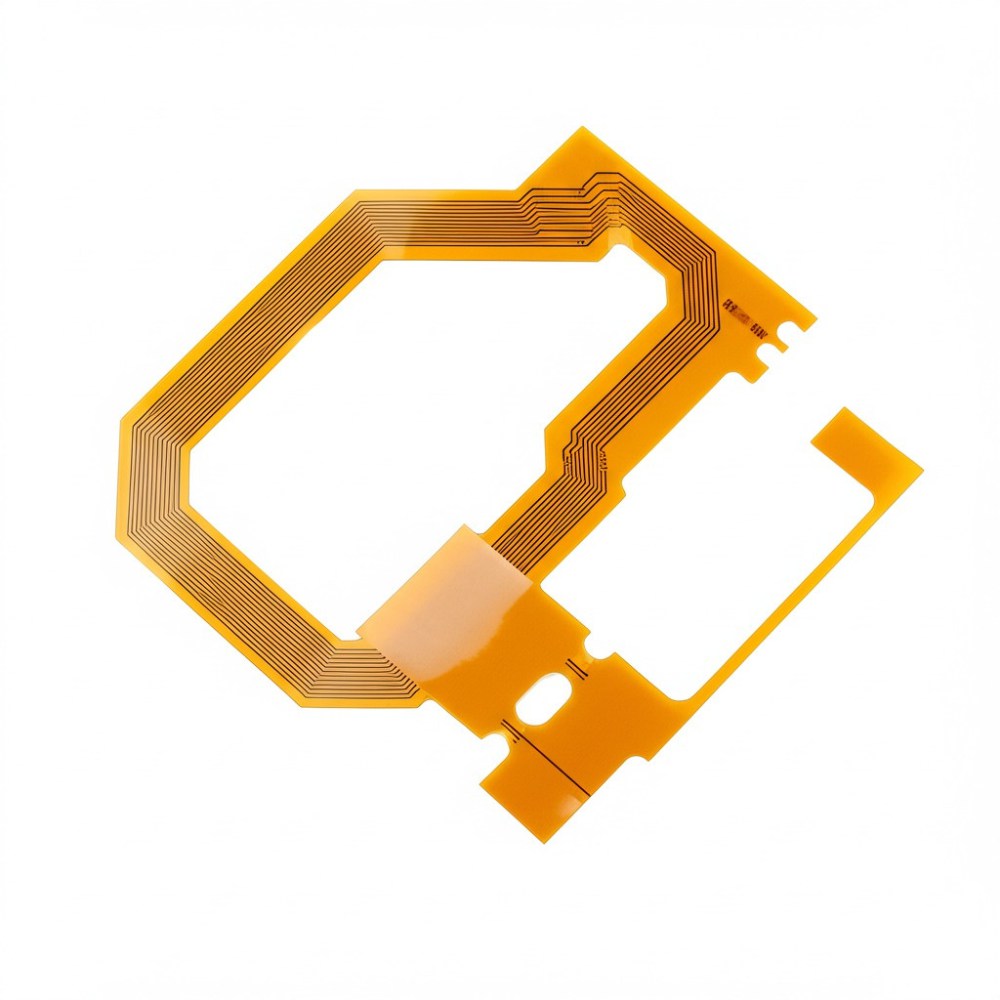

Need something that can bend? Polyimide is the answer.

When to use it: Perfect for flexible PCBs, sensors that work in hot places, and wiring in airplanes. It can be bent many times without breaking.

For high-frequency circuits, Rogers materials are the best choice.

When to use it: Choose Rogers for 5G antennas, microwave circuits, and car radars. Our CNC milling experts can work with these special materials to get the best results.

For PCBs that need to carry lots of power, copper-clad laminates are perfect.

When to use it: Best for power electronics, high-current PCBs, and LED drivers. These materials help make energy-efficient systems for factories and cars.

What You Need | Best Material Choice | Why It’s Good |

Standard PCBs | FR4 Epoxy Glass | Cost-effective, widely used, good electrical properties |

Circuits that run hot | Aluminum 6061 | Pulls heat away, keeps components cooler |

Lightweight projects | Carbon Fiber | Strong but very light, perfect for drones and portable devices |

Bendy circuits | Polyimide Films | Can flex thousands of times without breaking |

High-speed signals | Rogers RO4000® | Less signal loss, better for 5G and wireless |

Power-hungry designs | Copper-Clad Laminate | Handles high current, good heat management |

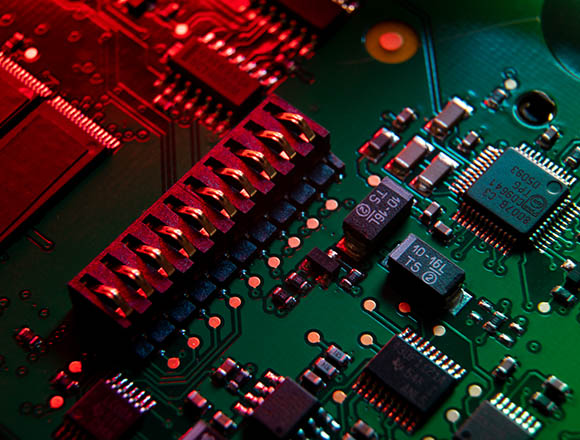

Our PCB CNC machining services help many different industries:

We make high-frequency PCBs for radar and communication systems with burr-free edges that work in tough situations. These boards must be perfect, and our precision CNC machining delivers exactly that.

For tiny medical tools and implants, we make small PCBs with micro-vias. These boards must be safe for use in the body.

Smart devices need small, power-saving PCBs. We make ultra-thin traces (less than 0.1mm) for energy-saving designs.

Car parts face heat, shaking, and wetness. We make strong FR4 boards that can handle these tough conditions.

We build 20-layer HDI boards with special hidden vias to save space in phones and gadgets.

Get test boards in just 5 days!

Our tools work to ±0.005mm precision

We check every board with special tests

Fair costs with no surprise fees

Our team finds and fixes design problems

For hot-running boards, we use copper-filled vias and aluminum cores to move heat away. This makes LED lights last 30% longer!

We can make bendy polyimide boards that can fold over 100,000 times without breaking. Perfect for wearable tech!

For fast data, we use special Rogers 4350B materials and laser-cut microstrip lines to keep signals strong.

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Ready for perfect PCBs? Our team at Istar Machining is ready to help with your next project. We combine CNC milling expertise with PCB knowledge to give you the best results.

Don’t wait for your important PCB projects. Contact us now for a free quote in just one hour!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or