Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for high-quality pipe parts made with cutting-edge technology? Our pipe CNC machining services deliver precise, durable, and custom-made pipe components for many different industries. Let’s explore how we can help you!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

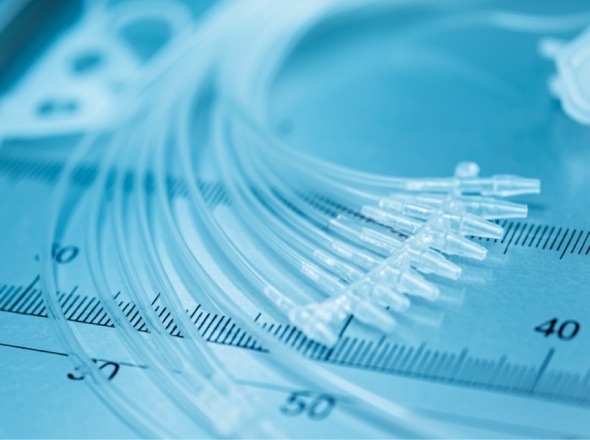

Pipe CNC machining uses computer-controlled machines to cut, shape, and finish pipes with amazing accuracy. Our machines follow digital blueprints to create perfect pipe parts every time.

Selecting the right material is crucial for the performance and longevity of your CNC machined pipes and tubes. Our advanced Pipe CNC Machining capabilities allow us to work with a diverse range of materials to meet your specific project requirements, from fluid handling to structural applications. Here’s a guide to some of the materials we frequently machine:

Metals

Aluminum (Common Grades: 6061, 7075, 5052, 2024) is lightweight, offers good corrosion resistance (especially when anodized), possesses excellent thermal and electrical conductivity, and is highly machinable, allowing for complex features on pipes and tubes.

Good for:

Why customers love it: “It provides an excellent strength-to-weight ratio, good machinability leading to faster production times and lower costs, and natural corrosion resistance suitable for many environments.”

Stainless Steel (Common Grades: 304, 316/316L, 303, 17-4 PH) offers excellent corrosion resistance, high strength and durability, and good high/low-temperature resistance. 316/316L is particularly resistant to chlorides and acids.

Good for:

Why customers love it: “Its superior corrosion resistance ensures longevity in harsh environments and compliance for sanitary applications, combined with high strength and a clean aesthetic finish.”

Carbon Steel (Common Grades: 1018, 1020, 1045, A36) is a cost-effective, strong, and versatile material known for its good machinability and weldability. Often available in various pipe schedules. Requires coating (paint, galvanizing, plating) to prevent rust.

Good for:

Why customers love it: “It’s an economical choice offering good strength and ease of fabrication for a wide range of non-corrosive structural and fluid handling applications.”

Alloy Steel (Common Grades: 4130, 4140, 4340) contains additional alloying elements (like chromium, molybdenum, nickel) enhancing properties like strength, hardness, toughness, and heat resistance compared to carbon steel.

Good for:

Why customers love it: “Provides significantly higher strength and toughness than carbon steel, making it suitable for demanding mechanical applications requiring durability under high stress or load.”

Brass (Common Alloys: C360, C260) is an alloy of copper and zinc, known for its excellent machinability, good corrosion resistance, electrical conductivity, and attractive gold-like appearance.

Good for:

Why customers love it: “It’s one of the easiest metals to machine, reducing costs, while offering good corrosion resistance and an appealing look, especially for fittings and decorative parts.”

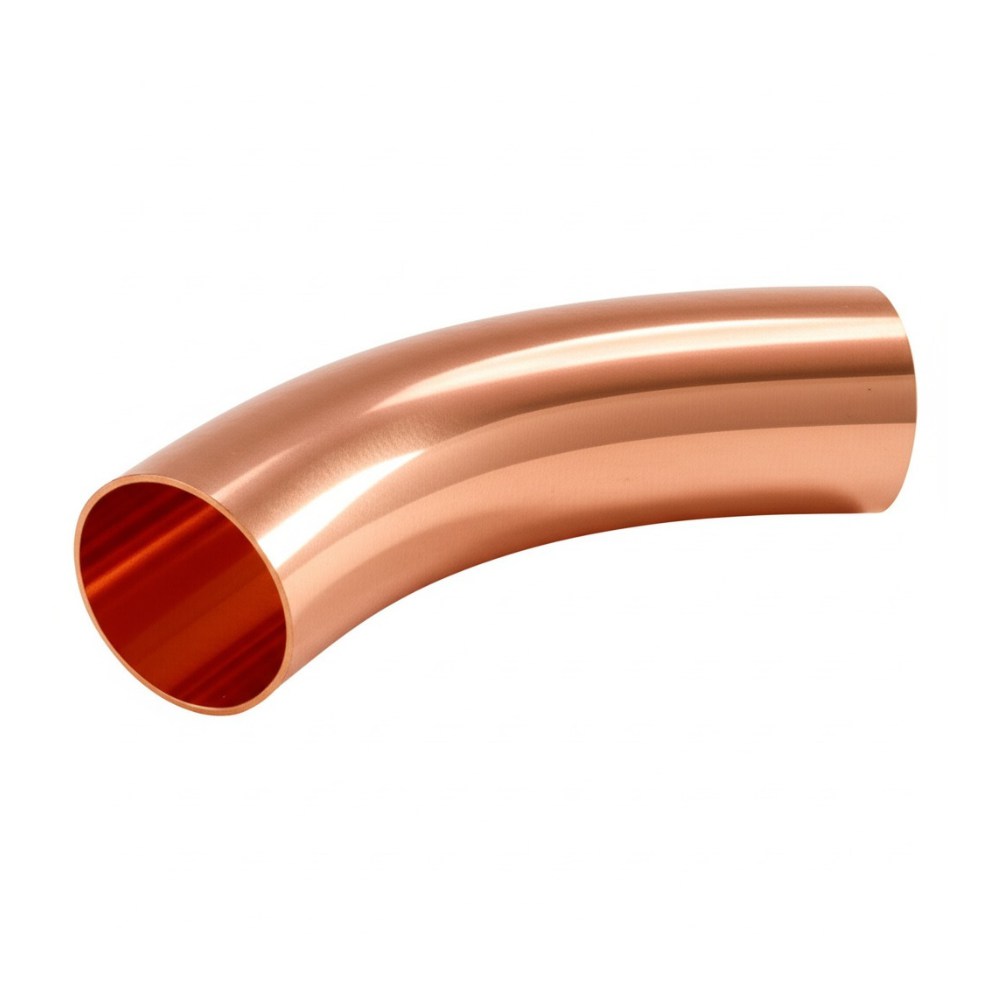

Copper (Common Grades: C101, C110) is renowned for its outstanding electrical and thermal conductivity, good corrosion resistance, and antimicrobial properties. It’s relatively soft and ductile.

Good for:

Why customers love it: “Its unparalleled thermal and electrical conductivity is essential for heat transfer and electrical applications, coupled with good corrosion resistance and ease of joining (soldering/brazing).”

Titanium (Common Grades: Grade 2, Grade 5/Ti-6Al-4V) offers an exceptional strength-to-weight ratio, outstanding corrosion resistance (especially in saltwater and chemical environments), and biocompatibility. It is more challenging and costly to machine.

Good for:

Why customers love it: “It delivers high strength comparable to steel at nearly half the weight, combined with exceptional corrosion resistance and biocompatibility for critical applications.”

Nickel Alloys (Examples: Inconel®, Monel®, Hastelloy®) are superalloys designed for extreme environments, offering excellent high-temperature strength, creep resistance, and outstanding corrosion resistance to specific aggressive chemicals. Difficult and expensive to machine.

Good for:

Why customers love it: “They provide unparalleled performance in extreme temperature and highly corrosive environments where other metals would fail, ensuring reliability in critical applications.”

Plastics

PVC / CPVC (Polyvinyl Chloride / Chlorinated Polyvinyl Chloride) are cost-effective, rigid plastics with excellent chemical resistance and electrical insulation properties. CPVC offers higher temperature resistance than standard PVC. Machining requires care to avoid melting.

Good for:

Why customers love it: “They are very affordable and offer broad chemical resistance for many fluid handling applications, with CPVC extending the usable temperature range.”

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its good toughness, impact resistance, rigidity, and ease of machining and bonding. Available in pipe form.

Good for:

Why customers love it: “Offers a good balance of toughness, rigidity, and cost-effectiveness, and it’s relatively easy to machine and assemble.”

HDPE / UHMWPE (High-Density Polyethylene / Ultra-High Molecular Weight Polyethylene) are known for their excellent chemical resistance, high impact strength (especially UHMWPE), low coefficient of friction, and abrasion resistance.

Good for:

Why customers love it: “Excellent resistance to a wide range of chemicals, very durable and impact resistant, with UHMWPE offering exceptional wear resistance for abrasive applications.”

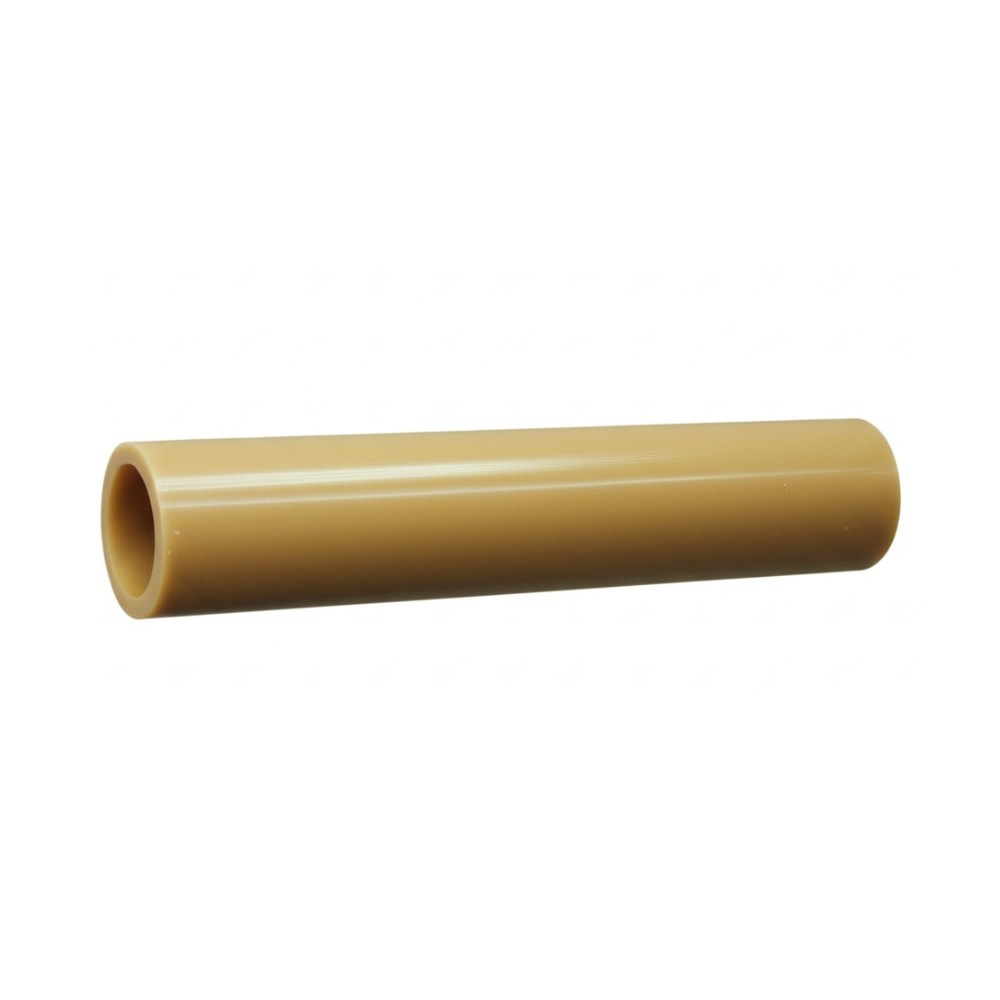

Nylon (PA) (Common Grades: 6, 6/6) is a strong, tough thermoplastic with good wear resistance, fatigue resistance, and chemical resistance to many oils and solvents. Can absorb moisture, affecting dimensional stability.

Good for:

Why customers love it: “Provides good mechanical strength and excellent wear resistance, making it suitable for mechanical components machined from tube or rod forms.”

Acetal (POM / Delrin®) is a high-stiffness engineering thermoplastic with excellent machinability, low friction, good wear resistance, dimensional stability, and resistance to moisture and many chemicals.

Good for:

Why customers love it: “Its excellent machinability allows for high-precision parts, combined with low friction, high stiffness, and good chemical resistance, making it a go-to for mechanical parts.”

Polycarbonate (PC) is a very tough, impact-resistant thermoplastic that is often transparent. It maintains its properties over a wide temperature range.

Good for:

Why customers love it: “Offers outstanding impact strength and optical clarity, making it ideal for applications requiring visibility and durability.”

Acrylic (PMMA) is a rigid thermoplastic known for its excellent optical clarity, weather resistance, and ease of machining and polishing. More brittle than Polycarbonate.

Good for:

Why customers love it: “Provides exceptional clarity similar to glass but is lighter and easier to machine, perfect for displays and aesthetic applications.”

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic offering excellent mechanical strength, high temperature resistance, chemical inertness, wear resistance, and biocompatibility (in specific grades). Expensive and requires specific machining know-how.

Good for:

Why customers love it: “It delivers exceptional performance under extreme conditions (temperature, chemical, mechanical stress) where other plastics and even some metals fail.”

Our pipes meet strict ASME B16.25 rules for:

1. Spool pieces

2. Manifolds

3. Wellhead parts

4. High-pressure systems

We create lightweight, strong components for:

1. Fuel lines

2. Thin-wall titanium tubing

3. Fluid systems

4. Engine parts

Perfect for:

1. Exhaust systems

2. Turbocharger pipes

3. Brake lines

4. Cooling systems

Special biocompatible parts for:

1. Fluid transfer tubes

2. Surgical tools

3. Medical equipment

Feature | Specifications |

Diameter Range | 6mm to 600mm (both seamless and welded pipes) |

Materials | Stainless steel, carbon steel, alloy steel, aluminum, titanium |

Tolerances | ±0.005 mm precision |

Certifications | ISO 9001:2015, ITAR, PED, Norsok |

Surface Finishes | Electropolishing, grit blasting, anodizing, powder coating |

We use several methods to create perfect pipe components:

For precise cutting and shaping

Clean, accurate cuts with both fiber and CO2 lasers

For strong, consistent joins

Perfect for pipes that need to be connected

X-ray and ultrasonic tests to check quality

We follow strict rules and provide:

Our experts can help with design for CNC machining to make sure your pipes are made in the most efficient way.

Ready to order perfect pipe components? Our team at Istar Machining is here to help!

Contact us today to discuss your pipe CNC machining needs and discover why we’re a top 5 CNC machining factory in China!

Standard orders take 10-15 days, but rush jobs can be faster.

50 pieces for prototypes, 500+ for production runs.

Yes! Free ground delivery for orders over $199 (except for very large items).

Absolutely! We regularly make parts that meet strict pressure requirements.

Usually 316L stainless steel or special alloys like Inconel® work best.

You almost never choose between a bearing and a bushing because of friction alone. You choose because of how you

Most mounting brackets do not fail because the metal was weak. They fail because a few small design and installation

Most of the time the choice is simple: if the part is thick, 3D, and tolerance-critical in low or mid