Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

You have likely heard people talk about polyamide and nylon. You might have even heard them used as if they mean the same thing. It can seem a little tricky, but I am here to make it simple for you. You can think about it in this way: every square is a rectangle, but not every rectangle is a square. In the same way, all types of nylon are polyamides, but not all polyamides are nylons. In this article, I will explain the differences and the things that are the same about polyamide vs nylon. We will look at their many different uses and help you learn which material is the best one for what you need. We will look at everything from how they are made to how they are used in items you see every day and in special things for factories.

Let’s begin with the simple facts. A polyamide is a kind of polymer. That is just a science word for a big molecule that is made of many smaller parts linked together again and again. For a polyamide, these parts that repeat are held together by special links called amide bonds. This is what makes them strong and helps them last a long time. You may be shocked to know that you can find polyamides in nature. Silk and wool are perfect examples of natural polyamides. People have used these materials for a very long time because they have great features.

Scientists also learned how to make man-made polyamides in a lab. These man-made types, including nylon, are now very important in many kinds of businesses. For example, companies that make cars and trucks use a lot of polyamide materials. They are so popular because of their great mechanical properties. This means they are very strong and last a long time. This makes them a top pick for everything from clothes to parts for cars. A polyamide can be a very useful plastic.

Now, we can talk about nylon. Nylon is a special kind of man-made polyamide. It was first created in the 1930s. A group of scientists at a company called DuPont made it. They wanted to make a material in the lab that was like silk, and they did a very good job. The first time nylon was sold in stores was for women’s stockings, and they were very popular. After that, it became much more common. It was then used to make many other items.

The thing that makes nylon special is its chemical structure. It is called an aliphatic polyamide. This means the tiny chains of atoms that make it up are long and straight. This structure is what gives nylon its well-known features: it is strong, tough, and stretchy. It is also hard to damage from rubbing or scraping, which makes it a very durable material. Nylon is a thermoplastic. This means you can melt it down and give it a new shape. That makes it easy to use for things like injection molding.

Many people get mixed up about this. Like I said before, nylon is a type of polyamide, but not every polyamide is a nylon. You can think of “polyamide” as a big family name. Then, “nylon” is like one of the famous kids in that family. The polyamide family also has other powerful materials like Kevlar and Nomex. These are called aromatic polyamides. They have a different molecular structure. This structure gives them even more strength and makes them better at handling heat than nylon.

So, you might hear people use the words polyamide and nylon to mean the same thing, but it’s not quite right. It’s like saying every car is a Ford. A Ford is a kind of car, but there are many other kinds too. When we talk about polymers, nylon is a very famous and common type of polyamide. But it is important to know it’s just one material in a much bigger family of materials. The biggest difference is that polyamides can come from nature or be man-made, but nylon materials are always synthetic.

As a whole family, polyamides have some wonderful features that make them very useful. One of the biggest ones is their strength. They have a high tensile strength. This means it is very hard to pull them apart. They are also famous for their durability. This means they last a long time and do not wear out easily. This is the reason they are often picked to make things that must last, such as carpets and car parts.

Another important feature of polyamides is their chemical resistance. They can handle oils, grease, and many other chemicals without being damaged. But, they can sometimes have a problem with moisture absorption. This means they can soak up water from the air. This can sometimes make them change their size and shape a little bit. How much water they soak up changes with each different type of polyamide. They also usually handle heat well. Some kinds are able to work in very extreme temperatures.

Just like there are different polyamides, there are also many types of nylon. You will often see them with numbers in their names, like Nylon 6 and Nylon 6,6. These numbers tell you how many carbon atoms are in the small building blocks, or monomer units, that make the polymer chain. This might sound a little complex, but it is what gives each type of nylon its own special features.

For instance, Nylon 6 is known for being stretchy and shiny. This makes it a great pick for clothes and carpets. Nylon 6,6 has a higher melting point and is a bit stiffer. Because of this, it is often used for things that need more strength and must handle heat better, like parts inside a car engine. Other common nylon types are Nylon 11 and Nylon 12. Nylon 11 is special because it can be made from plants, like castor beans. Nylon 12 is known for its amazing chemical resistance and for not soaking up much water. This makes it a wonderful choice for parts like the fuel lines in cars. There are also special nylons, like glass-filled nylon. This type has tiny glass pieces mixed in to make it even stronger and stiffer.

Nylon has many of the same general features as other polyamides. But there are some big differences when you check polyamide vs nylon against other materials in the polyamide family. For example, aromatic polyamides like Kevlar have much more strength and can handle heat much better. This is because of their stiff molecular structure. This is why Kevlar is used to make things like vests that can stop bullets, where you need the most strength you can get.

When you compare it to some other polyamides, nylon usually costs less and is easier to work with. This is a major reason why it is so widely used by so many different companies. For many consumer goods and factory uses, it gives a better balance of properties. It might not be the strongest or best material for handling heat. But it is a very popular material. This is because it has a good mix of mechanical properties, durability, and a low price.

| Feature | Nylon (Aliphatic Polyamide) | Aromatic Polyamides (e.g., Kevlar) |

|---|---|---|

| Strength | High | Extremely High |

| Heat Resistance | Good | Excellent |

| Flexibility | Good | Lower |

| Cost | Lower | Higher |

| Common Uses | Clothes, gears, items for home | Bulletproof vests, parts for planes |

The great versatility of both polyamide and nylon means you can see them in a lot of different items. For cars and trucks, for instance, you will see nylon used for parts like engine covers, air intake parts, and fuel lines. It is a perfect choice because it is strong, lightweight, and handles heat and chemicals well. Glass-filled nylon is often used for parts that must be very strong and stiff.

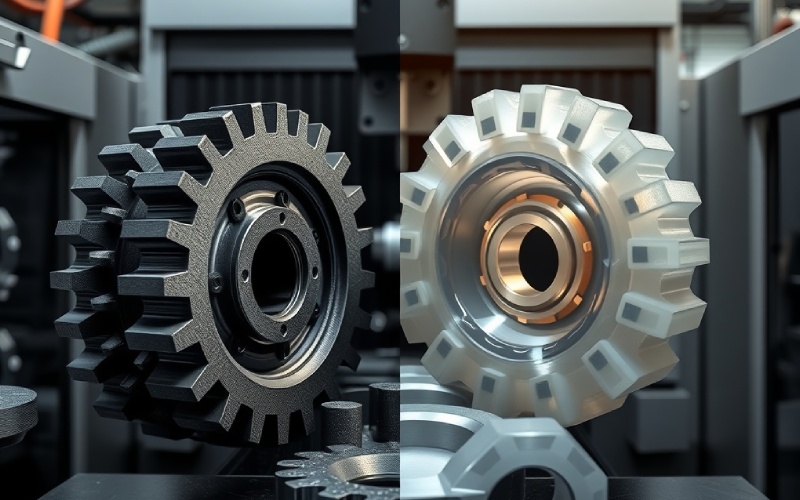

In the clothing world, nylon is a big star. It is used to make all kinds of things, from shirts and swimsuits to carpets and ropes. Its ability to stretch and be made into a very thin fiber are big pluses here. For jobs that need even more power, you might see other polyamides. Nomex, for example, is a polyamide that does not catch fire easily. It is used to make safety clothes for firefighters. Both polyamide and nylon are also popular for making 3D printed parts. They are especially good for making a working prototype to test an idea. They are also used a lot in injection molding to make many plastic parts at once.

A good way to see the real differences between nylon and other polyamides is to look at a car. Under the hood, you might find a gear made from nylon 6,6. This part needs to be strong. It also has to handle heat and have a slick surface to work right. The fuel lines that take gas to the engine could be made from nylon 12. This is because of its great chemical resistance and because it does not soak up much water.

Now, think about the airbags. The cloth they are made of must be super strong and hard to tear. This is where a very strong polyamide would be used. And for the tires, they might have strong cords inside them made from a tough polyamide like Kevlar. This gives them extra strength and durability. So, just by looking at one car, you can see how different kinds of polyamides, including different nylon materials, are picked for special jobs because of what they can do. This is a great example of the various applications these materials have.

Picking between the different kinds of polyamide and nylon is all about what you need for your job. If you are making something that has to be strong, last a long time, and not cost too much, a common type of nylon like nylon 6 or nylon 6,6 is usually a smart choice. They are great for everyday uses and are easy to find. You will see them in all kinds of things from consumer goods to parts for factories.

If your job needs something more, you will have to look at the special features of different polyamide materials. If you need a part that will be around water or wet air, nylon 12 could be a better pick. This is because it has low moisture absorption. If you need something that can handle very hot temperatures, you might have to check out a different kind of polyamide. And if you need the strongest material you can get, an aromatic polyamide like Kevlar is the one. But you should be ready to pay more for it. For parts made with injection molding, the choice of plastic also matters based on how easily it fills the mold.

The differences between polyamides are all because of their molecular structure. The kind of monomer building blocks used and how they are put together decide the final features of the polymer. As we have talked about, the long, straight chains of aliphatic polyamides like nylon make them flexible and tough. The stiff, ring shapes in the chains of aromatic polyamides like Kevlar are what make them so very strong.

Another big difference is the number of carbon atoms in the monomer building blocks. This is what the numbers in names like nylon 6 and nylon 12 are about. Usually, a bigger number of carbon atoms means the material will soak up less water and have better dimensional stability. This means it holds its shape better. So, even though all polyamides are held together by amide groups, these small changes in how they are made lead to a big group of materials with very different good and bad points. Knowing these differences between polyamides is very important for picking the right material for your needs.