Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Polycarbonate is a special kind of plastic that is very strong, light, and clear. Have you ever wondered what bulletproof windows, DVDs, or new eyeglass lenses are made from? The answer is often polycarbonate. This article will tell you everything you need to know about this wonderful material. I am going to give you a full guide that you will need to know about polycarbonate, from what it is to how it is used.

Let’s begin with the simple facts. When I first found out about it, the science behind it wowed me. Polycarbonate is a kind of thermoplastic. That is just a big word for a plastic that you can heat up. Then, you can shape it in a mold and let it cool down. You can even heat it up again and give it a new shape. The material will not break down when you do this. This makes it very useful for making things. It is a kind of polymer. This means it is made of long strings of tiny parts all joined together.

The science of how polycarbonate is produced is very interesting. These plastics are polymers that have carbonate groups in their chemical structures. To say it simply, the work often begins by mixing bisphenol a with sodium hydroxide. This step deprotonates the hydroxyl groups of the bisphenol. Then, this result is called another phenoxide. It reacts with phosgene to give a chloroformate. This final reaction from the diphenoxide makes the strong material we call polycarbonate. The special groups in their chemical makeup are what give polycarbonate its famous strength.

Every great material has a beginning. The story of polycarbonate is very interesting. This is because two people found it at nearly the same time. In 1953, a German scientist, Dr. Hermann Schnell at Bayer, created the first straight-chain polycarbonate. Just a few days after that, a chemist named Daniel Fox at General Electric in the United States created it too, all on his own. Both of them saw the great promise of this new plastic.

Once they understood how they made polycarbonate, companies started making it for people to buy in the late 1950s. They knew its amazing strength and clearness would be good for many things. It was plain to see from the start that this was not just a regular plastic. It was stronger and could be used in more ways than other materials they had back then. It quickly became widely used. The use of polycarbonate has been growing from that time on.

So, what is it that makes polycarbonate so great? It all has to do with its special physical properties. The most famous of its characteristics of polycarbonate is its amazing impact strength. It is very, very strong when it gets hit. It is so strong that it is often called virtually unbreakable. This means it is almost impossible to break. This makes it great for safety glasses, police shields, and other kinds of protective gear. I have seen a sheet of it get hit with a hammer and not even get a mark.

Besides being strong, polycarbonate is also very lightweight. This is especially true when you put it next to glass. It also has great optical properties. This means you can see through it very clearly. It also has high light transmission, so it lets a lot of light pass through, almost like glass does. This is why it is great for making a lens or a window. Last, it has good heat resistance. It can stand up to high temperatures better than many other plastics. It has a high melting point, which helps it keep its shape when it gets hot. This special group of mechanical properties is why the material is used for many hard jobs.

People often ask me, “Why should I use polycarbonate and not glass?” For many projects, the answer is easy: safety and how long it lasts, which is its durability. Regular polycarbonate is about 250 times stronger than regular glass. It is also 30 times stronger than acrylic. This means it can handle hard hits, stormy weather, and even people trying to break it on purpose far better than glass can. It can take a big hit without cracking or breaking.

Another large reason is its weight. Polycarbonate is about half as heavy as glass. This makes it much easier to work with and easy to install. Think about trying to put a heavy glass panel on a roof. Now, think about doing that with a lightweight polycarbonate sheet. It makes the work go faster and be safer. Because it is so strong and light, it is a great pick to replace glass in places like garden greenhouses, bus stops, and safety walls. The applications of polycarbonate are increasing all the time.

Yes, not every kind of polycarbonate is the same. There are many different polycarbonate grades made for certain tasks. This is one of the types of polycarbonate you should know. For instance, if you are making something that will be outside, like a greenhouse roof, you would want a kind of polycarbonate with a special coat for UV protection. This coat gives it resistance to UV light. It also gives the sheet protection on both sides. This stops it from turning yellow and weak in the sun.

There are other special kinds, as well. Some polycarbonate sheets are made to be hard to scratch. This is helpful for things that people touch a lot. There are also kinds that are made to slow down fire. In these, special chemicals are used to enhance fire safety. You can even find bpa-free polycarbonate for certain uses. These different kinds mean you can find the right type of polycarbonate for almost any project you can dream up.

When you have a material that is this strong and can be used in so many ways, you find uses for it all over the place. I have seen polycarbonate used in many different fields of work. The use of polycarbonate is very frequent. Here are some of the most widespread applications of polycarbonate:

This combination of properties is why polycarbonate is also used in engineering for machine covers and clear cases. It is mainly used in any place where you need both strength and clearness.

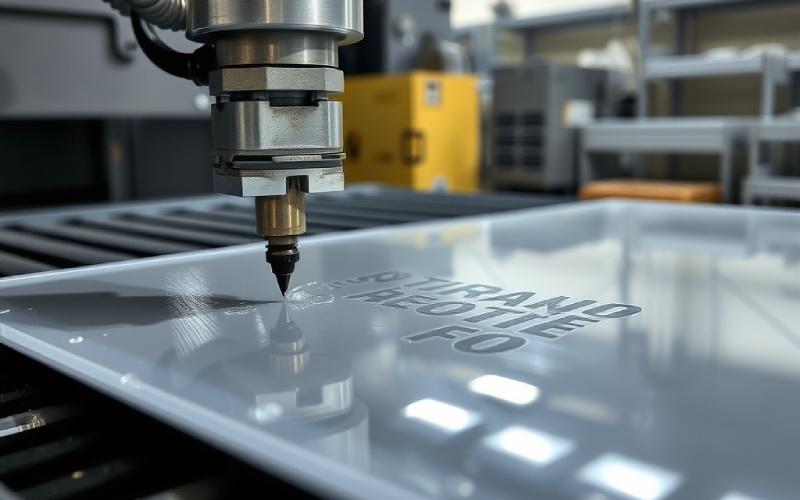

So how do we change tiny balls of polycarbonate into useful things like a car headlight or a water bottle? The most common way is a method called injection molding. In this method, the raw polycarbonate material is melted. Then it is pushed, or injected, into a specially made mold. The hot liquid plastic fills up the whole mold. After it cools down and gets hard, the mold is opened. Then you have a finished part. The injection method is very quick. This makes it good for making thousands of the same polycarbonate products.

Another neat thing about polycarbonate is that you can work with it even when it is not heated up to its melting point. You can bend a sheet of it and it can be formed at room temperature without cracking. This is not common for a material that is so strong. This lets people make a prototype or special shapes without needing big, expensive heating machines. You can also cut it with normal tools. This makes it a top choice for big companies and for people doing projects at home.

This is a question I hear a lot, and it is a very important one. The worry is about a chemical called bisphenol A, or BPA. Most regular polycarbonate is made with BPA. Some studies have shown that very small bits of BPA can move into food or drinks from containers made of polycarbonate. This has made some people worried about using it in things like baby bottles or containers for storing food.

Because of these worries, many companies now sell bpa-free polycarbonate for any product with polycarbonate that needs food contact. These special kinds are made in a different way or with different chemicals to keep BPA out completely. It is important to look at the product’s information. Government groups in many countries have rules for materials used for food contact. There are many polycarbonate choices that pass these tough safety tests.

Polycarbonate and acrylic are two of the most well-known clear plastics that people use. They are often mixed up. I have used both of them for different jobs, and each one has its good points. Acrylic, which is sometimes called Plexiglas, is also strong. But polycarbonate is much stronger when it comes to impact resistance. If you need something for a place that needs to be very secure, polycarbonate is the best pick.

Here is an easy chart to help you see how they are different:

| Quality | Polycarbonate | Acrylic |

|---|---|---|

| Impact Strength | Very, Very High (250x glass) | High (17x glass) |

| Clearness/Light | Very Good (88% of light passes) | Excellent (92% of light passes) |

| Scratch Resistance | Okay (can be coated) | Good |

| Price | Costs More | Costs Less |

| How Bendy It Is | Very Bendy | Stiffer |

| Drilling | Very hard to crack | Can crack if not careful |

So, if you need the very strongest material, pick polycarbonate. If price is a bigger issue and you do not need extremely high impact strength, acrylic could be a good choice. I always tell people to pick the right tool for the right job.

After all this information, what are the most important things to remember? The advantages of polycarbonate are easy to see. I think the benefits of polycarbonate make it one of the most helpful materials that we can use today. I have worked with it on many, many projects, and it always wows me. This special thermoplastic polymer is amazing.

Here are the key good points you get when you pick a quality polycarbonate:

This powerful combination of properties is making it ideal for thousands of products we use each day. Polycarbonate is highly useful.