Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

A powder coat gives you a nice-looking and strong coating. It is much stronger than regular paint. You can imagine it’s like a plastic shell for metal things. This article will explain everything about this great powder finish. You will find out how the powder is created, how it is put on, and what makes it so tough. After reading, you will see why lots of people pick a powder coat for the things they make.

A powder coat is a special kind of covering. It is not like wet paint because powder coating is a dry powder. It looks like a very fine powder, a lot like flour. People use this dry powder to make a tough and safe coating on many different things. The method doesn’t use any liquids, called a solvent, to hold it all together. This makes a powder coat very different from normal paint.

The basic idea is easy to understand. You put this powder onto an item. Next, you heat up the item. The heat makes the powder melt and spread out. When it gets cool again, the powder turns into a hard layer. This makes a very strong and good-looking finish. This way of using a dry powder has become well-liked because it is so strong and looks so good. The finished powder coat is much tougher than what you get from most wet paints.

The special powder for a powder coat is a mix of a few things. The most important part is a polymer resin, which is a kind of plastic. Other parts are added in, like a pigment to give it color, a special agent that helps it harden, and other additives. These extra bits help the powder spread out smoothly and give it the right appearance. The recipe for the powder can be changed to make different colors, feels, and levels of strength.

To create the powder, all the parts are heated up and mixed together. They are heated so much that they melt into a thick liquid. Then, this mix is allowed to get cool. After it becomes solid, it is crushed into a very fine powder. Every tiny piece of the powder contains all of the parts. This makes sure the final powder coat is the same all over. That is how the dry powder is made before it is put on something.

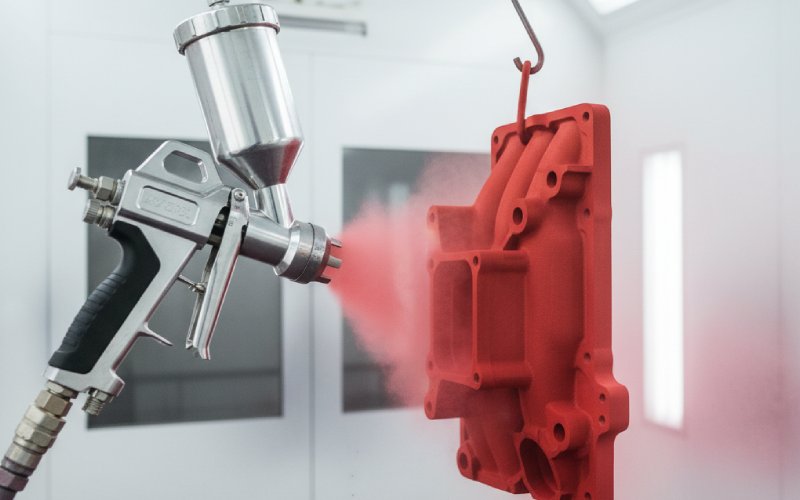

The way powder coating is done is very neat. The first thing you have to do is clean the item, also called the substrate, really well. The surface needs to have no oil, dirt, or rust on it. When the surface is clean, the powder sticks much better, and you get a nicer finish. At times, the item is also covered with a chemical. This helps stop rust and makes the powder coat last for a longer time.

The most popular way to put the powder on is by using a special spray gun. This spray gun gives a special electric power, an electrostatic charge, to the powder. This electric power makes the tiny bits of powder stick to the grounded item. It works like a sock sticking to your shirt after being in a dryer. The powder covers the whole item, even in spots that are hard to get to. This method helps make the coating the same thickness everywhere. This is the way powder coating is put on to make a wonderful finish.

Once the powder is on the item, the next thing to do is to cure it. To make the powder cure, the item is put inside a special kind of oven. The heat from the oven is very important for this step. The heat causes the powder to melt. When the powder melts, it begins to spread out and join together. This makes a smooth, wet-looking layer on the item’s surface. This is a very important part of the powder coating process.

While the powder keeps baking in the oven, a chemical change takes place. The resin and the special agent in the powder join together. This action, known as chemical bonding, makes a very strong, linked layer. When the item is finished in the oven, you let it get cool. As it cools down, the melted powder becomes hard. The powder turns into a very tough coating. This finished, cured coating is why a powder coat is so strong and doesn’t get chips or scratches easily. The powder must cure all the way to be very strong.

There are two main kinds of powder that people use for a powder coat finish. Their names are thermoset and thermoplastic. A thermoset powder changes its inside makeup when it gets hot. The powder has a chemical reaction inside the oven. This makes very strong connections that make the finish super hard. After a thermoset powder is cured, you cannot make it melt a second time. This kind of powder is perfect for things that have to stand up to a lot of heat. Epoxy powder is a popular kind of thermoset powder.

The second kind of powder is named thermoplastic. A thermoplastic powder does not change its inside structure when you heat it up. It will melt and spread out when it gets hot, and then it gets hard when it cools down. You can heat it up again, and it will melt all over again. This kind of powder is very bendy and can make thicker layers of coating. This makes thermoplastic powder useful for items that need to handle getting hit. The kind of powder you pick should be based on how the item will be used.

A lot of people believe a powder coat is just for metal things. For many years, that was correct. Powder coating is great for metal because metal can take the heat from the oven. It is also easy to ground metal for the electrostatic charge. Many factory parts, car parts, and things for the home are made of metal and have a powder coat on them.

But today, powder coating has improved a lot. New kinds of powder have been invented that can cure with less heat. This means that you can now put a powder coat on other kinds of materials. It is now possible to apply a powder coat to things such as wood and medium density fiberboard (MDF). You can also see a powder finish on certain plastic things. This makes it possible to use powder coatings for many types of products, not only metal ones. Some items not made of metal can now get a powder finish.

There are a lot of good reasons to pick a powder coat instead of wet paint. A major plus is how long it lasts. A powder coat finish is a lot tougher than paint. It is better at fighting off scratches, chips, and color loss from sunlight, which is called UV light. This means your things will stay looking nice for a much longer time. This is true even if they are kept outside in bad weather. The long-lasting quality is a huge benefit.

Another good point is how thick the coating is. You can put on a thicker layer of powder in just one try. With wet paint, you may need to apply many coats to get it that thick. Also, the paint could run or have drips. The powder stays right where you put it, which gives you a smooth and even finish. This makes the powder coat look very well-done. The powder also doesn’t require a solvent, and that is much better for our world.

| Feature | Powder Coat | Liquid Paint |

|---|---|---|

| Durability | Very high, resistant to scratch | Lower, can chip and scratch |

| Appearance | Uniform, smooth finish | Can run or drip |

| Thickness | Thicker coatings in one go | Needs multiple coats |

| Environment | No solvent, less waste | Uses solvent, has VOCs |

| Waste | Overspray powder can be recycled | Overspray is wasted |

A powder coat is a wonderful choice for many jobs, but it does have one main drawback. It can be tough to make very thin layers of coating. A powder coat usually makes a thicker finish. If you need a layer that is super thin, wet paint could be a better option. The bits of powder are a certain size, and that makes it hard to get a really thin finish.

Something else to consider is matching colors for small jobs. Making a special color of powder can be expensive if you only need a little bit. It is easier to mix small amounts of wet paint. Also, because you need an oven, you are limited by how big your oven is. You can only put a powder coat on items that are small enough to fit inside and can take the heat to cure the powder.

The kind of powder you pick is very important. It will change how the final finish looks and what it can do. For instance, if you are making something to be used inside, like a metal desk, an epoxy powder is a wonderful choice. Epoxy powders are very tough and are good at resisting chemical spills. But, epoxy powder is not good at handling sunlight. It can lose its color if it is out in UV light for too long.

For things that will be used outdoors, you should pick a different kind of powder. A polyester powder is right for outdoor things like garden furniture or fences. This powder is very good at resisting ultraviolet light and will not lose its color easily. Some powders are made to be very smooth. Other powders can make a finish that is rough and has a texture. The resin, the pigment for color, and the flow modifiers in the powder all mix to make the final look and feel. The kind of powder you should use will be based on what you are making.

A powder coat is thought of as a choice that is good for the environment. This is because the powder has no volatile organic compounds, which are also called VOCs. Wet paint uses a liquid called a solvent to keep it from drying out. When that paint dries, the solvent goes into the air. These are VOCs, and they can be bad for nature. Because powder coating is made of dry powder, it does not let go of these bad chemicals.

There is another reason a powder coat is a good choice for the earth: you can reuse the powder. When you spray the powder on an item, some of it doesn’t stick. This extra powder is known as overspray. With a powder coating setup, you are able to gather this extra powder and use it another time. This means that almost nothing is wasted. This is good for saving money and is also better for our world. Being able to reuse the powder makes the whole method very smart and effective.