Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

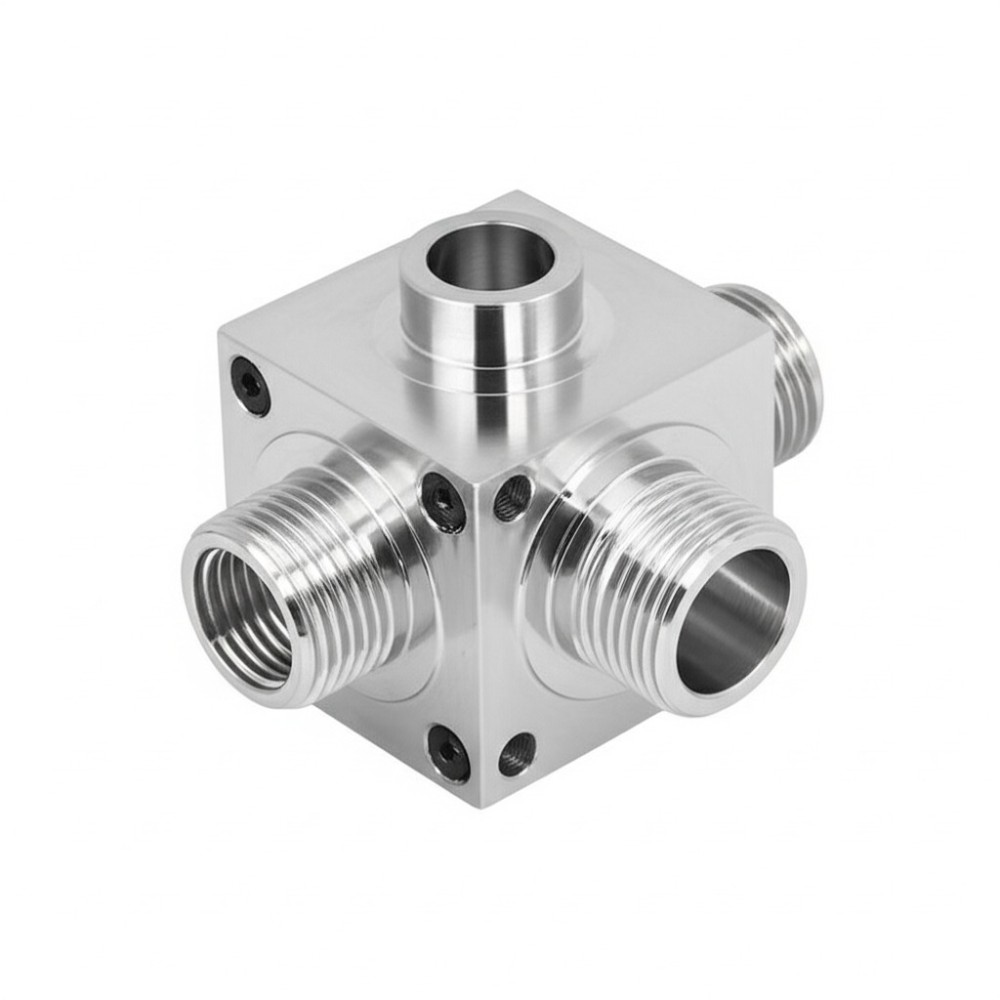

At Istar Machining, we’re experts in precision CNC machining – the process that creates perfect parts for important industries. Let’s explore what makes this technology so amazing and how it can help your business!

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

We can machine almost any material you need:

Our titanium CNC machining service is perfect for aerospace and medical parts that must be both strong and lightweight.

At Istar Machining, we offer these amazing services:

What We Do | How Precise We Are | Why This Matters |

5-axis machining | ±0.005mm (ISO 2768-FH) | Makes complex shapes possible with perfect accuracy |

Swiss-style CNC | Ultra-smooth surfaces | Creates tiny medical parts with perfect finish |

CMM quality testing | Laser scanning verification | Confirms every part meets exact specifications |

Fast prototypes | 72-hour turnaround | Gets your ideas from design to reality quickly |

Istar Machining stays ahead with the latest technology:

Quality isn’t just a word for us – it’s built into everything we do:

Your designs stay secret with our secure systems

Our smart processes reduce waste by 30%

Our team is available when you need help

From raw material to finished part, we handle everything

We make the whole process easy:

Our engineers help improve your designs for manufacturing

We make test parts quickly so you can verify designs

Once approved, we make your parts in any quantity

We handle anodizing, polishing, painting - whatever you need

Every part is checked before shipping

Ready to experience the Istar Machining difference?

Don’t settle for less than perfect parts. Contact Istar Machining today to discuss your precision CNC machining needs.

Email: [email protected]

Website: www.istarmachining.com

Let Istar Machining show you what precision really means!

Precision CNC machining is like super-accurate cutting with computer control. Our machines follow exact instructions to shape materials into perfect parts. We can make parts as exact as ±0.005mm – that’s thinner than a human hair!

When you need parts that work perfectly every time, precision CNC machining is the answer. At Istar Machining, we use advanced machines that follow computer programs to remove material with incredible accuracy.

Our standard production time ranges from 1-3 weeks depending on complexity and quantity. For urgent needs, we offer expedited services with some prototypes available in as little as 72 hours. We’ll always provide clear timelines when quoting your project.

We have no minimum order requirement! Whether you need a single prototype or thousands of production parts, Istar Machining can accommodate your needs. We price our services fairly at all quantities.

Absolutely! Our engineering team offers Design for Manufacturing (DFM) feedback to improve part functionality, reduce costs, and streamline production. We can often suggest small changes that make big differences in the final product.

Yes! We take data security seriously and protect your intellectual property. All customer designs are treated as confidential, and we’re happy to sign NDAs before beginning work on sensitive projects.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or