Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

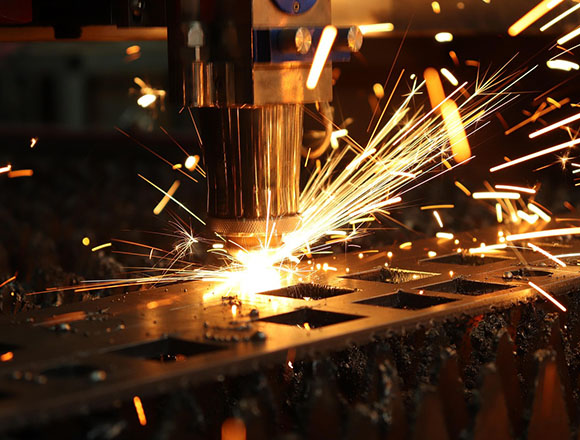

Are you looking to make your design ideas come to life quickly? Prototype CNC milling might be just what you need! At Istar Machining, we help turn your drawings into real parts you can touch, test, and show off.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Prototype CNC milling is a way to make early versions of your parts. We use special computer-controlled machines to cut materials into the exact shape you need. Think of it like a super-precise carving tool that follows your design perfectly!

Our cnc prototype machining service helps you test your ideas before spending lots of money on mass production.

To get the best results from CNC milling, we follow these key design rules:

These rules can help:

For your digital design files, use formats like STEP, IGES, or SolidWorks files. These work well with most CNC shops.

Different materials are better for different jobs. Our CNC milling capabilities allow us to work with a wide range of materials to meet your specific project needs. Here’s what works best:

Metals

Aluminum (Common Grades: 6061, 7075, 5052, 2024, MIC-6) is lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is very machinable.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications.”

Stainless Steel (Common Grades: 303, 304, 316/316L, 17-4 PH) offers excellent strength, high corrosion resistance, heat resistance, and a premium finish.

Good for:

Why customers love it: “Its superior corrosion resistance and strength make it ideal for harsh environments or applications requiring durability and hygiene.”

Mild Steel (Common Grades: 1018, A36) is a cost-effective ferrous metal known for its good machinability, weldability, and strength, though it requires finishing (like plating or painting) to prevent rust.

Good for:

Why customers love it: “Offers good strength and ease of fabrication at a significantly lower cost than stainless or alloy steels.”

Alloy Steel (Common Grades: 4140, 4340) contains additional alloying elements (like chromium, molybdenum) for enhanced strength, hardness, toughness, and wear resistance compared to mild steel, often requiring heat treatment.

Good for:

Why customers love it: “Provides significantly higher mechanical properties than mild steel for demanding applications requiring wear resistance and strength.”

Brass (Common Grade: C360 / CZ121) is known for its exceptional machinability (often the standard for comparison), good corrosion resistance, electrical conductivity, and attractive gold-like appearance.

Good for:

Why customers love it: “It’s incredibly easy and fast to machine, reducing costs, while offering good mechanical properties and a desirable look.”

Copper (Common Grades: C101, C110) is prized for its outstanding electrical and thermal conductivity, second only to silver. It also has good corrosion resistance.

Good for:

Why customers love it: “Unbeatable thermal and electrical performance for applications where efficient transfer of heat or electricity is critical.”

Titanium (Common Grades: Grade 2, Grade 5 / Ti-6Al-4V) boasts an exceptional strength-to-weight ratio, excellent corrosion resistance (especially to saltwater and chemicals), and biocompatibility. It is more challenging and costly to machine.

Good for:

Why customers love it: “Offers ‘aerospace-grade’ performance combining lightweight, high strength, and near immunity to corrosion, essential for critical applications.”

Magnesium (Common Alloys: AZ31, AZ91) is the lightest structural metal, offering a very high strength-to-weight ratio but with lower corrosion resistance than aluminum and specific machining considerations (fire risk).

Good for:

Why customers love it: “Provides significant weight savings compared to aluminum while maintaining good strength, ideal for lightweighting projects.”

Plastics

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its toughness, impact resistance, ease of machining, and ability to hold good dimensional stability. It’s easily painted or glued.

Good for:

Why customers love it: “A cost-effective and versatile ‘workhorse’ plastic for prototyping, offering a good balance of mechanical properties and ease of processing.”

Polycarbonate (PC) is a strong, impact-resistant thermoplastic, often used when transparency or high toughness is required. It maintains properties over a wide temperature range.

Good for:

Why customers love it: “Exceptional impact strength and optical clarity make it perfect for tough, transparent applications.”

Acrylic (PMMA) is known for its excellent optical clarity, rigidity, and weather resistance. It’s more brittle than Polycarbonate but easier to polish to a high-quality finish.

Good for:

Why customers love it: “Offers glass-like clarity and brilliance at a lower weight and cost, with good machinability for sharp details.”

Nylon (PA) (Common Grades: PA6, PA66, often glass-filled variants) is known for its toughness, high wear resistance, good chemical resistance, and self-lubricating properties (in some grades).

Good for:

Why customers love it: “Excellent wear resistance and toughness make it ideal for moving parts or components subjected to friction and impact.”

Delrin (POM / Acetal) offers high stiffness, excellent dimensional stability, low friction, good wear resistance, and outstanding machinability, producing clean, sharp features.

Good for:

Why customers love it: “Its combination of stiffness, low friction, and superb machinability makes it a top choice for precise mechanical components.”

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic with exceptional mechanical strength, stiffness, high-temperature resistance (continuous use often >250°C), excellent chemical resistance, and inherent flame retardancy. It is expensive.

Good for:

Why customers love it: “Provides ultimate performance in extreme temperature, chemical, and mechanical stress environments where other plastics fail.”

Ultem (PEI) (Polyetherimide) is another high-performance thermoplastic offering high strength and rigidity at elevated temperatures, broad chemical resistance, and good dimensional stability. Often seen as a slightly lower-cost alternative to PEEK for some applications.

Good for:

Why customers love it: “Offers excellent high-temperature performance and mechanical strength, bridging the gap between standard engineering plastics and PEEK.”

HDPE (High-Density Polyethylene) is a cost-effective plastic with excellent chemical resistance, good impact strength (especially at low temperatures), and low moisture absorption. It’s relatively soft and has a low coefficient of friction.

Good for:

Why customers love it: “Excellent chemical resistance and durability at a very low cost, ideal for corrosive environments or non-critical mechanical parts.”

PVC (Polyvinyl Chloride) is known for its excellent chemical resistance (especially to acids and bases), good electrical insulation, and inherent flame retardancy. It’s rigid and relatively low cost.

Good for:

Why customers love it: “Outstanding chemical resistance and electrical insulation properties combined with affordability.”

Composites / Other

G-10 / FR-4 are glass-reinforced epoxy laminates. They offer high mechanical strength, excellent electrical insulation properties, low moisture absorption, and good dimensional stability. FR-4 is flame retardant. Machining produces abrasive dust.

Good for:

Why customers love it: “Provides a robust combination of mechanical strength, stiffness, and excellent electrical insulation.”

Machinable Foam / Tooling Board (Polyurethane or Epoxy based) are rigid, dense foams designed for easy and fast machining. They are used primarily for modeling, patterns, and molds rather than functional parts. Density varies widely, affecting finish and strength.

Good for:

Why customers love it: “Allows for very fast and cost-effective machining of complex shapes for modeling, patterns, and tooling applications.”

We make lightweight, strong parts for planes and drones. These parts need to be super precise because lives depend on them. Our machines can make parts with tiny details down to ±0.001″ accuracy.

For medical tools and implants, we work with special materials that are safe for the human body. These prototypes help doctors and engineers test new ideas that could save lives!

Car parts often need to be tested under tough conditions. We make engine parts, transmission components, and EV battery housings that can handle heat and stress during testing.

Phone cases, heatsinks, and connector parts need to fit perfectly with other components. Our CNC milling gives them a smooth finish that looks great.

Robot parts need to move smoothly together. We make housings for motors, joint pieces, and gripper parts that work without sticking or breaking.

For factory machines, we can make custom gears, valve bodies, and pump parts that stand up to heavy use. These parts often need to be made from tough steel.

Wind turbine parts, solar panel mounts, and more need to last outdoors for years. We make corrosion-resistant prototypes that can handle harsh weather.

We know you need parts quickly! We can deliver in 1-5 days for most projects.

Our machines can make parts with tiny details as small as ±0.001″. That's about 1/4 the thickness of a human hair!

We have 3-axis, 4-axis, and prototype cnc milling machines to handle any shape you need, from simple to complex.

Our team will check your design before cutting starts. We might suggest small changes to make your part work better or cost less.

After milling your prototype, we can add different finishes:

As one of the top 5 CNC machining factories in China, we focus on making high-quality, precise parts. Our cnc milling service has helped companies from small startups to big corporations bring their ideas to life.

Need just one part? No problem! We don’t make you order more than you need.

You’ll see exactly what you’re paying for – materials, machine time, and finishing.

Our team helps from start to finish, making sure your prototype turns out just right.

Upload your CAD files (like STEP or IGES format)

We'll tell you the price and timeline within 1 hour

Our skilled machinists program the CNC machines

Every part is inspected before shipping

Your parts arrive on time, ready to use

Don’t let your great idea stay just a drawing! Let us help you make it real with our prototype CNC milling service. Upload your design today or contact us with questions.

Whether you need a simple plastic test piece or a complex aluminum cnc machining project, we have the skills, machines, and experience to get it done right.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or