Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

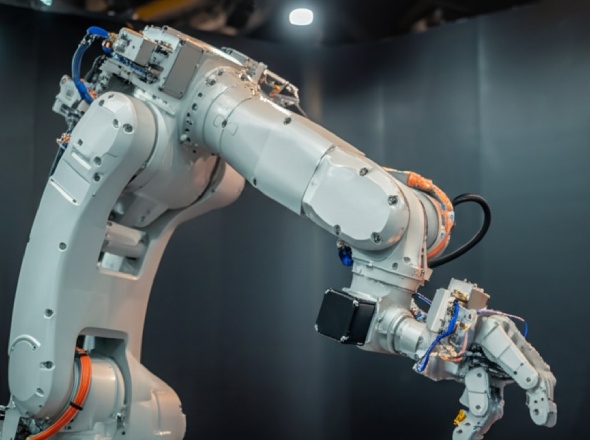

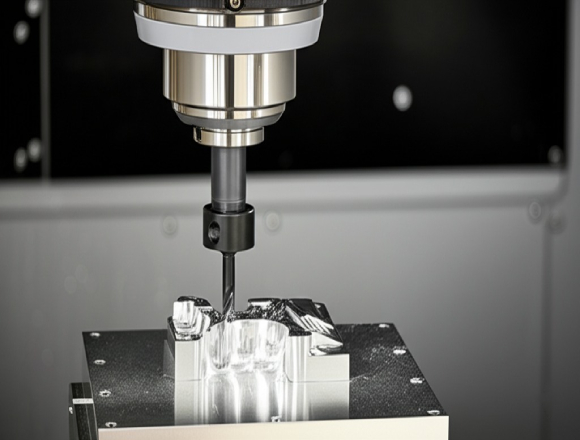

Are you looking for top-quality CNC machining services for your robotics projects? At Istar Machining, we make robot parts that work perfectly every time. Our machines can create the special parts that robots need to move, sense, and work right.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

We know robots need parts that are super precise. That’s why our team uses the best machines and skills to make sure your parts fit just right. Whether you need parts for factory robots, medical robots, or flying drones, we can help!

What We Offer | Why It Matters for Robots |

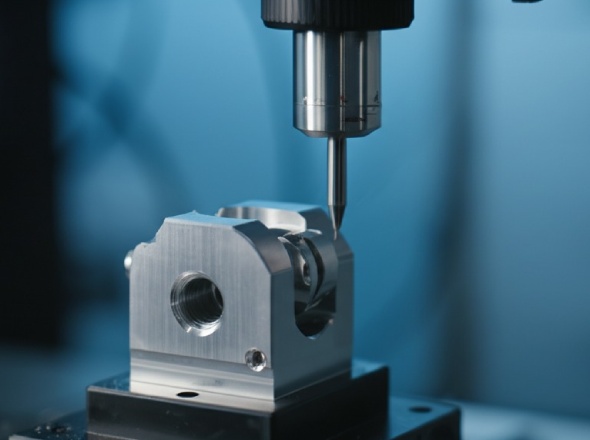

Tolerance: ±0.001mm | Your robot arms and grippers will move smoothly without sticking or getting stuck |

Special Materials: Aluminum 6061, Stainless Steel 316L | Light parts that don’t break or rust, perfect for all kinds of robots |

5-Axis CNC Machining | We can make complex shapes that simple machines can’t make |

Super Smooth Finish: Ra 0.4μm | Helps sensors work better by reducing signal problems |

Fast Delivery: 7-15 Days | Get your robot prototypes quickly to test your ideas |

Quality Certificates: ISO 9001, AS9100 | You can trust our parts for even the most important robots |

Surface Treatments: Anodizing | Makes parts stronger and protects them from weather and damage |

Big Parts Possible: Up to 500x300x200mm | We can make large chassis parts and housings for moving robots |

Custom Parts | Special grippers and tools made just for your unique robot needs |

Smart Manufacturing | Our computers help us make parts with less waste and more precision |

We can create almost any part your robot needs:

Industrial robots need tough parts that can work all day without breaking. Our CNC machining service creates parts for:

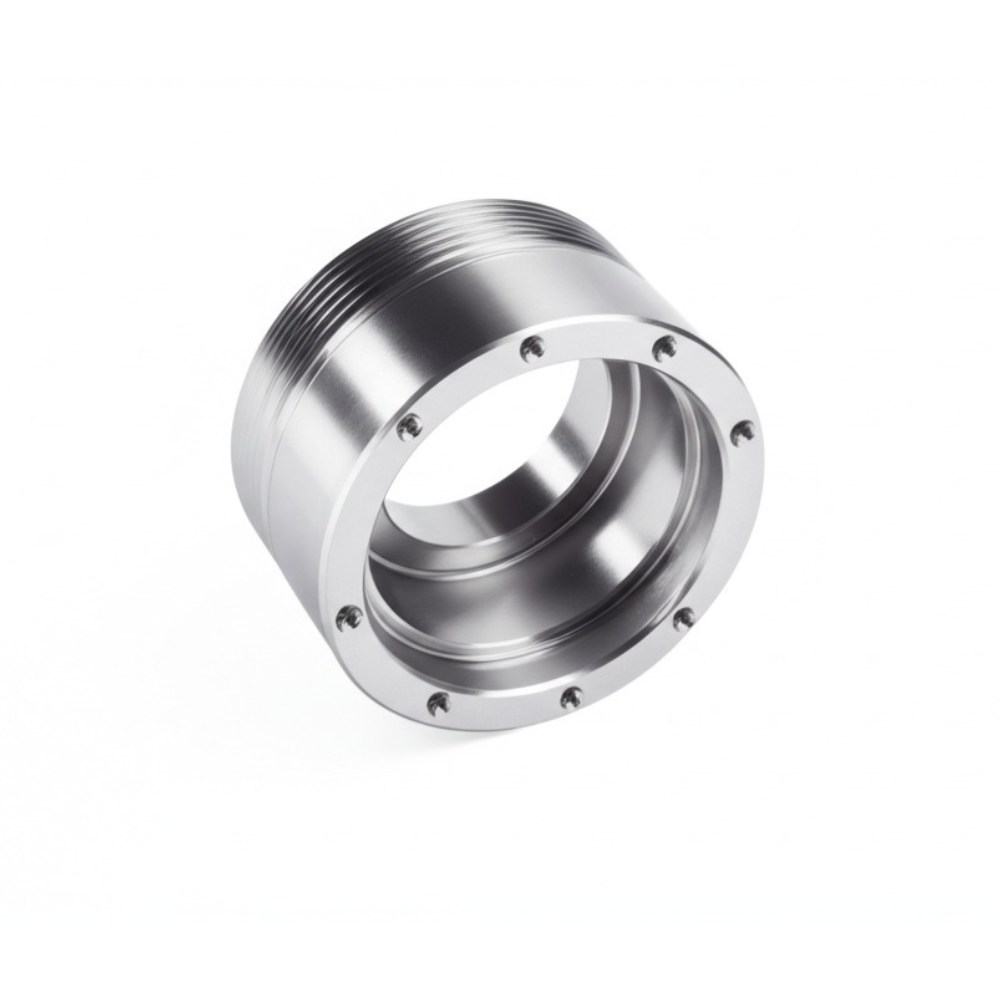

These parts have ±0.001mm tolerance so they move perfectly and don’t wear out fast. We use aluminum for light weight and stainless steel for durability.

Medical robots need extra-clean, super-precise parts. Our precision CNC machining creates:

Our medical robot parts meet strict health rules and have the smooth finish needed for medical use.

Drones need parts that are both strong and light. We make:

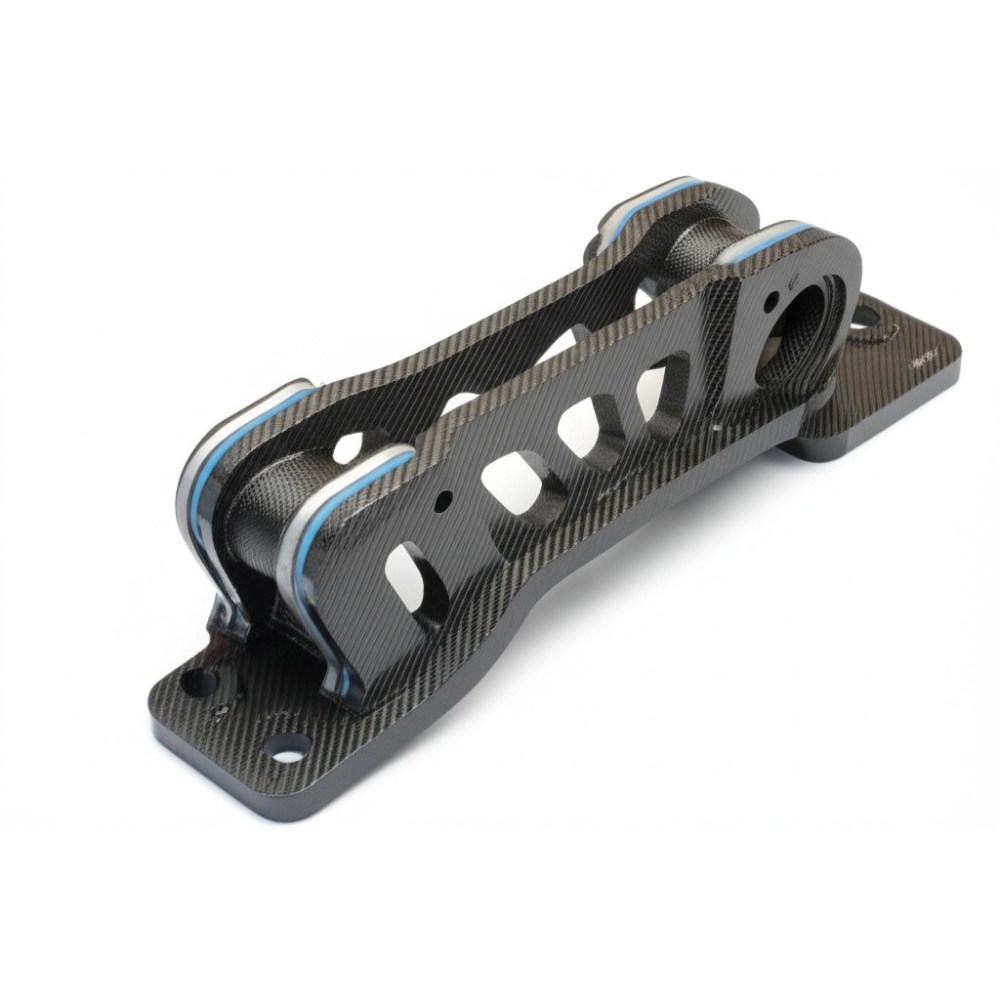

Using our 5-axis machining, we can create complex, lightweight parts that help drones fly longer and better.

Cobots work next to people, so they need safe, smooth parts. We make:

Robots need parts that fit just right. Our machines can make parts with ±0.001mm tolerance – that’s thinner than a human hair! This means your robot’s moving parts will work smoothly without sticking or wobbling.

Our shop has important certificates that show we meet high standards:

This means our parts are good enough for medical robots, space robots, and other important uses.

When you’re developing a new robot, you need parts fast. We can deliver:

We use CNC prototype machining to help you test ideas quickly!

Our advanced Robot CNC machining capabilities allow us to work with a diverse range of materials to meet your specific project needs, from large-scale sculptures and molds to intricate components. Here’s a look at the materials we frequently work with:

Metals

Aluminum (Common Grades: 6061, 7075, 5052, 2024, MIC-6) Aluminum is lightweight, corrosion-resistant, possesses excellent thermal and electrical conductivity, and is highly machinable. Its strength-to-weight ratio makes it ideal for numerous applications.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications, especially where weight is a concern.”

Stainless Steel (Common Grades: 303, 304, 316, 416, 17-4 PH) Known for its excellent corrosion resistance, strength, and hygienic properties. Different grades offer varying levels of machinability, weldability, and resistance to specific environments.

Good for:

Why customers love it: “Its durability, resistance to rust and staining, and clean appearance make it perfect for applications requiring longevity and exposure to demanding environments or sanitation requirements.”

Mild Steel (Common Grades: 1018, A36) A low-carbon steel that is cost-effective, strong, highly machinable, and weldable. It is prone to rust and typically requires a protective finish (painting, plating, powder coating).

Good for:

Why customers love it: “It’s an affordable and versatile workhorse material that’s easy to machine and weld, ideal for structural applications and general parts where corrosion resistance isn’t the primary need.”

Alloy Steel (Common Grades: 4140, 4340) Steel alloyed with elements like chromium, molybdenum, and nickel to enhance properties such as hardness, strength, toughness, and heat resistance compared to mild steel. Machinability varies by grade and hardness.

Good for:

Why customers love it: “Offers significantly improved strength, hardness, and wear resistance over mild steel, making it suitable for more demanding mechanical applications.”

Brass (Common Grades: C360, C260) An alloy of copper and zinc, known for its excellent machinability, good corrosion resistance, electrical conductivity, and attractive gold-like appearance. It offers low friction properties.

Good for:

Why customers love it: “It machines incredibly easily, looks great, resists corrosion well, and is perfect for intricate parts, fittings, and decorative applications.”

Copper (Common Grades: C101, C110) Valued primarily for its exceptional electrical and thermal conductivity. It’s also corrosion-resistant and relatively easy to machine, though it can be ‘gummy’. Often used in its pure form or alloys.

Good for:

Why customers love it: “Its unmatched electrical and thermal conductivity makes it the go-to material for applications involving efficient transfer of electricity or heat.”

Titanium (Common Grades: Grade 2, Grade 5 / Ti-6Al-4V) Offers an exceptional strength-to-weight ratio, outstanding corrosion resistance (especially to saltwater and chemicals), biocompatibility, and high-temperature performance. It is challenging and more costly to machine.

Good for:

Why customers love it: “It’s incredibly strong yet lightweight and virtually immune to corrosion, making it essential for critical applications in aerospace, medical, and other demanding fields despite the machining challenges.”

Plastics

ABS (Acrylonitrile Butadiene Styrene) A common thermoplastic known for its good impact resistance, toughness, rigidity, and ease of machining and finishing (can be glued, painted, sanded). Cost-effective.

Good for:

Why customers love it: “ABS is a versatile, tough, and affordable plastic that’s easy to work with, making it great for prototypes, enclosures, and many general-purpose parts.”

Polycarbonate (PC) An engineering thermoplastic valued for its extremely high impact strength (toughness), good temperature resistance, and optical clarity (in specific grades).

Good for:

Why customers love it: “Its incredible toughness and clarity make it ideal for applications needing high impact resistance, like protective guards and durable transparent parts.”

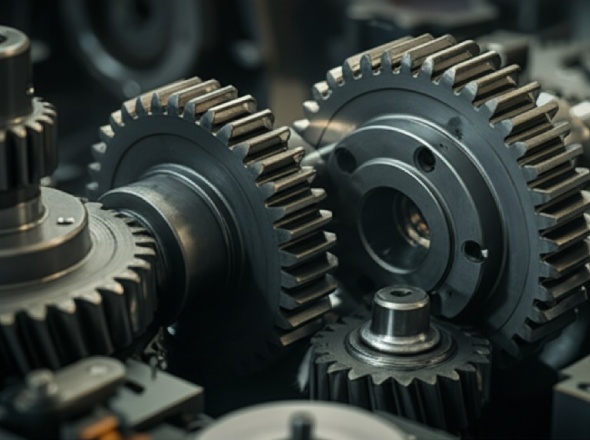

Nylon (PA) (Common Types: Nylon 6, Nylon 6/6) An engineering thermoplastic known for good toughness, wear resistance, chemical resistance, and relatively low friction (especially when filled). It tends to absorb moisture, which can affect dimensional stability.

Good for:

Why customers love it: “Nylon offers excellent wear resistance and toughness, making it a durable choice for moving parts like gears and bushings, especially where lubrication is limited.”

Acrylic (PMMA) Known for its excellent optical clarity, weather resistance, and rigidity. It’s relatively brittle compared to PC but machines well with sharp tools to achieve a polished finish.

Good for:

Why customers love it: “Its glass-like clarity and ease of achieving a high-quality finish make it perfect for visual applications like displays, signs, and transparent parts.”

PVC (Polyvinyl Chloride) A widely used thermoplastic offering good chemical resistance, electrical insulation properties, durability, and low cost. Can be rigid or flexible. Machinability is fair; requires care to avoid melting.

Good for:

Why customers love it: “PVC is a cost-effective and durable plastic with excellent chemical resistance, making it suitable for various industrial, construction, and electrical applications.”

PEEK (Polyether Ether Ketone) A high-performance engineering thermoplastic with exceptional mechanical strength, stiffness, chemical resistance, wear resistance, and performance at high temperatures. It is relatively expensive.

Good for:

Why customers love it: “When extreme temperature, chemical resistance, and mechanical strength are required, PEEK delivers outstanding performance, justifying its cost for critical applications.”

Other

Carbon Fiber Reinforced Polymer (CFRP) Composed of carbon fibers embedded in a polymer matrix (typically epoxy). Offers an exceptionally high stiffness-to-weight and strength-to-weight ratio. Machining is abrasive and produces hazardous dust, requiring specialized tooling and extraction.

Good for:

Why customers love it: “It provides incredible strength and stiffness at a fraction of the weight of metals, enabling performance gains in aerospace, automotive, and robotics.”

Fiberglass (GFRP) (Glass Fiber Reinforced Polymer) Consists of glass fibers in a polymer matrix. Offers good strength, stiffness, durability, and corrosion resistance at a lower cost than carbon fiber. Also abrasive to machine.

Good for:

Why customers love it: “Fiberglass provides a great balance of strength, durability, and cost-effectiveness for large structures and parts needing good corrosion resistance.”

G10 / FR-4 A high-pressure thermoset laminate made from woven fiberglass cloth and an epoxy resin binder. Known for high strength, low moisture absorption, excellent electrical insulating properties, and good dimensional stability. Abrasive to machine.

Good for:

Why customers love it: “It’s a very strong, stable, and non-conductive material, perfect for robust electrical insulation applications, jigs, and structural parts where moisture is a concern.”

Hardwoods (Examples: Oak, Maple, Walnut, Cherry) Wood from deciduous trees. Generally denser, harder, and more durable than softwoods, offering attractive grain patterns. Machinability varies by species.

Good for:

Why customers love it: “Hardwoods offer natural beauty, strength, and durability, making them ideal for high-quality finished products, detailed carvings, and robust fixtures.”

Softwoods (Examples: Pine, Cedar, Fir) Wood from coniferous trees. Generally lighter, softer, and less expensive than hardwoods. Easier to machine but more prone to denting and splintering.

Good for:

Why customers love it: “Softwoods are typically more affordable and easier to machine than hardwoods, making them great for prototyping, pattern making, and less demanding applications.”

MDF (Medium-Density Fiberboard) An engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining them with wax and resin, and forming panels under high temperature and pressure. It’s dense, uniform, stable, and has a smooth surface ideal for painting. Heavy and poor moisture resistance.

Good for:

Why customers love it: “MDF machines very smoothly with no grain, provides excellent dimensional stability, and has a perfect surface for painting, making it ideal for patterns, painted parts, and stable fixtures.”

Ready to get the perfect parts for your robot project? Here’s how:

Contact us today to learn more about our robot machining services or to get a quote for your project!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or