Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for custom rubber parts that fit just right? Our precision CNC machining service can make exactly what you need! We cut, shape, and finish rubber parts with amazing accuracy. Read on to learn how we can help with your rubber part needs.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

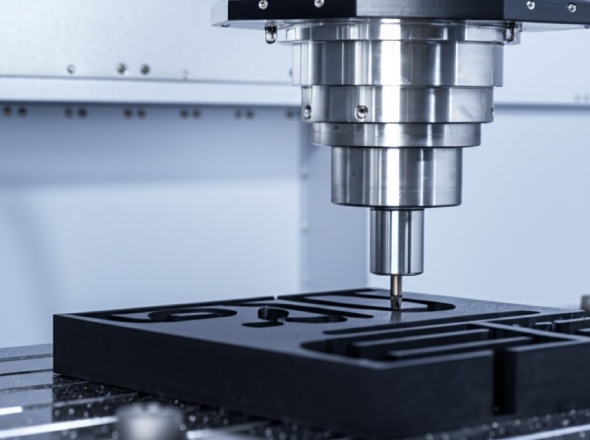

Rubber CNC machining uses computer-controlled tools to cut and shape rubber materials. This gives you parts that are:

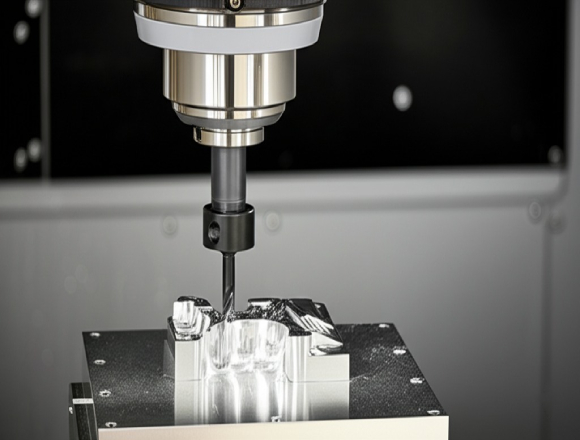

At Istar Machining, we use multi-axis CNC technology to create complex rubber parts that simply wouldn’t be possible with basic cutting tools.

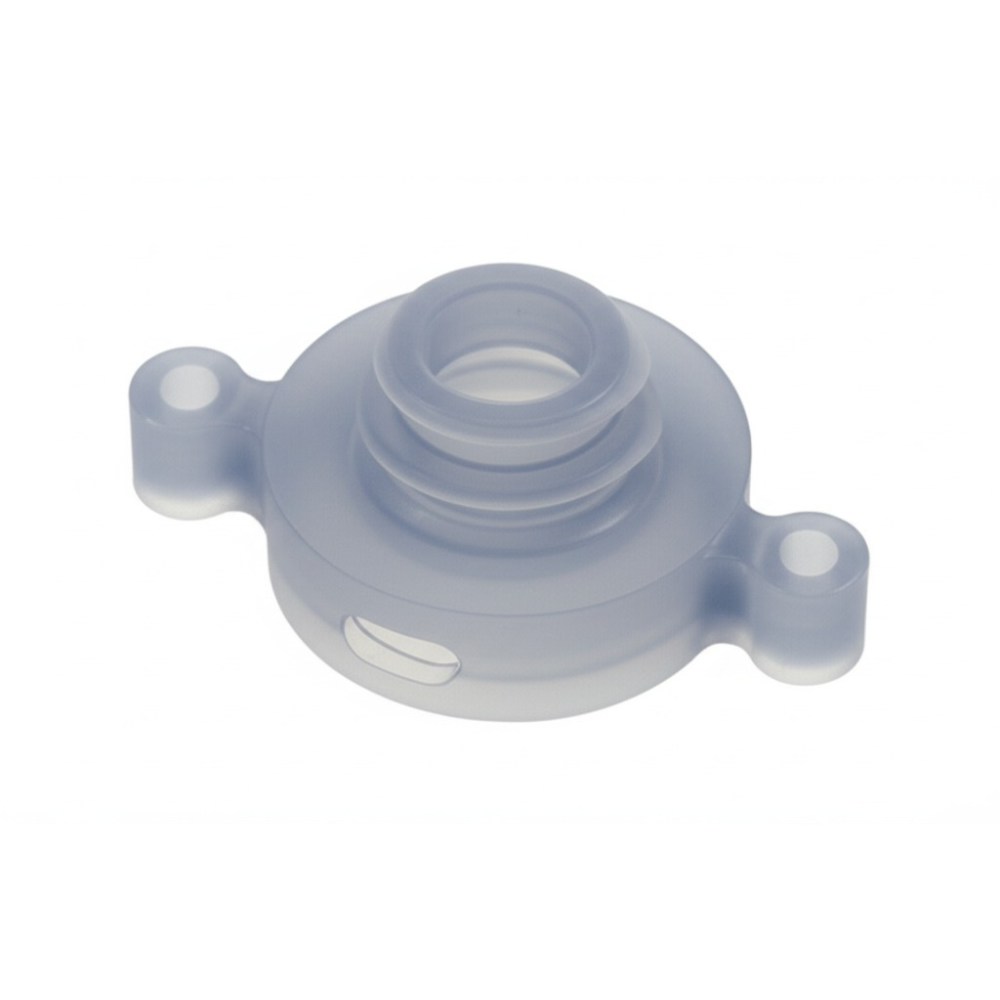

Our CNC machining capabilities extend to a variety of rubber materials, allowing for the precise creation of custom parts like seals, gaskets, pads, rollers, and prototypes. The choice of material depends heavily on the application’s requirements for chemical resistance, temperature range, abrasion resistance, and flexibility.

Here are some of the common rubber materials we can CNC machine:

General Purpose & Widely Used Rubbers

High-Performance & Specialty Rubbers

Foam & Sponge Rubbers

Our CNC rubber cutting process follows these steps:

We help you pick the right rubber for your needs

We create or use your 3D design file

We plan the best way to cut your part

Our machines precisely cut the rubber

We smooth edges and check the part

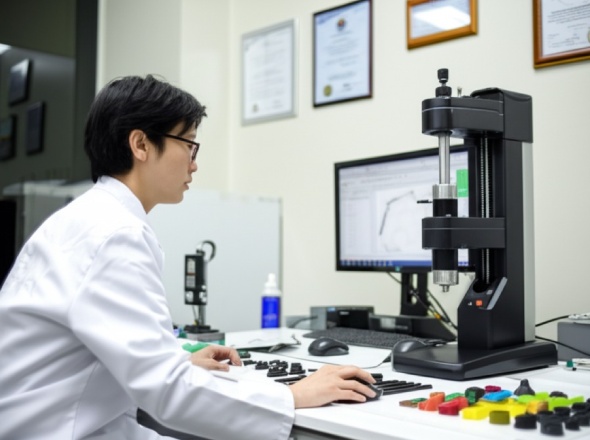

We make sure everything meets your needs

Our CNC machines can make rubber parts within ±0.005″ of your specifications. That’s about the thickness of a human hair! This makes our parts perfect for:

We work with rubber in many hardness levels (from soft 20A to firm 90A Shore hardness). This means we can make:

We can make rubber parts up to 24″ x 12″ x 8″ in size. Whether you need tiny O-rings or large industrial seals, we’ve got you covered!

Our CNC milling rubber service makes parts for many industries:

There are several ways to make rubber parts. Here’s why CNC machining is often the best choice:

Method | Advantages of CNC |

Injection Molding | No expensive molds needed – save money on small runs |

Die Cutting | Can create complex 3D shapes, not just flat parts |

Hand Cutting | Much more precise and repeatable |

3D Printing | Better material properties and durability |

A medical device company needed special silicone seals that could stand up to sterilization. The parts had complex shapes with tiny grooves. Traditional methods couldn’t make these parts with enough precision.

Our solution: Using our 5-axis machining technology, we created perfect silicone seals that:

The result? The company’s devices worked better and lasted longer!

Here’s what our rubber CNC machining can do:

We’re not just any machine shop. We’re experts in rubber CNC machining with:

Getting custom rubber parts is easy with Istar Machining:

Don’t settle for rubber parts that almost fit. Get exactly what you need with our custom CNC machining services!

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or