Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Have you ever wondered what makes a steel beam so strong? Or what makes a rubber band so stretchy? A big piece of the answer is something called the shear modulus. In all my time working with different materials, I have seen just how important this one number can be. It tells us how a material will handle forces that try to twist it or make its layers slide.

Learning about shear moduli is very important for building safe bridges and making better products. It even helps us understand the world we live in. This article will explain everything you need to know about this important modulus. I will use simple words so you can understand why it is so important and how it is a part of your daily life. It is worth your time to read this because knowing about shear moduli will help you understand the strength and stiffness of the materials that make up our world.

People often ask me to explain shear moduli in a simple way. Here is a good way to think about it. The shear modulus is a way to measure how stiff a material is when a force tries to make its layers slide past each other. Picture a thick book. If you hold the bottom cover still and push the top cover to the side, you will feel the book push back. That push back, or resistance, is related to the material’s shear modulus. This property is also called the modulus of rigidity. The higher the shear modulus is, the more a material fights against this sliding. This change in shape is called deformation. This modulus is a very basic part of a material’s elastic properties.

The official definition is that the shear modulus is defined as the ratio of shear stress to shear strain. Let me explain those words. “Stress” is the amount of force you use over a certain area. “Strain” is how much the material bends or changes shape. So, the shear modulus tells us how much stress you need to get a certain amount of strain. This is a very important idea for understanding the elasticity of materials. This modulus is a measure of the material’s power to go back to its original shape after you stop the force. This is why it is very, very important for engineers and scientists to understand shear moduli. It helps them guess how materials will act in everyday situations. It is one of the needed elastic constants they use.

This modulus is one of the most important ways to check a material’s strength and how it acts. The shear modulus value indicates how well a material resists a change in shape from shearing. A material with a high shear modulus is very stiff or hard to bend. A material with a low shear modulus is very flexible. This value is part of a group of elastic moduli. It is very important for designing all kinds of things, from tall buildings to parts for cars. A building’s power to hold up against pushes and pulls from something like the wind often comes from the shear moduli of its parts.

Now, let’s look at the math for this modulus. The shear modulus equation is pretty easy to understand. The equation looks like this:

G = τ / γ

Here is what the letters in that equation mean:

Shear stress is the push or pull that goes along the top of a surface, divided by the size of that surface. Shear strain is the amount the material changes shape, or the amount of deformation. The shear modulus equation shows that the modulus is defined by this simple relationship. This ratio of stress to strain is a basic idea in the science of materials.

The main unit used by scientists for the shear modulus is the Pascal (Pa). A pascal is a measure of pressure, which is a force put on an area. But materials are usually very strong, so their shear moduli are huge numbers. Because of this, we usually expressed the numbers in gigapascals (GPa). A gigapascal is one billion Pascals! You might also see it written in pounds per square inch (psi). When we measure the shear modulus, we are finding this important number for a material. This shear modulus model is a key part of how we study linear elastic materials.

Through my work, I have used many different materials. Their shear modulus values can be very different from each other. This shows how different their stiffness can be. A material with a high shear modulus is very stiff. A material with a low shear modulus is very bendy. For example, diamond is super stiff, so it has one of the highest shear moduli. But a soft material like rubber has a very low one. A material with a shear modulus of zero is a liquid, because it does not fight against shearing at all.

Here is a table with some common shear modulus values. It can help you get a better picture of this modulus. You can see that a hard metal like steel has a much higher modulus than a softer material like a polymer. This information is very helpful when you need to pick the right material for a job. For example, materials with a shear modulus below 10 GPa are seen as being quite flexible. Materials with shear moduli of 40 GPa or lower are used when some bending is okay.

| Material | Shear Modulus (G) in GPa |

|---|---|

| Diamond | 478 |

| Steel | 79.3 |

| Copper | 48 |

| Aluminum | 25 |

| Glass | 26-32 |

| Polycarbonate (Polymer) | 0.8 |

| Rubber | 0.0006 |

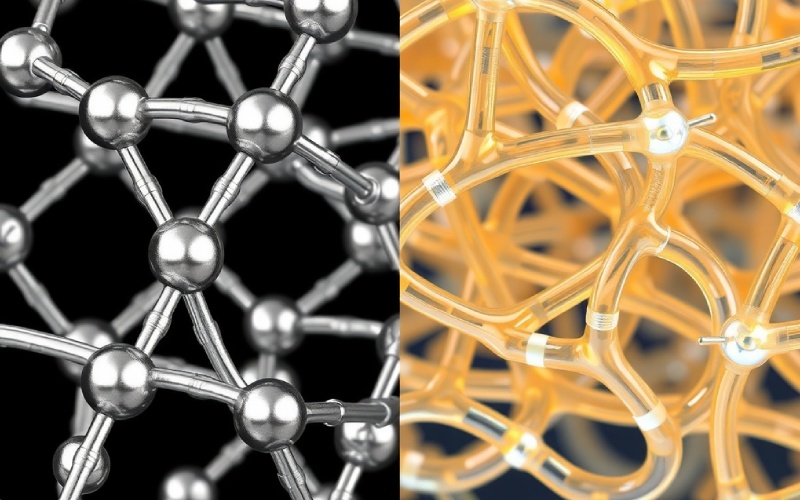

As you can see, the shear moduli can be extremely high or very low. Diamond has the highest shear modulus and is incredibly stiff. This is because of the very strong connections between the tiny particles inside the diamond’s diamond cubic crystal structure. This table helps show why steel is chosen for the frames of buildings and why rubber is used to make tires.

From my experience in building design, the shear modulus of a metal is one of the most important things we think about. When we design buildings and bridges, we have to think about all the forces they will have to handle. These forces can cause pushing and sliding forces, called shear stresses in the steel parts of a building. For example, a strong wind pushing on the side of a tall building makes a very strong sideways push, which is a shear force. This force causes a deformation caused by shear forces. We need to be sure the building can handle that change in shape without breaking.

The structural steel used for building has a high shear modulus, about 79.3 GPa. This high value means it has a great resistance to deformation from these sideways forces. The stiffness of a material like steel is the reason it is used as the backbone for our modern cities. If steel did not have a high modulus of rigidity, buildings would twist and move in a very dangerous way. We must carefully figure out the stresses in the steel members to make sure they can bounce back to their original shape. This is why knowing the shear moduli of different kinds of metal is so important.

When builders pick materials, the modulus is a very important thing to check. The shear modulus indicates how a material will act when twisting forces, or twisting stresses on the structure, are put on it. A high modulus makes sure that the deformation of a solid is very small when it is being pushed or pulled. This is why the stiffness of a solid is a top worry for any building project. We want to control the strain under shear forces to keep our buildings safe.

Polymers are very interesting because they act so differently from metals. When we talk about shear moduli, the difference is huge. As you saw in the table, a polymer like polycarbonate has a shear modulus that is less than 1 GPa. Now, think about steel, which is almost 80 GPa! This is because the tiny parts of a polymer are linked together in long chains with weaker connections. In a metal, the connections are much stronger. This makes a polymer much more flexible and not as stiff as a metal.

This low shear modulus is not always a bad thing. It just means that polymers are good for different jobs. Think about a plastic bottle or a nylon rope. They are flexible because of their low modulus. That is what makes them useful. We do not want a plastic bottle to be as stiff as a steel beam. The modulus of a polymer lets it change shape a lot without breaking. This is a kind of elasticity. This material’s response is perfect for many products we use every day.

Engineers use these different shear moduli to their advantage. If they need something to be very stiff, they will choose a metal. If they need it to be flexible and able to soak up bumps, they will often use a polymer. The choice is all about what the material needs to do. The low shear modulus of a polymer means it is more easily affected by shear forces, or more susceptible to shear. But this is often what we want. Understanding the big difference in shear moduli between these types of materials is very important for making good designs.

Sometimes you might hear the word isotropic when people talk about materials. It is an easy idea, but it is important. An isotropic material is the same and acts the same no matter which way you look at it or test it. Think about a solid block of steel. If you check its shear modulus from the top, from the side, or from the front, you will get the same number every time. Most common metals, like steel and aluminum, are seen as being isotropic.

Because it is the same in all directions, the math is much simpler for engineers. When you know a material is isotropic, you only need to find its shear modulus one time. That same number will work no matter how the force pushes on the material. This makes it much easier to study things like in-plane shear and other tricky forces.

But not all materials are this way. Wood is a good example of a material that is not isotropic. Its strength is different if you test it along the grain versus across the grain. These materials are called anisotropic, meaning their strength is different in different directions. For isotropic materials, the elastic constants, which include the shear modulus and Young’s modulus, are the same in every direction. This makes it much easier to know how they will act when they are under stress.

How a material acts is not always the same. Pressure and temperature can really change a material’s shear modulus. Usually, when you heat a material up, its shear modulus goes down. Think about heating up a piece of metal. It gets softer and easier to bend. This is because the heat makes the tiny particles inside jiggle around more. This makes it easier for them to slide past each other, which makes the material less stiff.

The opposite happens with pressure. Squeezing a material usually makes its shear modulus go up. The high pressure pushes its tiny particles closer together. This makes it harder for them to move. This is very important for scientists like geologists. They study how rocks act deep inside the Earth, where there is huge pressure and temperature.

These changes are why the details for a material often tell you the pressure and temperature that were used when its shear modulus was measured. For most everyday jobs at normal pressure and temperature, we can use the normal values. But for special jobs, like making airplanes or things that go deep in the ocean, we have to think about how the world around them will change the shear moduli of the materials. The modulus is determined under certain conditions for this very reason.

The idea of a shear wave is a great way to understand the shear modulus. A shear wave, which is also called an S-wave, is a kind of wave that can move through solid things. Think about shaking a long rope up and down. A wave moves down the rope, but the rope itself is just moving up and down. It moves at a right angle to the direction the wave is moving. This is how a shear wave moves through a solid. The tiny parts of the solid move back and forth, but not in the same direction that the wave is going.

Here is the connection. How fast a shear wave moves is directly linked to the material’s shear modulus and how heavy it is for its size (its density). If a material has a higher shear modulus, the shear wave will move faster. This happens because a stiffer material (with a higher modulus) bounces back faster. This lets the wave’s energy travel through it more easily. This fact is used by scientists who study earthquakes, called seismologists, to learn about what’s deep inside the Earth. By checking the speed of earthquake S-waves, they can learn about the shear moduli of the rocks far below us.

This is a very smart way to use our knowledge of shear moduli. It lets us “see” inside our planet. It is a good reminder that this simple modulus is not just a number on a page. It is a real property that controls real things, like how a shear wave moves. Liquids can’t have shear waves because they have a shear modulus of zero.

When you learn about how materials work, people sometimes mix up Young’s modulus and the shear modulus. They both are types of elastic moduli. This means they both measure how stiff a material is. But they tell us about stiffness against different kinds of pushes and pulls. The modulus and shear modulus describe different actions. Let me explain the difference.

Young’s modulus is also called the modulus of elasticity. It measures how much a material fights against being pulled apart or squished together. It has to do with a tensile or compressive force. This is a force that pulls or pushes in only one direction, like straight out or straight in. This is called uniaxial stress. If you pull on a wire, Young’s modulus is a measure of how much it fights the stretch. We can calculate Young’s modulus by doing tests where we pull on materials.

The shear modulus, as we have talked about, measures how much a material fights against shearing or twisting. It describes the material’s response to shear stress, where the forces are moving along the material’s surface. So, they both measure stiffness. But Young’s modulus is for pulling and pushing in one line. The shear modulus is for shearing and twisting. For isotropic materials, these two moduli are linked together by another measurement called Poisson’s ratio.

Last, let’s link the shear modulus to a very basic rule in science called Hooke’s Law. You might remember Hooke’s Law from school. The law says that the more you stretch a spring, the more force it takes. Looking at it in a broader way, Hooke’s Law tells us that for an elastic material, the amount of stress is directly tied to the amount of strain.

The shear modulus is basically the special number in Hooke’s Law that we use for shearing forces. The shear modulus equation (G = τ / γ) is just a version of Hooke’s Law that we use for shear stress and shear strain. It tells us that for a linear elastic material, the connection between shear stress to shear strain makes a straight line on a graph. The steepness of that line is the shear modulus.

This is why the idea of elasticity has been so important in our talk. The shear modulus only tells us how a material acts when it is elastic. This means it is in the zone where it will go back to its old shape after the force is gone. If you use too much shear force and the material bends for good, then Hooke’s Law doesn’t work anymore. This link shows that shear moduli come from the basic rules of how materials deform, or change shape.