Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

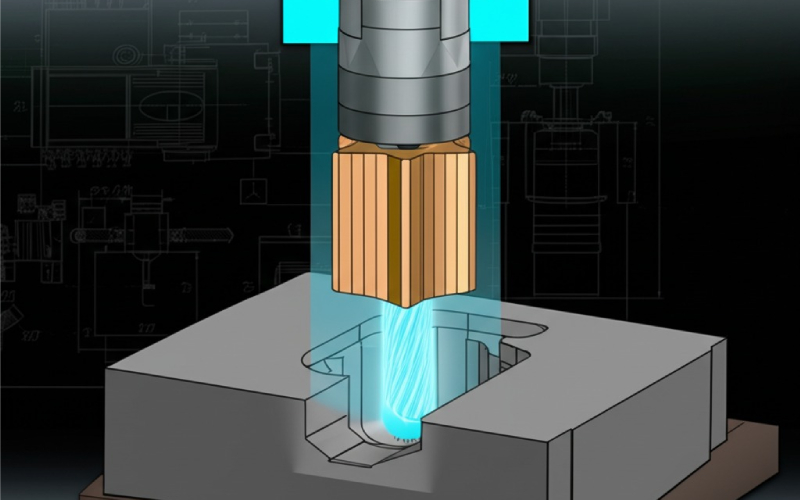

Are you looking for super-precise cutting for your tough metals? Sinker EDM machining from Istar Machining is the answer! This special way of cutting can make complex shapes in the hardest metals. Let’s explore what makes it so amazing and how it can help with your projects.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Think of sinker EDM like using a cookie cutter, but with electricity! Here’s how it works:

The best part? This works on super hard metals that regular cutting tools can’t handle!

Our sinker EDM process works with many tough metals:

From common alloys to the toughest hardened tool steels, Sinker EDM provides precision and excellent surface finishes.

Carbon Steels: (e.g., 1018, 1045)

Alloy Steels: (e.g., 4140, 4340)

Tool Steels: (Crucial for EDM; Ideal for molds, dies, and high-wear components)

Stainless Steels: (All conductive series)

Pre-hardened Steels: (e.g., P20, H13 hardened condition)

Case Hardened Steels: (After hardening)

Lightweight, versatile, and easily processed using Sinker EDM for various applications.

Common Wrought Grades: 6061, 7075, 2024, 5052

Tooling Plate: MIC-6, Alca-5

Cast Aluminum Grades: (e.g., A356, A380)

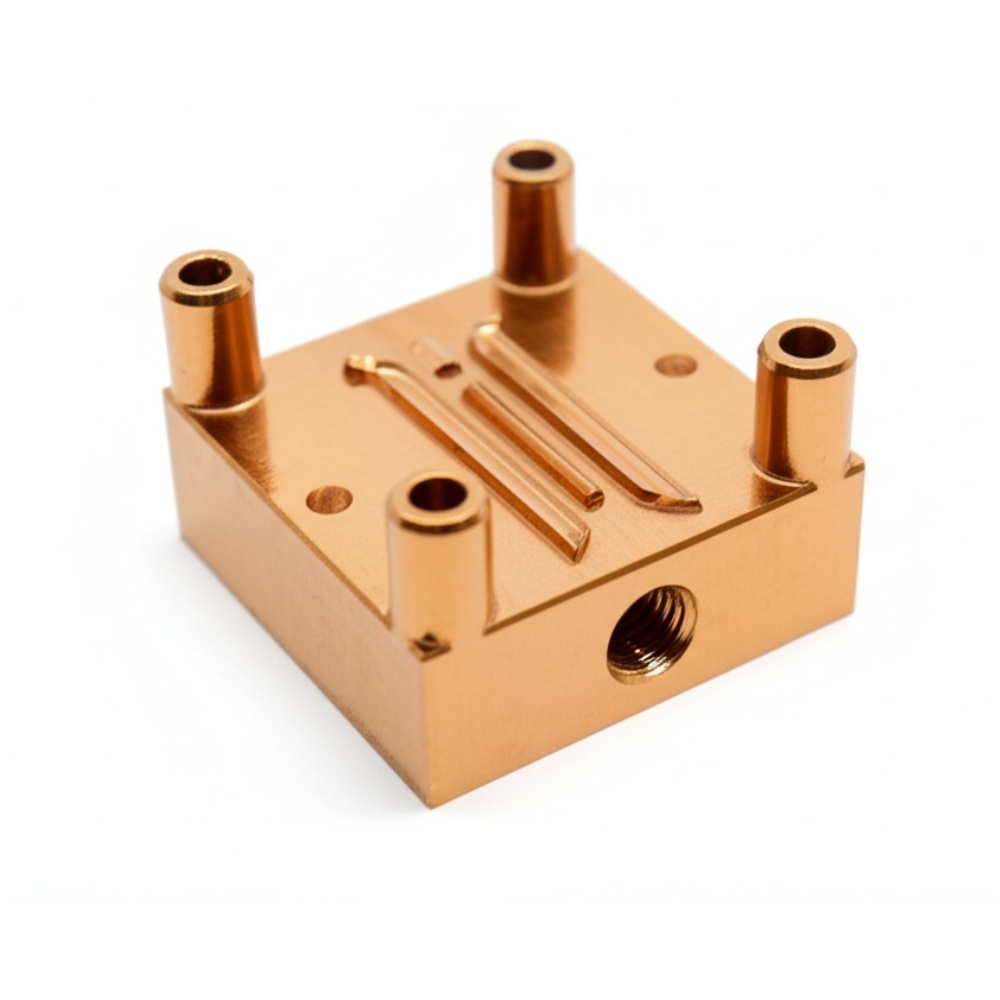

Excellent electrical conductivity makes copper and its alloys suitable workpieces, often used in electrical and thermal applications.

Copper: C101 (OFE/OFHC), C110 (ETP)

Brass: C360 (Free-Cutting Brass)

Bronze: C932 (Bearing Bronze), C954 (Aluminum Bronze)

Beryllium Copper (BeCu): C172, C173 (Often used for mold inserts requiring high strength and thermal conductivity)

Known for high strength-to-weight ratio, biocompatibility, and corrosion resistance; often challenging for conventional methods but ideal for Sinker EDM.

Commercially Pure (CP): Grade 1, Grade 2, Grade 4

Alpha-Beta Alloys: Grade 5 (Ti-6Al-4V) – Most common

Beta Alloys: (Various grades)

High-performance alloys designed for extreme temperature, pressure, and corrosive environments. Sinker EDM effectively handles their inherent toughness.

Inconel®: 625, 718, X-750

Hastelloy®: C276, C22, X

Monel®: 400, K500

Waspaloy®

Rene Alloys (e.g., Rene 41)

Extremely hard and wear-resistant materials where Sinker EDM is often the only viable machining method for creating complex shapes or features.

Tungsten Carbide (WC)

Cemented Carbides (Various Cobalt or Nickel binder grades)

We have experience machining materials with unique properties like very high melting points, density, or extreme hardness.

Tungsten (W)

Molybdenum (Moly)

Tantalum (Ta)

Niobium (Nb) (also known as Columbium)

Cobalt Chrome (CoCr) (e.g., ASTM F75, F1537 – often used in medical implants)

Product Parameters | What It Means For You |

Power Supply: 30-50A (rough cutting), 3-10A (finishing) | We can cut fast for rough shapes, then switch to super-precise finishing |

Electrode Materials: Graphite, Copper-Tungsten, Brass | We choose the perfect electrode for your project’s needs |

Orbital Machining: 0.1-3mm offset control | We can make undercuts and complex angles that other methods can’t |

Dielectric Fluids: Hydrocarbon oil, Deionized water | The right fluid ensures clean, precise cuts on your specific metal |

Surface Finish: Ra 0.8–3.2 µm | Get surfaces smooth enough to use with minimal polishing |

Precision: ±0.0001″ (2.5µm) | Parts that fit perfectly every time |

At Istar Machining, we help many different industries with our sinker EDM services:

We make perfect die components and transmission gears that last longer and perform better. Want to learn more? Check out our automotive CNC machining page.

Our sinker EDM process creates the tiny, complex parts needed for biocompatible implants and microfluidic devices. We maintain strict cleanliness standards for all medical parts.

Fuel nozzles and heat-resistant shrouds for jet engines need to be perfect. Our aerospace EDM services meet or exceed all industry standards.

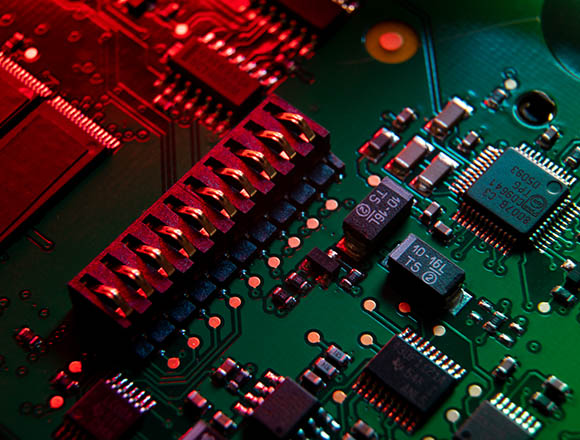

We make perfect injection molds for tiny connectors and electronic housings. These molds create consistent parts for millions of cycles.

Sinker EDM is perfect for many different industries. At Istar Machining, we help customers with:

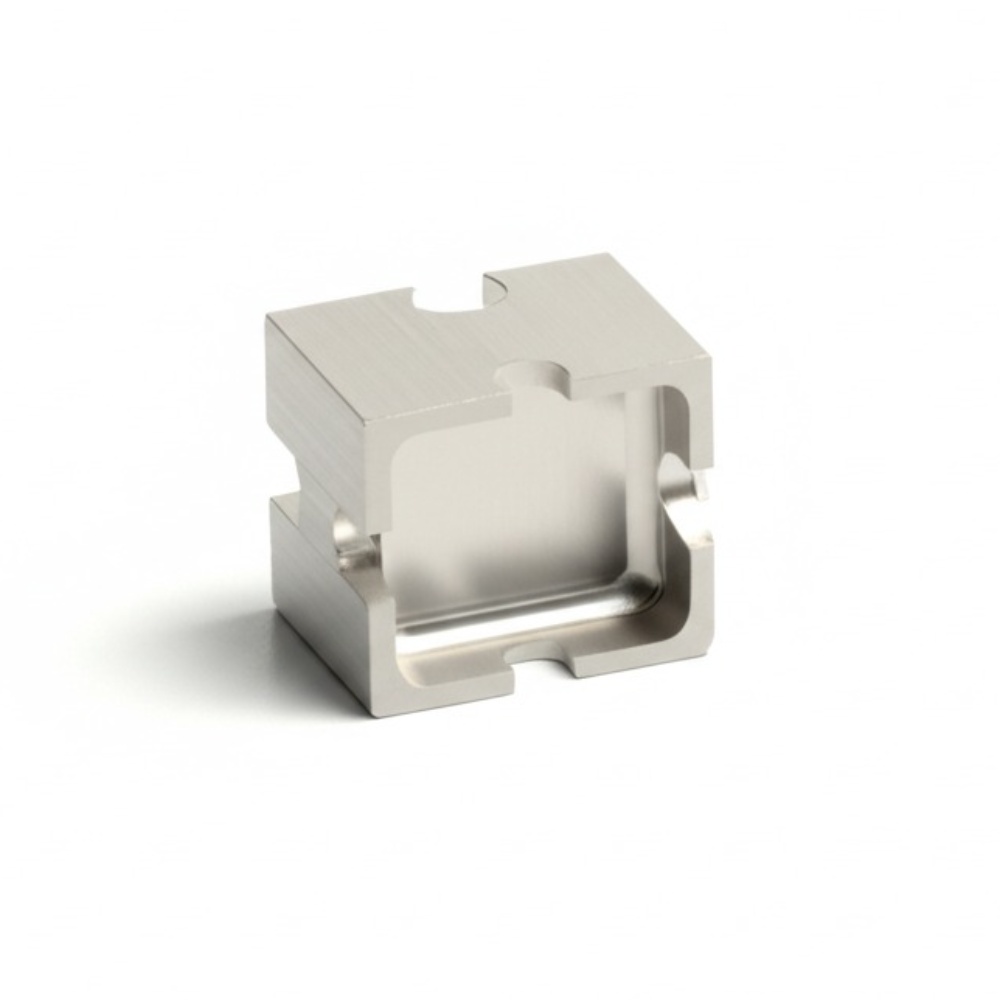

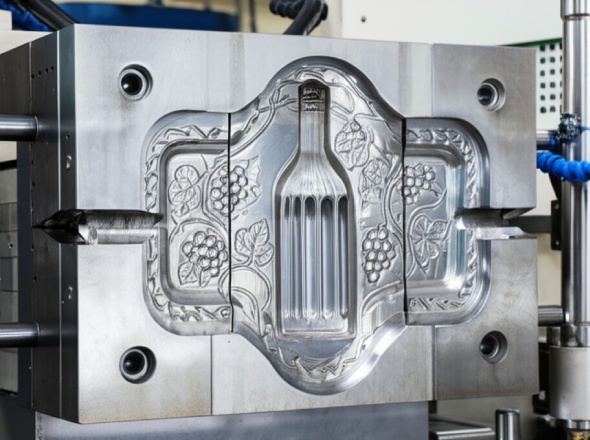

Mold & Die Manufacturing

We make perfect molds for plastic injection, metal stamping, and forging. Our precision CNC machining service paired with sinker EDM creates flawless molds that last longer.

Aerospace Components

Aerospace parts need to be perfect. We make turbine blades and fuel system parts that meet the strictest standards. Our ±0.0001″ tolerances mean parts that fit perfectly every time.

Medical Devices

For medical tools and implants, we create the tiny, complex shapes doctors need. Our clean processes ensure parts meet all health standards.

Tiny Holes Without Threads

We can make super small holes (as small as 0.008″ wide) without damaging the metal. This is great for precision parts and microfluidic devices.

Fixing Old Tools

Have an old die or mold that’s worn out? We can use sinker EDM to fix it without making a whole new one – saving you money!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our advanced machines can control the spark gap and orbital paths to create undercuts and complex angles that other shops simply can't make.

We can mix sinker EDM with our wire EDM machining and CNC milling for multi-feature parts that would be impossible to make any other way.

Our adaptive flushing systems reduce cutting time by 25% compared to standard methods. This means you get your parts faster without sacrificing quality.

We have partners who provide certified aerospace and medical-grade alloys. This means we can help you choose the right material for your project.

We follow ISO 9001 standards and provide full documentation of your parts. You'll know exactly what you're getting.

We look at your design to make sure it's perfect for EDM.

We carefully create the electrode that will shape your part.

We make sample cuts to verify dimensions before full production.

Your parts are made with constant monitoring for quality.

Every part is checked against your specifications.

Sinker EDM (also called Ram EDM or Die-Sinking EDM) is a thermal erosion process that uses electricity to cut metal. It doesn’t touch the metal directly. Instead, it creates tiny sparks that melt away small bits of metal.

Different projects need different electrodes:

Sinker EDM is best for making deep cavities and blind holes. Wire EDM works better for cutting all the way through material in 2D shapes. At Istar Machining, we often use both methods on complex parts.

Yes! We use powder additives in our dielectric fluid that can reduce roughness by 50%. This means less hand finishing later.

We make multiple electrodes at once and use automated tool changers to keep costs down. Let us know your budget, and we’ll find ways to help you save.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or