Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

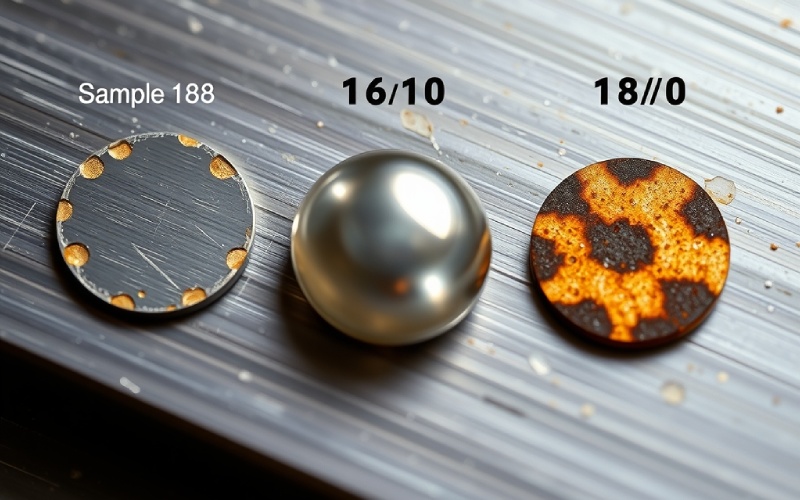

There’s a big difference in what we call “stainless steel.” Those small numbers you see on the back of a fork or spoon—18/8, 18/10, 18/0—are not just for looks. They tell you about the quality, how long your flatware will last, and even how shiny it is.

This article is for anyone who has ever seen those numbers and wondered what they mean or why they are important. I will explain what these common types of stainless steel are made of, tell you how those differences change how they work, and help you pick the right grade of stainless steel for your house or company. We will look at what chromium and nickel do, learn about the small differences in how they fight corrosion, and even talk about how these metal mixes are made. When you finish reading, you’ll be able to choose the best flatware for what you need, knowing all the important details.

When you see “18/8,” “18/10,” or “18/0” on stainless steel flatware, it’s a short way of showing the amount of chromium and nickel in the steel mix. The first number, 18, always means the amount of chromium—which is 18%. Chromium is the main ingredient that makes steel “stainless.” It makes it hard and, most importantly, helps it fight against rust and corrosion. The second number tells you the amount of nickel in the flatware. So, 18/8 stainless steel has 18% chromium and 8% nickel, 18/10 has 18% chromium and 10% nickel, and 18/0 has 18% chromium and 0% nickel.

Nickel is a very important and costly part of the mix that makes the steel much better. It adds even more corrosion resistance, especially against sour or acidic foods, and it gives the steel a nice, bright shine like silver. The amount of nickel is the main thing that makes these three popular choices of steel different. It changes everything from how long it lasts to how it looks and, of course, how much it costs. Knowing what they are made of is the first step to seeing the small but important differences between these three types of steel in your daily utensil.

I have learned that 18/8 stainless steel is a very useful material that is used in many places, especially in kitchens. This type of stainless steel contains 18% chromium and 8% nickel. It is also known as 304 stainless steel and is often chosen for things that touch food. The 8% nickel gives it good corrosion resistance, which makes it good for many uses, like flatware, pots and pans, and even some kitchen appliances. This grade of steel is strong enough for daily use and can handle the heavy use of a restaurant kitchen.

You will often see 18/8 steel in flatware and cookware that is not the cheapest but not the most expensive. It offers a good mix of quality and price. This grade of stainless steel is also a common pick for many things around the house and even in building construction. While it fights off corrosion well, its shine might not be as bright as 18/10 steel. But for most daily needs, the strength and corrosion resistance of 18/8 steel make it a great and dependable choice for your fork, spoon, and knife.

In my work, when a client wants to show that a product is fancy and high-quality, they often use 18/10 stainless steel. This grade of steel has 18% chromium and 10% nickel, and that extra 2% of nickel makes a difference you can see. The higher amount of nickel gives 18/10 flatware a better shine and gloss, making it look a lot like real silver. This premium grade of flatware is often said to have a bright, long-lasting shine. Because of this, it is the top pick for nice restaurants and hotels that want their tables to look elegant.

Besides looking great, the extra nickel in 18/10 steel also gives it better corrosion resistance. It is very good at fighting off rust and stains, even when it touches acidic foods or strong soaps in the dishwasher. This extra strength means that 18/10 flatware is not only pretty but also made to last for a very long time if you take care of it. It is the most expensive of the three because it has more nickel, but many people think it’s worth the price for the better quality and long life it offers. This is the type of steel that feels very sturdy in your hand.

Sometimes, being practical and saving money are more important, and that’s when 18/0 stainless steel is a good choice. As you can guess from the name, this type of steel has 18% chromium and 0% nickel. Having no nickel makes it the cheapest of the three grades. This is a big help for places that use a lot of flatware, like school cafeterias, or for people who want a cheaper option for their home. Because it has no nickel, 18/0 flatware is magnetic. This is helpful for some restaurants that use magnets to stop their cutlery from being thrown away by mistake.

But not having nickel means there are some downsides. The biggest one is that it doesn’t fight corrosion as well as 18/8 and 18/10 steel. While you can usually put it in the dishwasher, it is more likely to get stains and rust, especially if you leave it wet for a long time. The shine of 18/0 steel is also not as bright as the kinds with nickel. Even with these issues, when saving money and having something that works are the main goals, 18/0 stainless steel flatware is still a popular and smart choice. This utensil is a workhorse, not just for show.

From my study of steel, I learned that nickel is the secret weapon when it comes to stopping corrosion. While chromium is the main thing that makes steel “stainless,” nickel makes this protection much better. Adding nickel helps the steel handle more types of corrosive things, especially acids. This is why steels with nickel are used not just in kitchens, but also in tough places like factories and on ships. The nickel helps make the protective top layer on the steel stronger and less likely to wear away.

The difference in corrosion resistance between 18/8 and 18/10 steel is small, but it can be important sometimes. The 10 percent nickel in 18/10 steel gives a little better protection from small pits and cracks that can be caused by salts found in some foods and water. For most use at home, 18/8 gives plenty of corrosion resistance. But for people who want the very best protection and long life, especially in wet places or with lots of contact with corrosive foods, the higher nickel in 18/10 steel gives that extra safety. The 18/0 steel, with no nickel, gives a more basic level of protection from corrosion.

Besides how well they fight corrosion and how shiny they are, there are other small but key differences between these three popular choices of steel. One of the main differences is in how they feel in your hand. Flatware made from 18/10 steel is often said to feel heavier and more solid, which many people connect with high-quality work. This is partly because nickel is denser. This extra heavy weight makes the utensil feel very sturdy and not likely to bend.

Another difference is in how they are made. All three are made by melting the different metals together. But because 18/8 and 18/10 steel have nickel, they belong to the “austenitic” group of stainless steels. This means they are usually not magnetic. In contrast, 18/0 steel is a “ferritic” stainless steel, which is magnetic. The different grades of stainless steel also last for different amounts of time, with 18/10 being the strongest and best at handling wear and tear over the years. These differences in the types of steel show why you should pay attention to the numbers on your flatware.

| Stainless Steel Grade | Chromium Content | Nickel Content | Corrosion Resistance | Shine | Magnetic? | Common Uses |

|---|---|---|---|---|---|---|

| 18/10 | 18% | 10% | Excellent | High | No | Fancy flatware, high-quality cookware. |

| 18/8 | 18% | 8% | Good | Good | No | Everyday flatware, cookware, kitchen appliances. |

| 18/0 | 18% | 0% | Fair | Moderate | Yes | Low-cost flatware, busy restaurants. |

A frequent question I heard when writing for my client was about whether their flatware was safe for the dishwasher. In general, all three grades—18/8, 18/10, and 18/0—are fine to put in the dishwasher. But how well they handle being washed over and over can be different. The high amount of nickel in 18/10 and 18/8 stainless steel makes them very good at resisting the strong soaps and high heat of a dishwasher. This means they are less likely to get water spots or marks and will keep their shine over time.

While 18/0 stainless steel can also be washed in a dishwasher, the fact that it has no nickel makes it more likely to get corroded and stained. You might find that 18/0 flatware needs a little more work to keep it looking nice, like making sure it’s totally dry after washing to stop rust spots. It’s always a good idea, no matter what grade of stainless steel you have, to not let flatware sit in a wet dishwasher for a long time. For people who want something that’s easy to care for and want their flatware to look perfect with little work, 18/10 or 18/8 stainless steel is the better pick.

Picking the best flatware for your home really depends on what you like, how much you want to spend, and how you will use it. If you want the very best in looks and how long it lasts, and you don’t mind spending more, 18/10 stainless steel flatware is the easy choice. Its great shine and corrosion resistance make it a beautiful and long-lasting option for both daily meals and special events. This is a premium grade of flatware that will last you for many years.

If you have a medium budget, 18/8 stainless steel gives you a great mix of quality and price. It’s strong, fights corrosion well, and has a nice shine, which makes it a very popular pick for many homes. It’s a dependable choice that will handle daily use and lots of washing in the dishwasher. If you need to save money or need a lot of flatware for a rental home or for big parties, 18/0 stainless steel is a fine option. It may not be as shiny or last as long as the other two grades, but it’s a useful and low-cost choice for a fork, spoon, or knife.