Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Welcome to Istar Machining’s guide to steel CNC machining! If you need strong, durable parts made with exact measurements, you’re in the right place. We make parts that work great in tough spots and last a long time.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Here’s why steel CNC machining stands out:

We work with many types of steel to match what you need:

What it is: A mix of steel with chromium and molybdenum

Good things:

Not so good things:

What it’s used for: Gears, shafts, car parts

Hardness: 28-32 HRC

What it is: Steel with lead added to make it easy to cut

Good things:

Not so good things:

What it’s used for: Nuts, bolts, small parts that need to be made fast

Hardness: 15-20 HRC

What it is: Steel with chromium and nickel that doesn’t rust

Good things:

Not so good things:

What it’s used for: Medical parts, food equipment, outdoor parts

Hardness: 20-25 HRC

316 stainless steel is even better for salt water and chemicals than 304.

What it is: Very hard steel used for making tools

Good things:

Not so good things:

What it’s used for: Cutting tools, dies, molds

Hardness: 58-62 HRC (very hard!)

What it is: Simple steel with low carbon

Good things:

Not so good things:

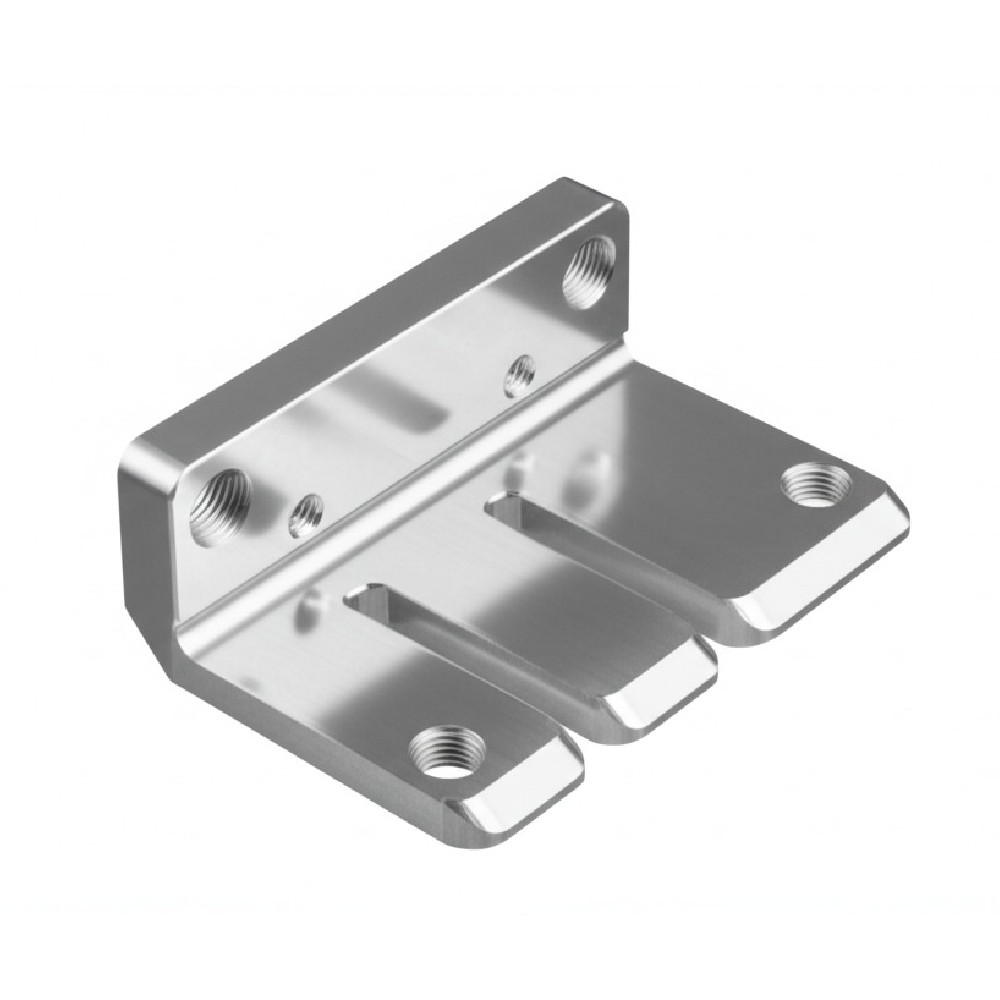

What it’s used for: Test parts, simple brackets, frames

Hardness: 15-22 HRC

What it is: Special stainless steel that can be heat treated

Good things:

Not so good things:

What it’s used for: Plane parts, medical tools, nuclear parts

Hardness: 35-45 HRC

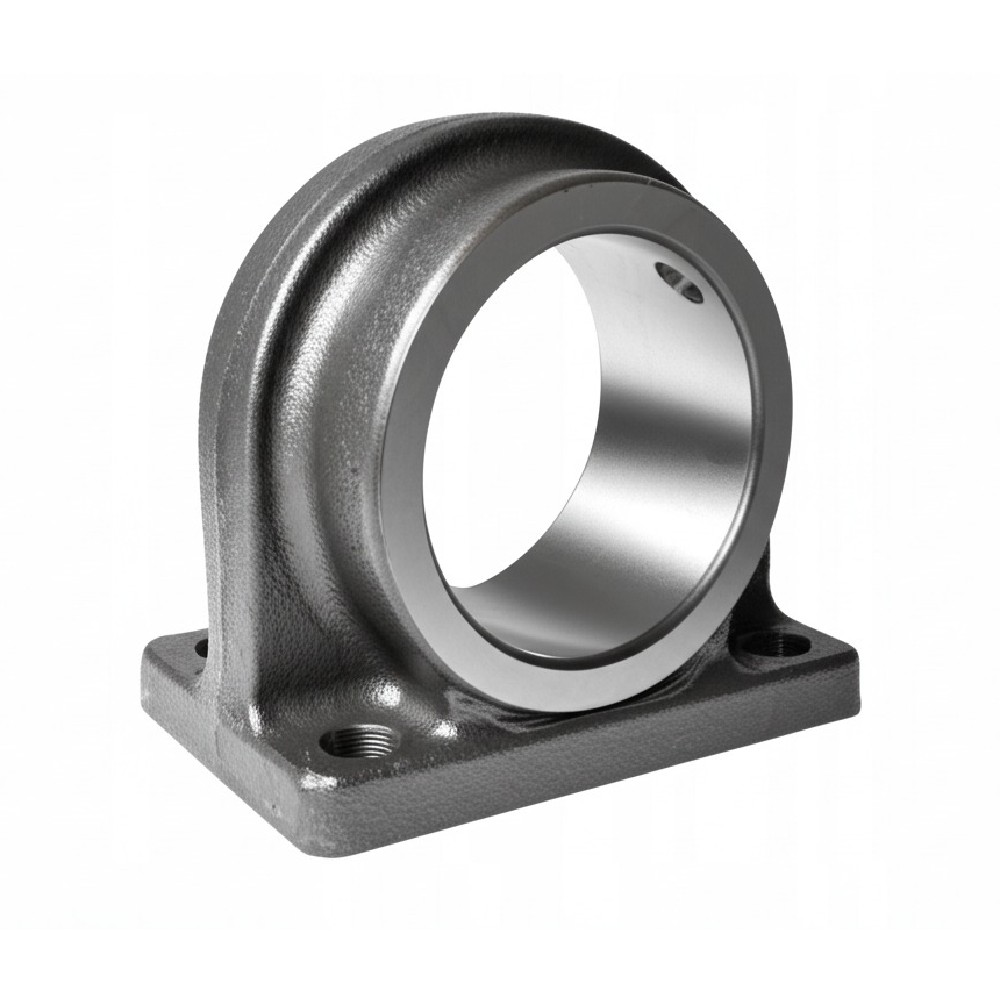

Our steel CNC machining helps many industries:

When choosing a company for your steel CNC needs, look for:

At Istar Machining, we offer all these benefits and more. Our team has years of experience making steel parts for all kinds of industries.

Here’s what our steel CNC machining can do:

Parameter | Capability | Best For |

Tolerance | ±0.005mm to ±0.1mm | Parts that must fit perfectly |

Surface Finish | Ra 0.4μm to 3.2μm | From mirror-smooth to textured |

Min/Max Size | 0.5mm to 2000mm | Tiny precision parts to large components |

Lead Time | 5-15 days (prototype) 20-30 days (production) | Quick prototypes to full production runs |

Quantity | 1 to 10,000+ pieces | One-off custom parts to large orders |

We stand out because:

Our machinists have years of experience with steel

Our machines can make complex parts quickly

We check every part to ensure it meets specifications

We help with design advice and material selection

We offer great value without sacrificing quality

At Istar Machining, we follow a careful process:

We check your designs to make sure they'll work well

We create detailed instructions for our CNC machines

Our advanced machines cut and shape the steel

We measure every part to ensure it meets specifications

We clean, polish, or treat the surface as needed

Ready to make your steel parts with Istar Machining? Here’s how:

For custom steel parts that meet exact specifications, trust the experts at Istar Machining. Our custom CNC steel services deliver the quality and precision your project demands.

Contact us today to discuss your steel CNC machining needs!

Steel CNC machining uses computer-controlled tools to shape steel into exact parts. Our machines follow digital plans to cut, drill, and shape steel with perfect accuracy. At Istar Machining, we use top-quality machines to make parts that meet your exact needs.

Simple parts can be done in 5-7 days. Complex parts or large orders take 2-4 weeks.

We can make features as small as 0.5mm in most steels.

Yes, we use special tools and techniques for hardened steel, though it may take longer.

CNC milling uses rotating tools to cut material, while CNC turning spins the material against fixed tools.

We help pick the right steel based on strength needs, environment, budget, and how the part will be used.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or