Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Today, we’re going to explore two words that sound alike but have very different meanings: stress and strain. If you dream of being an engineer or just enjoy making things, knowing the difference between stress and strain is incredibly important. It’s the key to making sure our buildings, bridges, and even our toys are built strong and safe. In this guide, I’ll use my experience as an engineer to help you see what these words mean and why they are a very important idea in science and engineering.

Have you ever stretched a rubber band? That pulling feeling is a kind of force. Now, picture that force spreading out across the entire rubber band. That gives you an idea of stress! For an engineer, stress is the amount of force pushing or pulling on a specific area of a material. Think of it like a backpack. With only one strap, all the bag’s weight (the force) pulls on a tiny part of your shoulder. That’s a high amount of stress! But if your backpack has two wide, soft straps, that same weight is spread over a larger area. This means there is less stress on any one spot.

An engineer is always thinking about stress. When they design a bridge, they must figure out how much stress the cars will put on the bridge’s supports. They measure this as force per unit area. If a material has too much stress, it can cause a major problem, like a crack or a complete failure. This is why knowing about applied stress is a very important part of creating things that are built to last.

Let’s return to our rubber band. When you pull on it, what does it do? It gets longer! That change in shape is called deformation. Strain is simply our way to measure that deformation. It’s not just about how long it gets, but how much longer it gets compared to its original length. For instance, if a rubber band that is 10 inches long stretches to 11 inches, it changed by 1 inch. The strain is that 1-inch change divided by the starting length of 10 inches.

Strain shows an engineer how a material acts when under stress. When you apply a force to a material, you create stress inside of it. The material then responds to this stress by changing its shape, and we call that change strain. You can have a strain that makes a material longer (like stretching the rubber band) or one that makes it shorter when you squeeze it. This is known as compressive strain. Any material will experience strain when a load is put on it.

This is the most important question! The biggest difference is that stress is the cause, and strain is the effect. You simply can’t have strain if there is no stress. You can think about it like this:

A simple way I keep the difference clear is by thinking about studying for a big test. The pressure you feel to get a good grade is like stress. The long hours of studying that make you feel tired is the strain. The stress leads to the strain. In materials science and engineering, we can’t see stress with our eyes, but we can easily see and measure the strain, or deformation, that it causes.

Here is a simple table to show the difference:

| Idea | What it is | How to think about it |

|---|---|---|

| Stress | The pushing or pulling force inside a material over an area. | The “pressure” a material is under. |

| Strain | The change in a material’s shape because of stress. | The “stretch” or “squish” of a material. |

For any engineer, the relationship between stress and strain is one of the most vital things to understand. Every single material, from steel and plastic to wood, has a point where it can’t take any more stress before it either changes its shape for good or breaks. By knowing this relationship, an engineer can pick the perfect material for a project. For instance, the material used for an airplane’s wing has to handle a great deal of stress with very little strain, so the wing doesn’t bend out of shape.

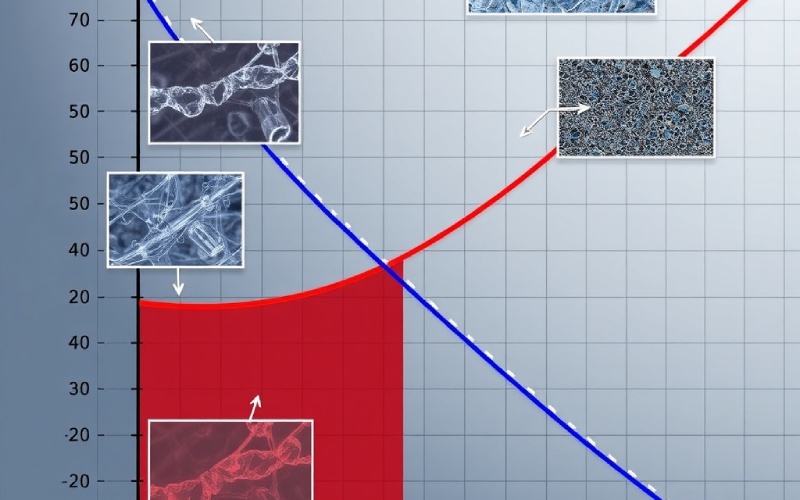

Engineers do testing on a material to see how it will behave when stress is applied. They will pull, push, and twist a small sample of the material to watch how it acts. This testing allows them to make a special chart called a stress-strain curve, which is like a secret map showing the material’s property. This testing is a very important part of the design and manufacturing steps. Without this knowledge, making things would be like taking a wild guess, and that is not a safe way to build!

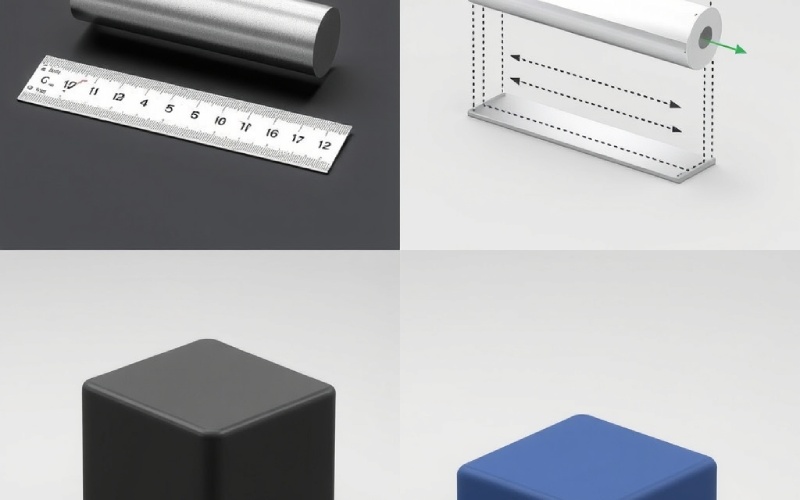

Let’s picture that we take a piece of a material, maybe a thin metal rod, and we put it into a special machine that pulls on it from both ends. The machine will slowly add more pulling force while it measures two things: the stress building up inside the metal and the strain (how much it is stretching). A stress-strain curve is a graphical drawing that shows this whole process. It is a graph that shows what is happening to the strain as we apply more and more stress.

This curve is extremely useful to an engineer. It tells the complete story of a material while it is being pulled apart. It shows the material’s strength, how much it can stretch before it might break, and if the deformation is something that will go away or will stay forever. The stress-strain curve is a graphical representation that lets us see the mechanical behavior of any material.

At first glance, a stress-strain curve can look a bit confusing, but it is actually quite simple to read once you learn its main parts. The stress is almost always shown on the up-and-down line (the y-axis), and the strain is shown on the line that goes from side-to-side (the x-axis).

When a material is put under too much stress, it can lead to failure. But failure does not always mean the material will shatter into many pieces. The first kind of failure happens when we go past the yield point. At this stage, the material has plastic deformation, which means it is now permanently bent or stretched out. For an engineer, this is usually seen as a failure because the part no longer has the correct size or shape to work the right way.

If you keep adding more stress beyond the ultimate strength, the material will start to “neck,” which means it gets very skinny in one location. Not long after that, it will fracture, or break, completely. An engineer always tries to make sure their design keeps the stress on all the parts well below the yield strength and especially the ultimate tensile strength. This makes sure that the things we use each day are safe and can be trusted.

No, not at all! Each material has its very own special stress-strain curve. This is why different materials are good for different jobs. We can put materials into two main groups based on what their curves look like: ductile and brittle.

An engineer has to pick the right kind of material for every job. For the bumper on a car, a ductile material is a good choice because it can get a dent and soak up the energy of a crash. For a kitchen knife, a very hard but more brittle material is better because it can hold a sharp edge.

Like I said before, an engineer cannot just guess a material’s properties by looking at it. They must perform careful testing. This is a huge part of materials science and engineering. The most popular test is called the tensile test. For this test, a specimen (which is a small, specially shaped sample) of the material is put into a special machine.

This machine then pulls on the specimen with a very carefully controlled applied force. It has special tools that measure how much force is being used and how much the specimen is stretching. Using this information, the engineer can figure out the stress (the force divided by the material’s cross-section area) and the strain (the change in its length divided by the starting length). All of these numbers are drawn on a graph to make that very important stress-strain curve. This curve provides the engineer with the very important information they need, like the material’s modulus of elasticity, its yield strength, and its tensile strength.

The ideas of stress and strain are everywhere you look. The chair you are sitting in right now was designed to handle the stress of your weight without too much strain. The buildings where we live and go to school are built with materials like steel and concrete that are able to handle huge amounts of compressive stress. How well these materials and structures work is all about how well their designers understood stress vs strain.

The next time you look at a tall building or a long bridge, think about the unseen forces that are at work. Every single piece of that structure is feeling stress, and because of that, a small amount of strain. It is the job of an engineer to understand this amazing behavior of materials so they can build a safe and wonderful world for everyone. The relationship between stress and strain is a basic idea that helps make the world we live in today possible.