Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for surface grinding that hits the mark every time? At Istar Machining, we turn rough parts into mirror-smooth surfaces with our top-notch surface grinding services. Let’s dive into what makes our grinding stand out and why it matters for your parts.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Surface grinding is when we use a spinning wheel to remove tiny bits of material from a part. This makes the part flat, smooth, and exactly the right size. Think of it like using super-precise sandpaper that can make metal as smooth as glass!

We use both manual grinders for special projects and CNC grinders for parts that need to be exactly the same every time. This helps us handle everything from quick one-offs to big production runs.

What We Can Do | Details | Why It Matters |

Machine Types | CNC Grinders (MÄGERLE, BLOHM) and Manual Grinders | CNC for perfect repeatability, manual for special care |

Materials We Grind | Steel, stainless steel, aluminum, titanium, ceramics, plastics, rubber | No matter what you make, we can grind it |

How Precise We Get | Down to ±0.0001″ (thinner than a human hair) | Your parts will fit together perfectly |

Size Capability | Up to 72″ x 120″ x 36″ (bigger than a car!) | From tiny medical parts to huge machine bases |

Surface Finish | Mirror-smooth at 4 μin Ra | Looks beautiful and works perfectly |

Check out our CNC grinding services for even more precision options!

Our surface grinding services are essential to many industries. Here’s who we help:

When planes and rockets need parts that must be perfect, our grinding delivers. From turbine parts to landing gear, we make sure everything meets sky-high standards.

Doctors trust tools that we've ground to perfection. Our grinding helps make surgical instruments, implants, and medical devices that are safe for patients.

Cars run smoother and last longer with our precision-ground parts. We help with engine components, molds for parts, and testing equipment.

Military equipment must work every time. Our grinding helps make reliable parts for weapons systems, vehicles, and communications gear.

Robots move smoothly because their parts fit together perfectly. Our grinding helps create the precise gears and components that make this possible.

No Conflict of Interest

We’re here to help you, not compete with you. We’re a pure subcontractor, so your business stays your business.

Speed & Precision

We’ve mastered the balance between working fast and being super accurate. Our special coolant systems help us make perfect finishes without slowing down.

We Keep Secrets Safe

Got a top-secret project? We understand. We offer NDAs (Non-Disclosure Agreements) to protect your ideas and designs.

When you choose our surface grinding services, here’s what happens:

Want to see how this compares to other services? Check out our cylindrical grinding services.

Surface grinding is ideal for achieving high precision, flatness, parallelism, and excellent surface finishes. Our capabilities allow us to work with a diverse range of hard materials. Here’s what we commonly process:

Metals

(Common Grades: A2, D2, O1, M2, S7, H13, CPM series) are known for their high hardness, wear resistance, and ability to hold a sharp edge. They are frequently ground after heat treatment to achieve final dimensions and required tolerances.

Good for:

Why customers choose it: “Surface grinding allows us to achieve the critical flatness, parallelism, and fine surface finish required on hardened tool steel components, ensuring optimal performance and tool life.”

(Common Grades: 303, 304, 316, 410, 420, 440C, 17-4 PH) offer excellent corrosion resistance combined with good strength. Different grades have varying levels of hardness and grindability. Often ground for precision applications in demanding environments.

Good for:

Why customers choose it: “Grinding provides exceptionally smooth, precise, and corrosion-resistant surfaces on stainless steel parts, vital for hygiene, performance, and longevity in challenging conditions.”

(Common Grades: 1018, 1045, 4140, 4340, 8620) are versatile ferrous materials offering a range of strengths and hardness levels (often enhanced by heat treatment). Surface grinding is used extensively for flatness and finish.

Good for:

Why customers choose it: “It’s a cost-effective method to achieve tight tolerances on flatness, parallelism, and specific surface finishes for a wide variety of common mechanical and structural parts.”

(Common Types: Gray Iron, Ductile Iron) offers excellent vibration damping, good machinability (though abrasive), and wear resistance. Typically ground to create flat, stable mating or sliding surfaces.

Good for:

Why customers choose it: “Grinding creates the extremely flat, stable, and wear-resistant surfaces necessary for machine tool accuracy, effective sealing, and reliable performance in cast iron components.”

(Common Grades: 6061, 7075, 2024, Cast grades, MIC-6) is lightweight, corrosion-resistant, with high thermal and electrical conductivity. Grinding aluminum requires specific techniques (specialized wheels, coolants) to prevent wheel loading but can achieve excellent finishes.

Good for:

Why customers choose it: “While challenging, grinding aluminum provides superior flatness and surface finish compared to other methods when these characteristics are critical for the application.”

(Common Grades: Grade 2, Grade 5 / Ti-6Al-4V) is known for its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. Grinding is challenging due to its reactivity and heat generation but necessary for precision applications.

Good for:

Why customers choose it: “For critical titanium parts in aerospace and medical fields, grinding is essential to meet stringent requirements for tolerance, surface integrity, and finish.”

(Examples: Inconel, Hastelloy, Monel, Waspaloy) are nickel-, cobalt-, or iron-based alloys designed for extreme environments (high temperature, high stress, corrosive). They are very difficult to machine and grind, requiring specialized expertise.

Good for:

Why customers choose it: “Grinding is often the only feasible method to achieve the necessary dimensional accuracy and surface integrity on complex superalloy parts destined for the most demanding applications.”

Ceramics

(Examples: Alumina / Aluminum Oxide, Zirconia, Silicon Carbide / SiC, Silicon Nitride / Si3N4) are extremely hard, wear-resistant, stable at high temperatures, and often electrically insulating. Due to their hardness and brittleness, grinding (typically with diamond abrasives) is a primary method for shaping and finishing.

Good for:

Why customers choose it: “Grinding is indispensable for precisely shaping and finishing ultra-hard ceramic components, enabling their use in applications where metals fail due to wear, temperature, or corrosion.”

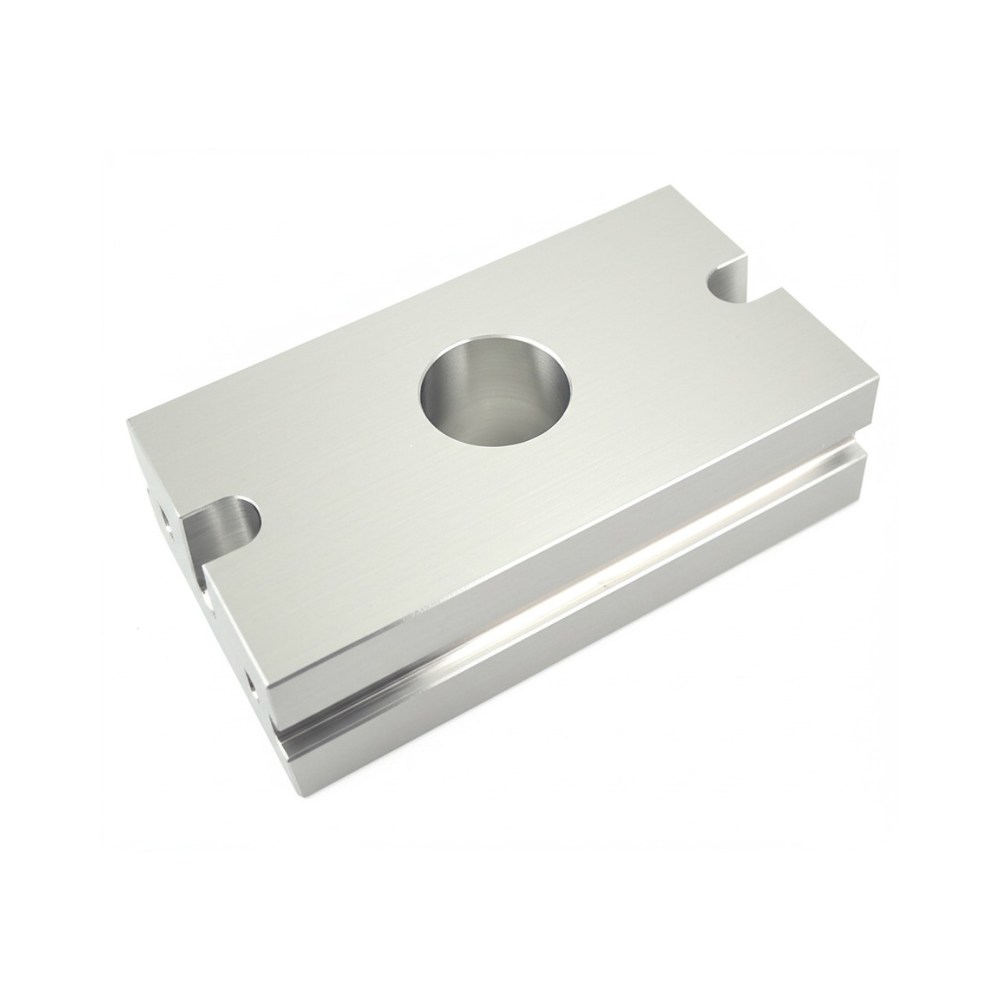

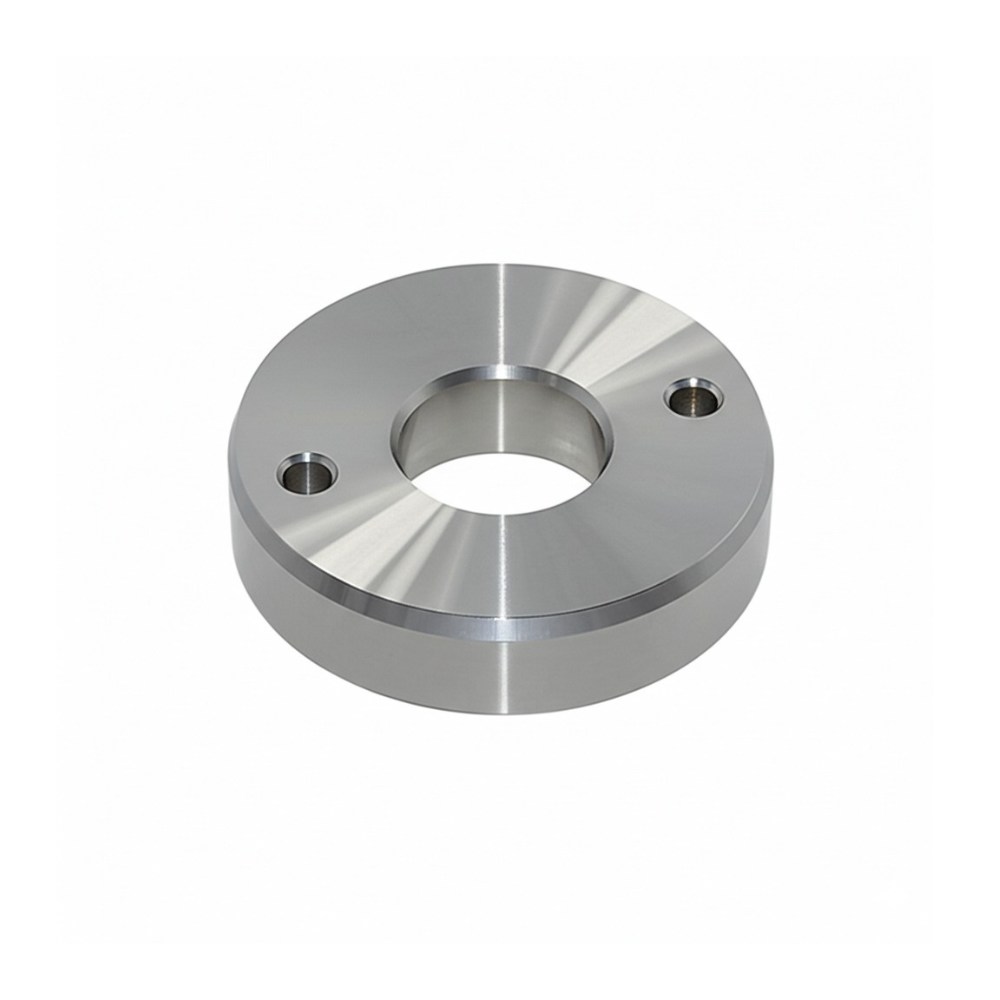

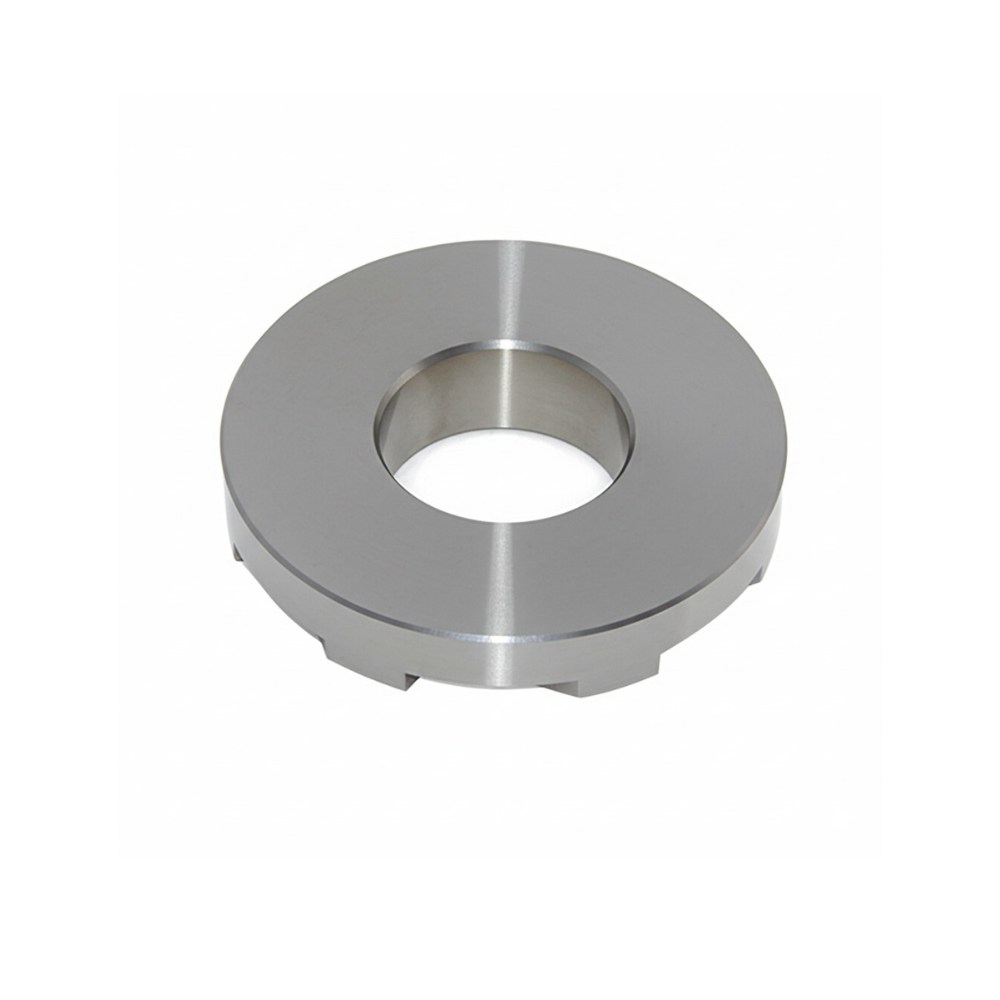

Here are some typical uses for our surface grinding services:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our grinding team has decades of combined experience.

Our machines represent the best in the industry.

We're ISO 9001 certified and follow strict quality checks.

Need it yesterday? We offer rush services for emergencies.

We can handle your project from start to finish.

Ready to make your parts perfectly smooth and precise? Let’s talk about your surface grinding needs!

Request a Quote Today!

Don’t settle for parts that are “close enough.” Get the precision your project deserves with our expert surface grinding services.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or