Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

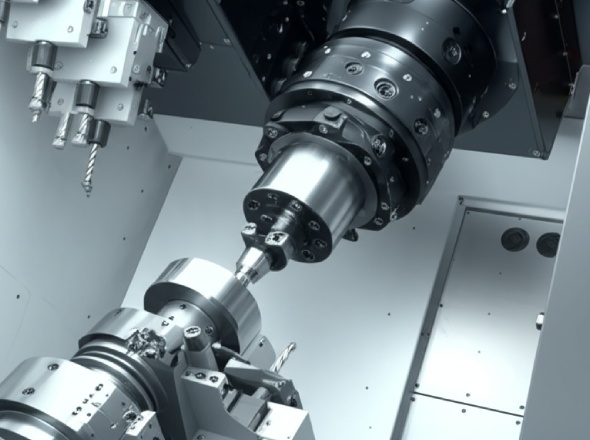

Are you looking for a way to make super small parts with amazing accuracy? At Istar Machining, we’re experts in Swiss machining, a special type of manufacturing that makes the tiniest parts with the tightest tolerances. From medical devices to aerospace components, our Swiss machining service delivers precision that you can count on.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

Swiss machining (also called Swiss turning or Swiss-type lathing) is a special way to make small metal parts. Unlike regular machine tools, Swiss machines hold the material in a special guide bushing while it moves through the machine. This helps make very small, precise parts without them bending or vibrating.

This technique was first created in Switzerland to make tiny watch screws. Today, we at Istar Machining use it to create parts for many industries where small size and high precision matter.

“Swiss machining is like having a microscope for metalworking – it lets us create parts so precise they can fit inside the eye of a needle!” – Engineering Team at Istar Machining

Swiss machines are different from regular CNC machines. Here’s what makes them special:

This design makes Swiss machining perfect for small, complex parts that need to be extremely accurate. At Istar Machining, we use the latest Swiss machines with up to 13 axes of movement!

Our Swiss machining service can handle many different materials:

Metals

Known for their corrosion resistance, strength, and hygienic properties, making them ideal for medical, food processing, and demanding industrial applications.

Common Grades:

Our Expertise: Achieving fine finishes and holding tight tolerances on diverse stainless steel grades.

Valued for their lightweight nature, excellent strength-to-weight ratio, good machinability, and thermal conductivity. Widely used in aerospace, electronics, and consumer products.

Common Grades:

Our Expertise: Proficient in high-speed machining of complex aluminum components.

Offering a balance of strength, durability, wear resistance, and cost-effectiveness for various mechanical and structural applications.

Common Grades:

Our Expertise: Delivering robust and reliable steel components via precision Swiss turning.

Selected for their excellent machinability (especially brass), high electrical and thermal conductivity (copper), corrosion resistance, and aesthetic appeal.

Brass:

Copper:

Bronze:

Beryllium Copper (BeCu):

Our Expertise: Specialists in high-volume production of intricate brass fittings, connectors, and high-conductivity copper contacts.

Renowned for their exceptional strength-to-weight ratio, excellent biocompatibility, and superior corrosion resistance, particularly in harsh environments. Ideal for medical implants, aerospace components, and high-performance applications. Machining requires specific expertise.

Common Grades:

Our Expertise: Proven experience in the demanding, precise machining of titanium alloys.

Designed for extreme conditions involving high temperatures, high stress, and corrosive environments. These materials are often challenging to machine and require specialized knowledge.

Examples:

Our Expertise: Mastery in handling difficult-to-machine exotic alloys for critical applications.

Plastics

A high-performance thermoplastic renowned for its exceptional mechanical strength, stiffness, and creep resistance, maintained even at continuous operating temperatures up to ~250°C (480°F). PEEK offers outstanding chemical and hydrolysis resistance, inherent flame retardancy, excellent wear properties, and good dimensional stability. Often specified in medical grades (USP Class VI compliant) for implants, surgical instruments, and analytical equipment components due to its biocompatibility and sterilizability. Also widely used in demanding aerospace, semiconductor, and industrial applications requiring high performance. Machines well to tight tolerances with appropriate tooling.

Available as homopolymer (e.g., Delrin®) and copolymer grades, Acetal is known for its high stiffness, excellent dimensional stability, low coefficient of friction (natural lubricity), and good wear resistance. It exhibits low moisture absorption, making it ideal for precision parts operating in wet or humid environments. Commonly machined into small gears, bearings, bushings, rollers, electrical insulators, and complex mechanical components requiring consistent, tight tolerances. Offers outstanding machinability, yielding clean finishes and precise details.

A versatile family (including common grades PA 6 and PA 6/6) known for its good toughness, high impact strength, excellent abrasion resistance, and resistance to many chemicals, oils, and fuels. Available in various grades, including glass-filled or MoS2-filled options for increased strength, stiffness, and wear properties. Frequently used for bearings, rollers, gears, structural parts, wear pads, and insulators. Note: Nylon is hygroscopic (absorbs moisture), which can affect dimensional stability and mechanical properties; this must be considered during design and machining for critical tolerance applications.

Distinguished by its extremely broad operating temperature range (approx. -200°C to +260°C / -328°F to +500°F), near-universal chemical inertness, and an exceptionally low coefficient of friction (one of the lowest of any solid material). It’s also an excellent electrical insulator. While inherently soft and potentially prone to creep under load, precision machining is readily achievable with Swiss techniques. Ideal for high-purity seals, gaskets, valve seats, linings, insulators, non-stick surfaces, and low-friction bearings (especially when filled with glass, carbon, or bronze to improve mechanical properties).

An amorphous, high-performance thermoplastic offering high strength, rigidity, and dimensional stability, particularly at elevated temperatures. Features excellent electrical properties (high dielectric strength and stable dielectric constant), broad chemical resistance, and inherent flame resistance (UL94 V-0). Resistant to hydrolysis, making it suitable for repeated steam sterilization cycles. Common applications include medical instrument components, electrical connectors and insulators, semiconductor handling parts, and aerospace components. Typically amber/transparent in its natural state.

A tough, transparent thermoplastic known for its outstanding impact strength (high resistance to shattering) and good rigidity over a wide temperature range. Offers good electrical insulation properties and dimensional stability. While naturally transparent like glass, it has much higher impact resistance. Used for machine guards, sight glasses, durable housings, electrical components, manifolds, and various medical device components. Requires sharp tooling and appropriate speeds/feeds during machining to achieve clean cuts and avoid stress cracking.

A widely used and cost-effective thermoplastic available in rigid (uPVC) and flexible forms. Rigid PVC offers good chemical resistance (especially to acids, alkalis, and salts), durability, and inherent flame retardancy. It is also a good electrical insulator. Commonly machined into pipe fittings, valve components, chemical processing parts, electrical boxes, and housings where high strength or temperature resistance is not the primary requirement.

A common thermoplastic terpolymer valued for its good all-around balance of properties: toughness, high impact resistance (even at lower temperatures), rigidity, chemical resistance, and relative ease of processing and machining. Offers good dimensional stability and can be easily colored, painted, or plated for aesthetic finishes. Widely used for durable enclosures, housings, control panels, prototypes, and various consumer product components requiring good mechanical properties at a reasonable cost.

For engineers and technical buyers, here are the specifics of our Swiss machining capabilities:

Machine Specifications

Our Equipment

At Istar Machining, we use top-of-the-line Swiss machines:

Our Swiss machining services help many industries create their most important small parts:

Why choose Swiss machining for your small parts? Here are the biggest benefits:

At Istar Machining, we combine these advantages with our expertise in precision CNC machining to deliver parts that exceed your expectations.

There are many reasons to partner with us for your Swiss machining needs:

Our team has decades of combined experience

ISO 9001, AS9100, and ITAR compliance

Latest Swiss machines with full automation

From design assistance to finishing services

Efficient processes mean better value

We respect your deadlines and production schedules

When you work with Istar Machining for your Swiss machining needs, here’s what happens:

Our engineers review your CAD files to ensure they're optimized for Swiss machining

We help you choose the best material for your application

Our CAD/CAM specialists program the machine for your specific part

We make a sample part for your approval

Once approved, we begin full production

A: We can make parts with features as small as 0.3mm and tolerances of ±0.0005mm.

A: Stainless steel, brass, aluminum, titanium, and some plastics like PEEK work extremely well.

A: Swiss machining offers better precision for small parts, can achieve tighter tolerances, and is more efficient for high-volume production of small components.

A: While we specialize in higher volumes, we can accommodate orders as small as 100 pieces.

A: Typically 5-10 days for prototypes and 2-3 weeks for production runs, depending on complexity and quantity.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or