Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

I’ve been working with steel for a long time. I’ve seen them all, from usual steel to uncommon alloys. 2 products that frequently come up in conversation are titanium and tungsten carbide. People need to know the distinction. They ask, “Which one is much better?” The response, as I constantly tell them, depends on what you require it for. Both are outstanding materials, yet they have distinct properties. In this post, I’ll give you a comprehensive contrast of titanium vs. tungsten carbide. We will consider whatever from strength and density to their usage in jewelry and industrial applications. By the end, you’ll have a clear understanding of these 2 popular steels and have the ability to select the right one for your requirements.

When we speak about strength, it’s crucial to know that there are various sorts of strength. There’s tensile strength, which is just how much tension a product can take prior to it breaks. Then there’s hardness, which is exactly how well it can resist being scraped or dented.

Titanium has a really high tensile strength. It’s stronger than numerous sorts of steel, which goes for such a lightweight metal. This is why it’s utilized in the aerospace market, where you require a material that is both strong and light. However, titanium is not as difficult as tungsten carbide. On the Mohs scale of hardness, titanium obtains a 6, while tungsten carbide is a 9.

Tungsten carbide, on the other hand, is just one of the hardest materials on Earth. It’s incredibly scratch-resistant, which is a huge advantage for things that see a lot of wear, like reducing tools and jewelry. However, this hardness also makes tungsten carbide more brittle. If you hit it hard enough, it can fracture or smash. Titanium, being less brittle, is more likely to flex or flaw under influence.

The difference in density between these 2 products is big. Tungsten carbide is a really thick and hefty metal. Its density is around 15.6 g/cm THREE. To offer you an idea, that’s twice as hefty as steel and practically as heavy as gold. This weight can be an advantage in some applications where you need a lot of mass in a tiny space.

Titanium is the opposite. It’s known for being unbelievably lightweight. Its density is only about 4.5 g/cm³, which is about 45% lighter than steel. This is a significant reason why it’s so prominent in the aerospace market and for medical implants. When you’re developing an aircraft, every ounce counts. The high strength-to-weight proportion of titanium makes it a suitable product for this application.

| Product | Density |

|---|---|

| Titanium | 4.5 g/cm ³ |

| Tungsten Carbide | 15.6 g/cm FOUR |

This table plainly shows the large distinction in density and is a crucial factor to take into consideration when choosing between these 2 steels.

Durability is an additional word among those that can suggest various points. When we take a look at the durability of a metal, we need to think about things like resistance to scrapes, deterioration, and warm.

As I mentioned before, tungsten carbide is unbelievably hard and scratch-resistant. This makes it super sturdy in situations where it could be scratched or massaged against various other hard surfaces. A ring made from tungsten carbide will certainly look new for a long time. Nevertheless, its brittleness can be a drawback. A difficult effect might trigger it to fracture.

Titanium is not as scratch-resistant as tungsten carbide; however, it’s still a really sturdy metal. It’s highly corrosion-resistant, specifically in saltwater settings. This is why it’s typically utilized for marine applications and medical implants. Titanium likewise has good heat resistance, although tungsten carbide has a much greater melting point. The durability of a titanium alloy comes from its capacity to withstand stress and anxiety, and environmental variables.

Over the years, I’ve seen a large rise in the appeal of both titanium and tungsten carbide for rings, particularly wedding bands. Both are excellent alternatives to rare-earth elements like gold and platinum.

Here’s a fast contrast to help you pick:

The chemical building blocks of a material determine exactly how it reacts with its environment. This is essential for things like corrosion resistance and biocompatibility.

Titanium is popular for its exceptional corrosion resistance. It forms a thin, protective oxide layer on its surface that prevents it from rusting or corroding, even in extreme chemical environments. This is just one of the factors it so valuable in the medical field for things like implants. Most titanium is likewise hypoallergenic, meaning it’s not likely to cause an allergic reaction.

Tungsten carbide likewise has good corrosion resistance, yet it’s not as resistant as titanium. It can oxidize at very high temperatures. Some tungsten carbide alloys consist of cobalt, which can cause skin inflammation for some people. Nonetheless, many tungsten carbide rings are made with a nickel binder, which is hypoallergenic.

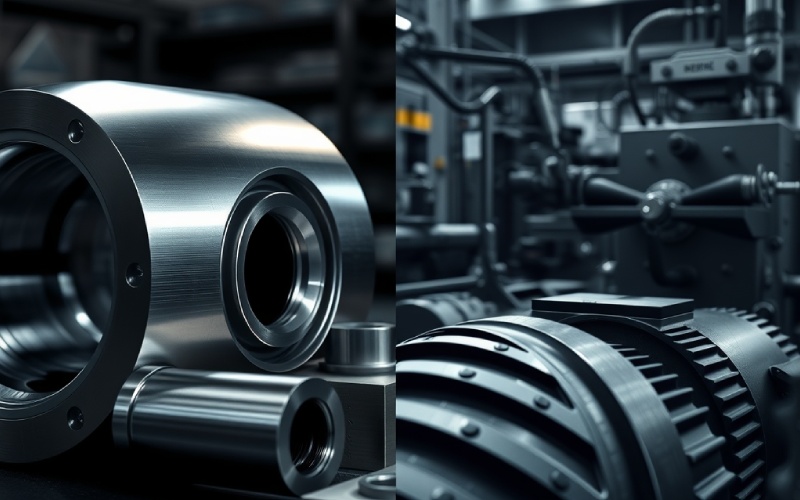

In the industrial world, both of these products are workhorses. Their distinct residential properties make them optimal for a vast array of applications.

Tungsten carbide is the king of cutting tools. Its extreme hardness and wear resistance make it best for drill bits, saw blades, and other machining devices. It can cut through other difficult materials with ease and lasts a very long time. It’s likewise used in mining tools and other durable machinery where there is a great deal of friction and wear.

Titanium is additionally utilized in manufacturing and heavy equipment, but also for various other factors. Its high strength and light weight make it an excellent choice for parts that require to be strong yet not heavy. The aerospace market is a huge user of titanium for whatever from plane frames to engine parts. Its corrosion resistance additionally makes it useful in chemical handling plants.

When it involves aerospace, every gram matters. The lighter an aircraft is, the less gas it uses. This is where titanium really radiates. Its unbelievable strength-to-weight ratio makes it the best product for building planes and spacecraft. It’s utilized for structural components, landing equipment, and other elements where strength and reduced weight are critical.

Tungsten carbide likewise has a location in the aerospace industry; however, its usage is more specialized. Since it’s so heavy, you would not intend to construct a whole airplane from it. Nonetheless, its hardness and warm resistance make it beneficial for certain high-performance parts like nozzles and bearings that need to withstand a lot of tension and high temperatures.

The process of turning raw ore into a completed product is different for both titanium and tungsten carbide.

Titanium is located in nature as an oxide and requires to be fine-tuned. The manufacturing process is complicated and energy-intensive, which contributes to its higher cost compared to steel. When the pure titanium metal is created, it can be developed right into various forms and usually mixed with other metals to create an alloy with specific properties.

Tungsten carbide is not a pure metal, but a compound of tungsten and carbon. The manufacturing procedure involves blending great powders of tungsten and carbon and afterwards heating them to a very high temperature in a procedure called sintering. This produces an incredibly difficult and thick material. Typically, a binder metal like cobalt or nickel is added to the alloy to raise its durability.

By now, you ought to have a great concept of the essential differences between these two materials. The choice actually comes down to what you need the product to do.

Below’s a straightforward overview to aid you in making a decision:

Consider the particular application. For a ring, do you favor a lightweight feeling or a hefty one? For an industrial device, is scratch resistance or impact resistance more vital? Answering these inquiries will lead you to the best product for the work.

I’ve remained in this market long enough to see a great deal of innovation, and I can inform you that the future is bright for both tungsten and titanium. Scientists are frequently dealing with developing new alloys for even better buildings.

We’re seeing brand-new manufacturing methods that might make these materials much more economical and much easier to collaborate with. This might open up a lot more applications for them in a range of areas, from medication to design. As modern technology continues to progress, the demand for high-performance materials like titanium and tungsten carbide will only grow. It’s an interesting time to be dealing with these phenomenal steels.