Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

What does each lathe cutting tool do? How do you choose the best one for your work? In this guide, I will show you the common tools you will use on a lathe machine. You will learn what each tool is for. You will also see why choosing the right tool is so important for your project. This will help you do a better job and stay safe while you work with your lathe.

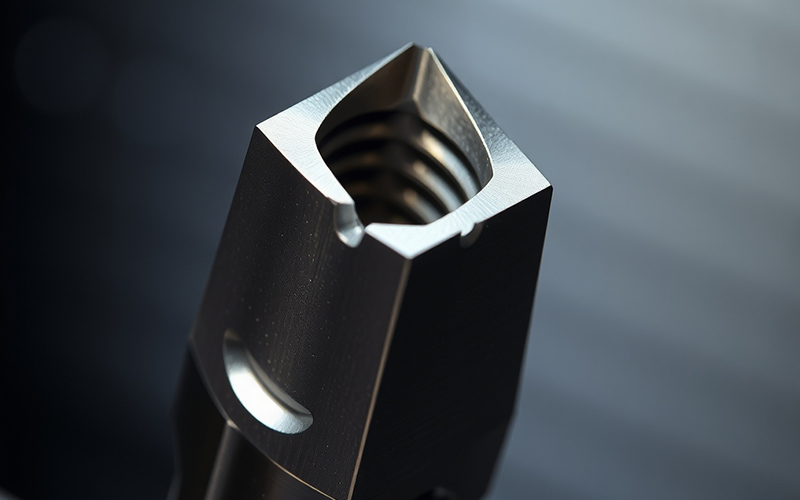

When I think about all the tools for a lathe, I group them in two main ways. The first group is solid tools. These are usually made of high-speed steel (HSS). This kind of steel has other metals in it, like tungsten, chromium, and vanadium. These metals make it very hard and able to handle a lot of heat. A solid lathe cutting tool is just one piece of metal. You have to sharpen it on a grinder. This gives it the right angle and makes it sharp.

The second group is tools that use small, removable tips. You see them a lot today in cnc machining. The tool has a body. This body holds a small part you can take out. This part is called an insert. The insert is the piece that does the cutting. These inserts are usually made from very hard things, like carbide. When one of the cutting edges gets dull, you can just turn the insert to a fresh edge. Or, you can put in a new one. This is much quicker than sharpening a solid tool. These carbide tools often have a special layer on top called a coating. This coating can be made of things like titanium. It helps the tools last a lot longer.

The feed direction is very important when you select a lathe cutting tool. This is the way the tool moves on the workpiece. This is the reason we have right-hand and left-hand tools. It is easy to understand when you see it. A right-hand turning tool cuts when it moves from the right side to the left side of the lathe. If you look down at the tool, its main cutting edge is on the left. The tool cuts as you move from right to left.

A left-hand tool works the other way. It is made to cut when it moves from the left side to the right side. Its cutting edge is on the left, so it works as you move from left to right. The left side of the tool does the work here. You have to pick the correct tool for the way you plan to cut. If you use a right-hand tool but try to move from left to right, it will not cut the right way. You could break the workpiece or the tool. The feed direction on your lathe is very, very important.

Over time, I have learned that a small group of common lathe cutting tools can do most jobs. Any shop that is producing turned parts will have these tools. If you are getting your own lathe, these are the first ones you should get. They do most of the heavy lifting in any turning job.

Here are some of the most common tools you will use:

If you have a good set of these, your lathe can be used for many different jobs. The tools used on a lathe decide what you can create.

I can tell you that the angle of your lathe cutting tool is a very big deal. It is not just a random shape. Each angle has a purpose. These angles help the tool cut cleanly and make it last longer. The right angle helps the cutting go smoothly and gives you a nicer finish. A single-point cutting tool has a few key angles that all work together.

The rake and back rake angles are very important. The side rake and back rake help control the little chip of metal. They make it curl and move away from the machined surface. A good inclination angle on the tool face also helps manage the force of the cut. This makes the cut on the lathe machine more steady. The clearance angle helps by stopping the tool from rubbing on the new surface of the workpiece. Every angle must be just right for the lathe tool to do its job well. The inclination angle is a very important part of this.

| Angle Name | Its Job | Why It Matters |

|---|---|---|

| Rake Angle | Manages how chips flow | Stops chips from getting stuck, makes cutting easier. |

| Clearance Angle | Stops the tool from rubbing | Lowers heat and rubbing, gives a better surface. |

| Lead Angle | Points the cutting force | Makes the cut more stable, helps stop shaking on the lathe. |

| Inclination Angle | Guides the metal chip | Pushes the chip away from the part and the tool. |

A turning tool is the most basic lathe cutting tool you will use. Its main job is to remove material from a workpiece along its side. This makes the round workpiece have a smaller diameter. Think about having a thick, cylindrical bar. If you want to make it thinner, you will use a turning tool. The tool moves straight along the spinning workpiece, parallel to its axis.

There are two main kinds of turning tools. First are the rough turning tools. These tools are strong. The tools are designed to remove large amounts of material in a short time. They are not meant to make a pretty surface. They are all about being fast. After you use a roughing tool, you use finish turning tools. These tools take off a very thin layer of metal. They have a special angle and shape that makes the surface smooth and exact. A good turning tool is something you must have for any lathe project. This lathe cutting tool is a must-have. A good turning tool gives you a good finish.

Sometimes, you need the end of your cylindrical workpiece to be perfectly flat. This is the job for a facing tool. A facing tool is a single-point tool. It is mounted on a lathe in the tool post. To use it, you move the tool from the center of the workpiece out to the edge. You can also move it from the edge to the center. This outward or inward movement is radial. It shaves off a tiny bit of metal. This leaves a flat and smooth end.

This job is called facing. It is often the very first thing you do to a new piece of metal in the lathe. It helps clean up the rough end from the saw. It also gives you a true, flat surface to take your measurements from. A good facing tool has strong cutting edges. It also has the right clearance angle so it can cut without rubbing. Using a facing tool is a basic skill for anyone who uses a lathe machine. The facing tool helps make sure your part starts out right.

Making holes is a job you will do a lot on a lathe. The main tool you use for this is a drill. You can put a drill bit in the tailstock of the lathe. The workpiece spins in the chuck. Then, you push the drill into the center of the part to make a hole. This is good for making a starting hole. It is also good for a hole that does not need to be perfectly exact. A drill is a simple but useful type of lathe cutting tool.

If you need to make a hole bigger or more exact, you will need a boring bar. A boring bar is a long, stiff metal bar. It has a tiny single-point cutting tool on its tip. The boring bar can reach deep inside a hole that is already in the workpiece. As the lathe spins the part, you feed the boring bar into the hole to make it wider. This is called boring. It helps you make holes that are very accurate and have tight tolerances. A boring bar is a special lathe cutting tool for working on the inside of a part. The boring bar is needed for high-quality work. You need a boring bar for a perfect inside diameter.

Cutting a thread on a lathe is one of its best tricks. You can make your own bolts or nuts. To do this, you need special thread cutting tools. These tools have a tip that has been shaped very carefully. It is usually a 60-degree “V” shape. This shape matches the thread you want to make. Getting this specific shape right is very important for a good thread.

You set up the lathe to move the tool a very exact distance each time the workpiece turns around once. This is what makes the spiral shape of the thread. You make the thread by taking many small cuts. You feed the tool in a little bit deeper on each pass. You keep going until the thread is the right depth. There are tools for making external threads (on the outside, like a bolt). There are also tools for making internal threads (on the inside, like a nut). Using these tools used to create a good thread is a skill that you learn with practice. Making a nice, clean thread on the lathe is a great feeling.

The lathe can do more than just the basic stuff. It can do many other special types of cutting. For example, you may need to cut a thin channel, or groove, in a part. To do this, you use a grooving tool. A grooving tool looks like a thin blade. You push it straight into the part while it spins. It can be used to create a space at the end of a thread. It can also make a channel for a rubber O-ring. A parting tool is a kind of grooving tool. You use it to cut all the way through the workpiece to slice off a finished part. The parting tool has to be very strong and sharp. A grooving tool is also very useful.

Another special job is knurling. Knurling doesn’t really cut the metal. It presses and shapes it. A knurling tool has two hard wheels with a pattern on them. You press these wheels hard against the workpiece. As the lathe spins the part, the wheels press a diamond or straight-line pattern onto the surface. This is often used to make a grip on handles and knobs. It makes them easier to hold and look better, too. These special tools, like the forming tool and knurling tool, let you do much more on a lathe. A forming tool can also be used to create a specific shape by pushing it straight into the workpiece.

Choosing the right tool for the metal you are cutting is one of the biggest lessons I have learned. You have to select the right tool based on the hardness of the workpiece metal. A tool that cuts aluminum easily might break right away on hard steel. The most important things to think about are the tool’s material, its shape or angle, and any special coating it may have.

For softer metals like aluminum or brass, high-speed steel (HSS) tools work great. They are not too expensive and you can sharpen them yourself. For harder metals like steel and cast iron, you will need to use carbide tools. Carbide stays hard even when it gets very hot. For very, very hard materials, you may need tools made of cubic boron nitride (CBN). CBN is one of the hardest things you can get. It is suitable for machining very strong metals. The hardness of the metal tells you what tool to choose. This is the secret to good cnc machining. You must choose a lathe cutting tool that is compatible with your workpiece. I always check the hardness of my material before I select a lathe tool.

Here is a quick list of the most important things I’ve learned about using a lathe: