Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

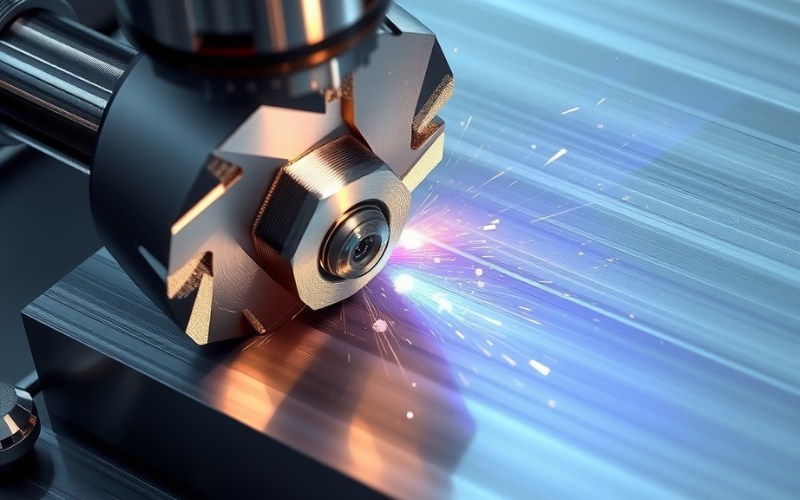

Milling operations are a versatile and powerful process that shapes our globe, from the vehicle you drive to the phone in your pocket. In this short article, I’m mosting likely to stroll you via the different sorts of milling operations. I’ll discuss what they are, how they function, and when to utilize them. Whether you are brand-new to the world of CNC machining or a seasoned pro, I believe you’ll find something valuable here. So, let’s dive in and explore the interesting world of the milling process.

At its core, a milling operation is a manufacturing process that makes use of a rotating cutting tool to get rid of material from a workpiece. Think of it like a very exact and effective carver’s sculpt. The device, often a CNC (Computer System Numerical Control) device, relocates the cutting tool or the workpiece along multiple axes to produce complex forms and layouts. The heart of the milling operation is the milling cutter, which can have numerous cutting sides. This machining procedure is exceptionally flexible and can be used on a vast array of materials, consisting of steels, plastics, and composites.

The type of milling machine utilized, such as horizontal and upright milling devices, likewise contributes in the sort of procedures that can be executed. These machines can be configured with computer-aided manufacturing (CAMERA) software to perform complex and exact cuts, making the milling process important in industries such as aerospace and automobile. The capability to remove product with such precision makes grating a fundamental component of contemporary manufacturing.

There are many different kinds of milling operations, each developed for a details purpose. Consider it like a tool kit; you have various devices for various tasks. A few of one of the most common sorts of milling operations include face milling, end milling, side milling, and slot milling. There are also extra specialized operations like gear milling and thread milling.

Here is a glance at some of the different milling strategies:

| Kind of Milling | Main Use |

|---|---|

| Face Milling | Developing big, flat surfaces. |

| End Milling | Developing ports, pockets, and shapes. |

| Side Milling | Machining the sides of a workpiece. |

| Slot Milling | Reducing a groove or slot right into a workpiece. |

| Angle Milling | Developing angled surface areas, chamfers, and bevels. |

| Form Milling | Making facility and uneven contours. |

| Gear Milling | Creating the teeth on a gear. |

| Thread Milling | Cutting strings on a workpiece. |

Each of these sorts of milling operations utilizes a particular sort of milling cutter and machine setup to achieve the wanted outcome. The choice of which milling operation to utilize depends upon the form, dimension, and features of the final component.

Selecting the right sort of milling operation is critical for getting the specific preferred results. The initial point I take into consideration is the geometry of the component. If I need a big, level surface, face milling is the way to go. For elaborate details like a pocket or an intricate shape, I would certainly turn to an end mill. The product of the workpiece is another vital aspect. Hard products might need a different type of milling cutter or a slower cutting rate to avoid damage to the device.

The capabilities of your CNC machine are additionally a crucial consideration. A machine with more axes of activity allows for more complicated layouts and can execute various kinds of milling operations in a solitary arrangement. As an example, a 5-axis machine can develop extremely intricate shapes that would certainly be impossible on a 3-axis machine. Eventually, the objective is to select the milling process that will certainly generate the component effectively and with the called for accuracy.

Face milling and end milling are two of one of the most common kinds of milling operations, and it is very important to recognize the distinction. I commonly make use of face milling to produce a flat, smooth surface area on a large area of a workpiece. In this procedure, the axis of the face mill is perpendicular to the surface being machined. The face mill itself has reducing edges on both its face and its periphery, enabling it to get rid of material rapidly and effectively. This type of milling is suitable for the very first step in a machining procedure, preparing the workpiece for additional procedures.

End milling, on the various other hand, is much more flexible. An end mill has cutting sides on its end and its sides, which allows it to reduce in several instructions. I utilize an end mill to create a variety of functions, consisting of a slot, a pocket, a shape, and various other intricate forms. The end mill can plunge directly right into the workpiece like a drill bit and after that move laterally to remove material. This makes completion milling operation excellent for producing intricate details. You can also utilize an end mill for some face milling tasks, yet a dedicated face mill is typically more effective for big, level surfaces.

When I require to develop a slot or a groove in a workpiece, slot milling is the best operation. This type of milling operation utilizes a specialized milling cutter, typically called a slot cutter or a round saw blade, to reduce a slim channel. The slot can be of any kind of size and can be straight or rounded. An usual application for slot milling is creating keyways, which are slots used to safeguard a gear or wheel to a shaft.

You can additionally use an end mill for slotting procedures. In this situation, completion mill plunges right into the product and then moves along the desired path to develop the slot. The size of the slot is established by the size of completion mill. For broader ports, several passes with completion mill might be needed. The accuracy of a CNC machine makes it feasible to develop a slot with really tight resistances, which is typically crucial in manufacturing.

Side milling is a kind of milling operation where the cutting tool eliminates product from the side of a workpiece. I utilize this method to produce flat, upright surface areas, shoulders, and even a groove. The milling cutter utilized for side milling can be a side milling cutter or an end mill. The machine can be either a straight or vertical milling machine.

During the side milling operation, the periphery of the turning cutter engages with the side of the workpiece to get rid of product. The depth of the cut can be precisely regulated, enabling the production of features with precise measurements. This procedure is common in many manufacturing applications, from creating the level sides of a block to machining detailed accounts on a component.

Yes, definitely! Angle milling is a type of milling operation that I make use of to create surfaces that are at an angle to the major axes of the workpiece. This is frequently necessary for creating attributes like chamfers, bevels, and syncs. To execute angle milling, you can either turn the workpiece or use a special milling cutter with a tilted cutting edge.

Single-angle milling cutters have teeth on one angled face, while double-angle milling cutters have V-shaped teeth. These cutters allow for the accurate machining of tilted surfaces. Modern CNC machines with several axes of movement make angle milling a lot easier and a lot more accurate. The ability to develop tilted functions is essential in several industries, consisting of aerospace, where intricate geometries prevail.

Form milling is a truly fascinating type of milling operation that enables me to develop complex, uneven shapes on a workpiece. As opposed to utilizing a basic level or tilted milling cutter, form milling utilizes a custom-shaped cutting tool that matches the desired profile of the final part. This form milling cutter can be convex, concave, or have any kind of various other facility form.

I discover form milling to be extremely effective for producing parts with intricate styles, such as gear teeth, attractive moldings, and coining passes away. The procedure can usually create the whole account in a solitary pass, which saves time and makes sure consistency throughout several parts. While the custom milling cutter can be a lot more costly to generate, the performance gains in high-volume production usually make it an economical choice. This type of milling is widely made use of in the aerospace, automotive, and medical sectors.

Yes, a CNC machine is perfectly with the ability of creating a gear. This is done via a specialized type of milling operation called gear milling. Gear milling is an accuracy machining process made use of to create the teeth on a gear. The process can use either a form milling cutter formed like the room in between the gear teeth or a process called hobbing.

Gear hobbing is an extra constant process where both the gear blank and the hob (the cutting tool) rotate in an integrated way to create the gear teeth. CNC modern technology has made gear milling far more accurate and efficient. The ability to generate high-precision gears is crucial in many industries, consisting of automobile and aerospace, where the smooth and reputable transmission of power is important. This is an excellent example of how a particular type of milling can address a very certain manufacturing challenge.

When I require to produce threads on a workpiece, I typically transform to thread milling. This is a sort of milling operation that uses a specialized cutting tool called a thread mill to reduce interior or external strings. The string mill turns and moves in a helical course to create the threads. This process is extremely functional and permits the development of a wide variety of string dimensions and pitches.

One of the huge advantages of thread milling is that a single tool can be used to produce strings of various sizes, as long as the pitch coincides. Thread milling is also an excellent selection for developing threads in tough products or for large size holes where tapping might be difficult. The accuracy of a CNC machine guarantees that the strings are produced with a high degree of precision. This operation is crucial for producing elements that need to be screwed together, which is common in virtually every market.

When we talk about the various kinds of milling operations, it’s additionally essential to recognize the two main cutting methods: climb milling and conventional milling. The difference in between them lies in the connection between the turning of the milling cutter and the instructions of the workpiece feed.

In conventional milling (or up milling), the cutter revolves versus the direction of the feed. This suggests the chip begins slim and gets thicker as the cutter moves along. This technique was commonly chosen due to the fact that it aided to get rid of backlash in older, hand-operated milling machines.

In climb milling (or down milling), the cutter revolves with the direction of the feed. The chip starts thick and gets thinner. A lot of modern CNC machines are created to take care of climb milling, and it is usually the recommended approach because it can create a far better surface area finish and prolong the life of the cutting tool. The option in between climb and conventional milling depends on the device, the material, and the desired finish.