Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

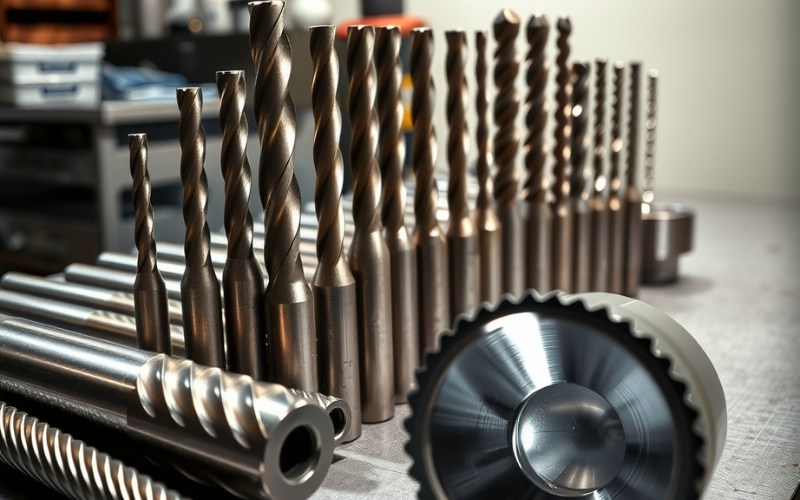

I’ve been in my workshop for a long time. I can tell you that making a perfect hole is not as easy as just using a drill. If you need a hole to be a very exact size and have a smooth inside, you need a special tool. That tool is a reamer. In this article, I will share what I know about the many types of reamer tools used in machining. We will look at all kinds of them, from a simple hand reamer to a strong carbide machine reamer. Reading this will help you get the precision you need for your work. You will learn how to pick the right reamer tools for any job.

A reamer is a really neat cutting tool. I see it as a tool for finishing touches. You do not use it to make a hole from nothing. Instead, a reamer is used to enlarge an existing hole by just a little bit. The main reason for this machining process is to make the hole’s diameter very, very exact. It also makes the inside of the hole have a very smooth surface finish. When you drill a hole, it might not be perfectly round. It also might not be the exact size you want. A reamer can fix that. This rotary cutting tool is made to take off a small amount of material. This makes sure the final hole size is just right and has the correct tolerance.

I have learned that using a reamer is a very important part of many machining operations. This is especially true in places like the aerospace industry. There, precision and accuracy are the most important things. Think about parts that must fit together perfectly. A reamer helps you get that perfect fit. The work starts after a hole is drilled. The reamer, which is a rotary cutting tool, then goes into the pre-drilled hole to finish it. Reamers are designed to follow the same path as the first hole. So, it is important that the first hole is straight. The special thing about the ream is how it can take a good hole and make it a perfect one.

Yes, they are very different, and I have used both for many kinds of jobs. A hand reamer is just what its name says. It is a tool that you use by hand. You use a special handle, like a tap wrench, to turn it slowly and with great care. I often use a hand reamer for jobs that need a soft touch. This is for when I need to have a lot of control. These tools have a long, straight shank. This helps you keep them lined up straight. The front part of a hand reamer has a small taper. This helps it start cutting into the pre-drilled holes with ease. This tool is for when you need to be patient and get great precision.

A machine reamer, however, is made for strength and speed. As a different type of reamer, it is used in tools like a drill press, a lathe, or a CNC machine. These reamer tools have a special kind of shank. It is made to be held tightly in a machine’s chuck. Because they are used in a machine, they can ream holes much more quickly than I could ever do by hand. Machine reaming is the best way when you have a lot of holes to finish. They are made to handle the heat and force of working at high speeds. One common kind is the chucking reamer.

When you look at different reamers, you will see grooves that go down the side. These are called flutes. The flute is a very important part of the tool’s shape, or geometry. The flutes do two main jobs. They have the cutting edges that do the real work. They also make a path for the small bits of metal to get out of the hole. I have learned that the way the flute is made can really change how good the reamed holes turn out.

There are many different types of reamers, and the flute style is a big way to see the difference. You will see flutes that are straight. You will also see flutes that spiral around the tool. Some reamers have helical flutes, which is another way to say they have a spiral shape. The number of flutes can be different, too. More flutes often mean a smoother finish on the hole. This is because the cutting work is shared by more edges. Picking the right flute style depends on what you are cutting. It also depends on the kind of hole you want to ream.

I often grab a straight flute reamer for my everyday work. This is one of the most common reamer types you can find. The flutes on this tool are straight up and down. They are great for reaming holes that go all the way through a piece of wood or metal. The straight design pushes the cut bits of material forward. They go out of the hole. This is why they work so well for through-holes.

But, I would not use a straight flute reamer for holes that stop partway through. We call these blind holes. The metal bits can get stuck at the bottom of the hole. This can hurt the tool or the piece you are working on. These reamer tools work very well and cost less than other kinds. They are good for materials like soft steel and aluminum. For many simple reaming jobs, a straight flute reamer is a good tool you can count on.

| Reamer Type | Best For | Material |

|---|---|---|

| Straight Flute | Holes that go all the way through | Soft Steel, Aluminum |

| Spiral Flute | Holes that stop partway, hard stuff | Stainless Steel, Hard Metals |

| Helical Flute | High-accuracy jobs, very smooth finish | Special aerospace metals |

Sometimes, a straight flute is not the right tool for the job. That is when I get a helical or spiral flute reamer. Think of a screw. The lines, or threads, spiral around it. The flutes on these reamers do the same thing. This spiral shape is very good at pulling the cut bits up and out of the hole. This makes them the best tool for blind holes. There is no other way for the bits to come out.

I also like to use helical flutes when I am cutting hard materials like stainless steel. The angled cutting edge acts like a pair of scissors. This gives a much smoother cut and a better surface finish. These types of reamer tools used are needed for top-quality work. The helical shape gives a steady cutting feel. This means less shaking. The result is a cleaner and more exact hole. If you need the very best finish, a spiral flute reamer is what you want.

A chucking reamer is a real workhorse in a machine shop. I use them often in my drill press. This is a special type of machine reamer. It is made to be held in a chuck. That is why it is called a “chucking” reamer. They are used to ream holes that have been drilled already. They make them into a very precise diameter. A chucking reamer is a type of tool used in the finishing process. It is used to remove small amounts of material.

Using a chucking reamer is not hard. First, you drill the hole. Then, you take out the drill bit and put the reamer in the machine’s chuck. You have to run the machine much slower than when you were drilling. You also need to push the reamer into the hole at a steady speed. A tool called a floating reamer holder can sometimes be used. It helps the chucking reamer line up perfectly with the hole. This tool is a must-have for any kind of factory work where you need lots of sized holes to be exactly the same.

I think shell reamers are a very smart and money-saving idea. They are great when I am working on larger holes. A shell reamer is not a full tool by itself. It is only the head, or the cutting part, of the reamer. It has a hole in the middle with a taper. This empty “shell” fits onto a special holder called an arbor. The arbor has the shank that goes into the machine’s chuck.

The big plus here is saving money. When the cutting parts of the shell reamer get dull, I do not have to buy a whole new tool. I just have to get a new shell. The arbor can be used again and again with new shells. This makes the shell reamer a cheap choice for reaming big diameter holes. I have used them in CNC machining work where we were making many big parts. It is a smart way to manage the life of your tools and keep costs down.

Sometimes you do not want a hole that is straight. You might need a hole that gets a little smaller from one end to the other. This is called a taper. To make this kind of hole, you need a special type of reamer. It is called a taper pin reamer. I have used these to make holes for tapered pins. These pins are often used to line up machine parts just right. The reamer itself is shaped with a slow taper along its cutting part.

Using a taper pin reamer requires care. The reamer is pushed into a straight hole that has been pre-drilled. As it goes deeper, its growing diameter makes the hole bigger with a very exact taper. There are different kinds of standard tapers. So, you have to pick the right taper pin reamer to match the tapered pins you will use. These tapered reamers are a great example of how reaming tools can make special and exact shapes. This is a very specific but important reaming process.

Yes, you can. I have found adjustable reamers to be very handy for special jobs. An expandable reamer is a type of reamer that lets you change its cutting diameter. These reamers are usually a kind of hand reamer. They have cutting blades that are their own separate pieces. They are made of high-speed steel (HSS). These blades fit into slanted grooves in the body of the reamer.

There are nuts on each end of the blades. By making one nut loose and the other one tight, I can move the blades in the grooves. This makes the reamer’s cutting diameter bigger or smaller. This lets me make holes that have a very special, non-standard diameter. Adjustable reamers are great for fixing things. They are also good when you need just one hole of a very specific size. You have to be careful to adjust them the same on all sides. This will keep the hole nice and round. They are a great tool to have when you are in a difficult situation.

Picking and using the correct reamer is a skill I have learned over many years. It is all about picking the right tool for the material and the job. First, you have to think about the hole you are making. Does it go all the way through, or does it stop partway? This will help you pick between a straight or spiral flute style. Next, think about the material. For soft things, an HSS (high-speed steel) reamer is often good enough. For harder things like stainless steel, you will want to use carbide reamers. Carbide is much stronger and will last a lot longer.

Here is a quick guide on how to use a reamer:

I am sure that if you follow these steps, you will be able to successfully use a reamer. The whole point of reaming is to improve the precision of a pre-drilled hole. The right type of reamer will help you get a perfect fit and finish in your machining work. From milling tools to drill bits, every tool has its own job. The reamer is the expert for that final, exact sizing. Picking the right reamer for your application is the first step to doing a great job.