Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Are you looking for a powerful and flexible machine for your workshop? Vertical milling might be just what you need! This guide will help you understand what vertical milling is, how it works, and why it could be perfect for your projects.

Supports uploading of the following file formats: .STEP .STP .SLDPRT .STL .IPT .3MF .3DXML .PRT .SAT .DXF .X_T .X_B .JT .CATPART

Istar Machining's years in the industry

The size of Istar Machining's factory

Our CNC equipment count

Istar's number of skilled machinists/operators

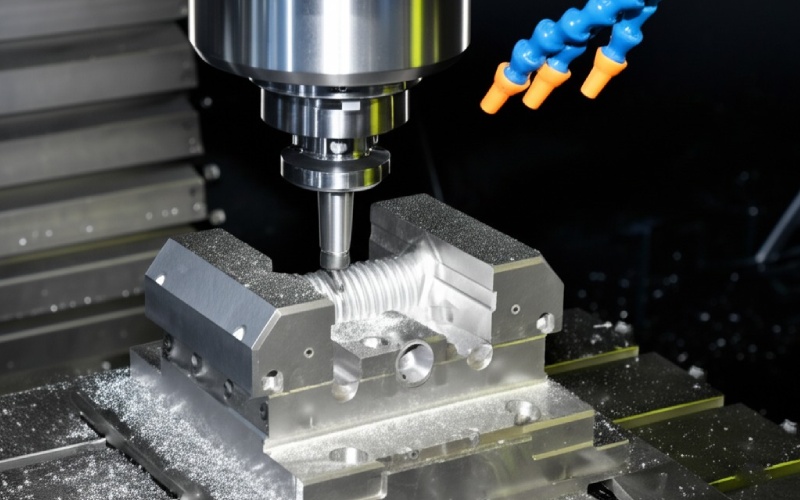

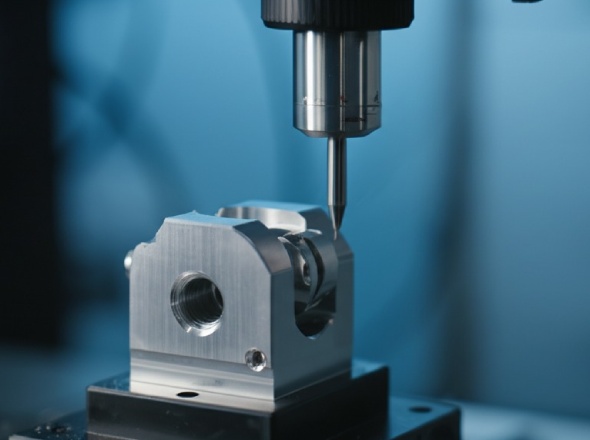

Vertical milling is a type of machining where the cutting tool moves up and down, with its axis pointing straight down into the material. The tool spins fast while moving across the work surface to cut away material and make precise shapes.

At Istar Machining, we use vertical milling to create parts with amazing accuracy. The main part of a vertical mill is the spindle – that’s what holds and spins the cutting tool.

Here’s why shops big and small love vertical milling machines:

As one of our machine operators says: “With vertical mills, what you see is what you get – there’s no guessing what’s happening under the cutter.”

| Feature | Vertical Milling | Horizontal Milling |

| Tool Position | Points down at workpiece | Points across workpiece |

| Best For | Flat surfaces, pockets, drilling | Heavy material removal, slots |

| Visibility | Excellent – see cutting action | Limited – tool may be hidden |

| Setup Time | Faster for simple jobs | Longer setup but faster for big jobs |

| Floor Space | Compact (6’x4′) | Larger (8’x6′) |

| Learning Curve | Easier for beginners | Steeper learning curve |

Our advanced Vertical Milling capabilities allow us to machine a diverse range of materials with precision and efficiency. Below are some of the most common materials we work with, tailored to meet your specific project needs.

Metals

(Common Grades: 6061, 7075, 5052, 2024, 6063, 5083) is lightweight, corrosion-resistant, has excellent thermal and electrical conductivity, and is very machinable. It offers a great strength-to-weight ratio.

Good for:

Why customers love it: “It provides an outstanding balance of strength, weight, machinability, and cost-effectiveness, making it versatile for countless prototyping and production applications. Easy to finish (anodizing, painting).”

(Common Grades: 303, 304/304L, 316/316L, 410, 416, 420, 17-4 PH) offers high strength, excellent corrosion resistance, heat resistance, and durability. Machinability varies significantly by grade (303/416 are easier, 304/316 are tougher).

Good for:

Why customers love it: “Its superior resistance to corrosion and staining, coupled with high strength and aesthetic appeal, makes it ideal for demanding environments and applications where hygiene or appearance is critical.”

(Common Grades: 1018, 1020, A36) is a cost-effective ferrous metal known for its good machinability, weldability, and strength. It is susceptible to rust if not coated or treated.

Good for:

Why customers love it: “It’s the go-to affordable steel option. Readily available, easy to machine and weld, and provides sufficient strength for a vast range of non-corrosive applications.”

(Common Grades: 4140, 4340, 8620) contains alloying elements (like chromium, nickel, molybdenum) that enhance properties like hardness, strength, toughness, and wear resistance compared to carbon steels. Often requires heat treatment to achieve desired properties.

Good for:

Why customers love it: “Offers significantly improved mechanical properties over mild steel, enabling parts to withstand higher loads, greater wear, and tougher conditions, especially after heat treatment.”

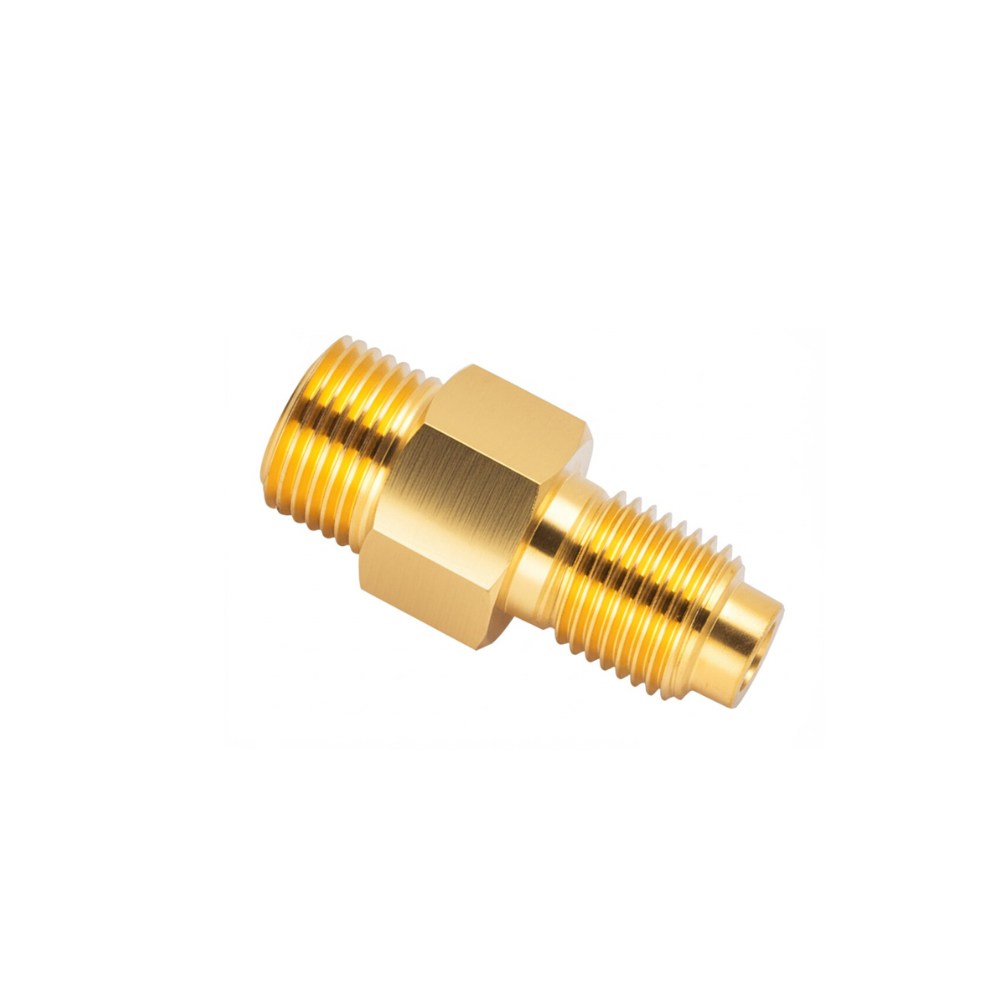

(Common Grades: C360 – Free-Cutting Brass) is a copper-zinc alloy prized for its exceptional machinability (often the benchmark), good corrosion resistance, excellent electrical conductivity, and attractive gold-like appearance.

Good for:

Why customers love it: “It’s incredibly easy and fast to machine, leading to lower costs for complex parts. It also offers good corrosion resistance and a desirable aesthetic finish.”

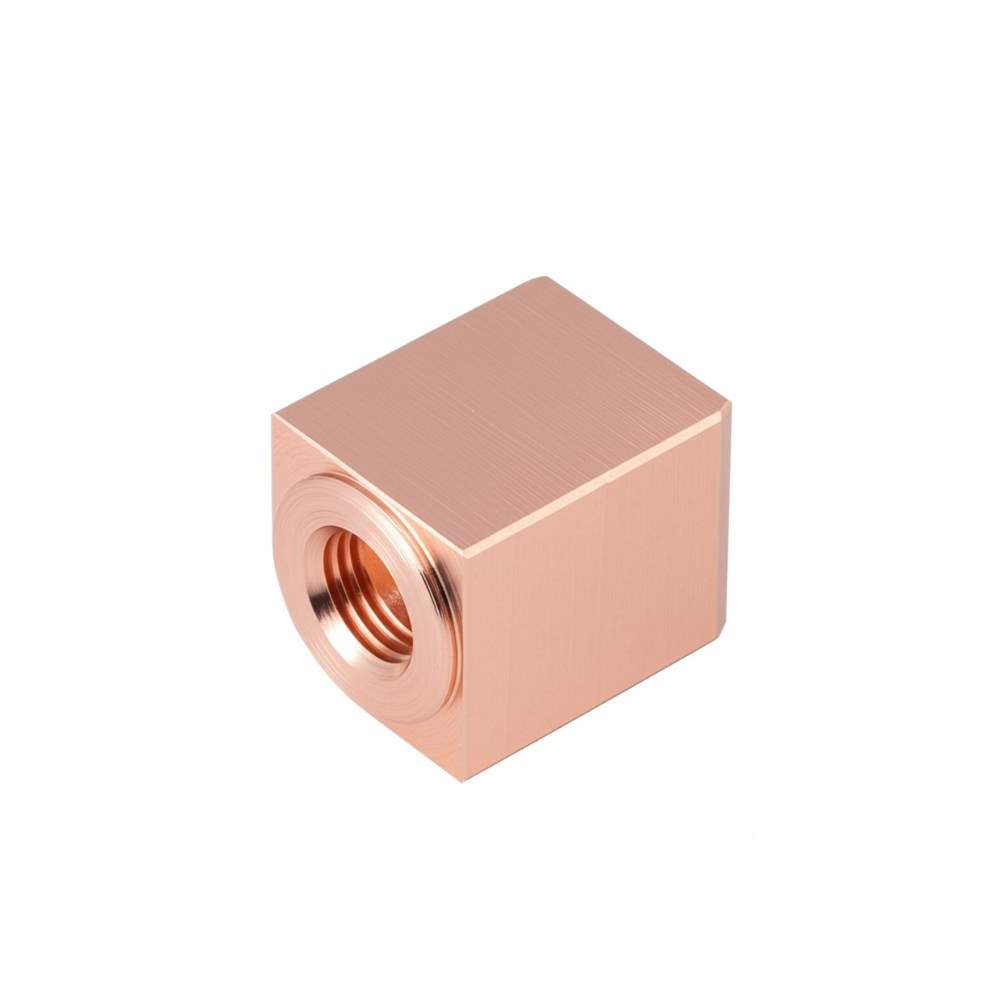

(Common Grades: C101 (OFHC), C110 (ETP)) is renowned for its outstanding electrical and thermal conductivity, second only to silver. It also has good corrosion resistance and ductility. Can be somewhat ‘gummy’ to machine compared to brass.

Good for:

Why customers love it: “Unbeatable electrical and thermal performance makes it essential for specific conductivity applications. It also has good formability and corrosion resistance.”

(Common Grades: Grade 2 (Commercially Pure), Grade 5 (Ti-6Al-4V)) boasts an exceptional strength-to-weight ratio, outstanding corrosion resistance (especially against saltwater and chemicals), and biocompatibility. It is notoriously difficult and expensive to machine.

Good for:

Why customers love it: “For applications demanding high strength, low weight, and superb corrosion resistance, especially at elevated temperatures or in biological environments, titanium is often irreplaceable despite its cost.”

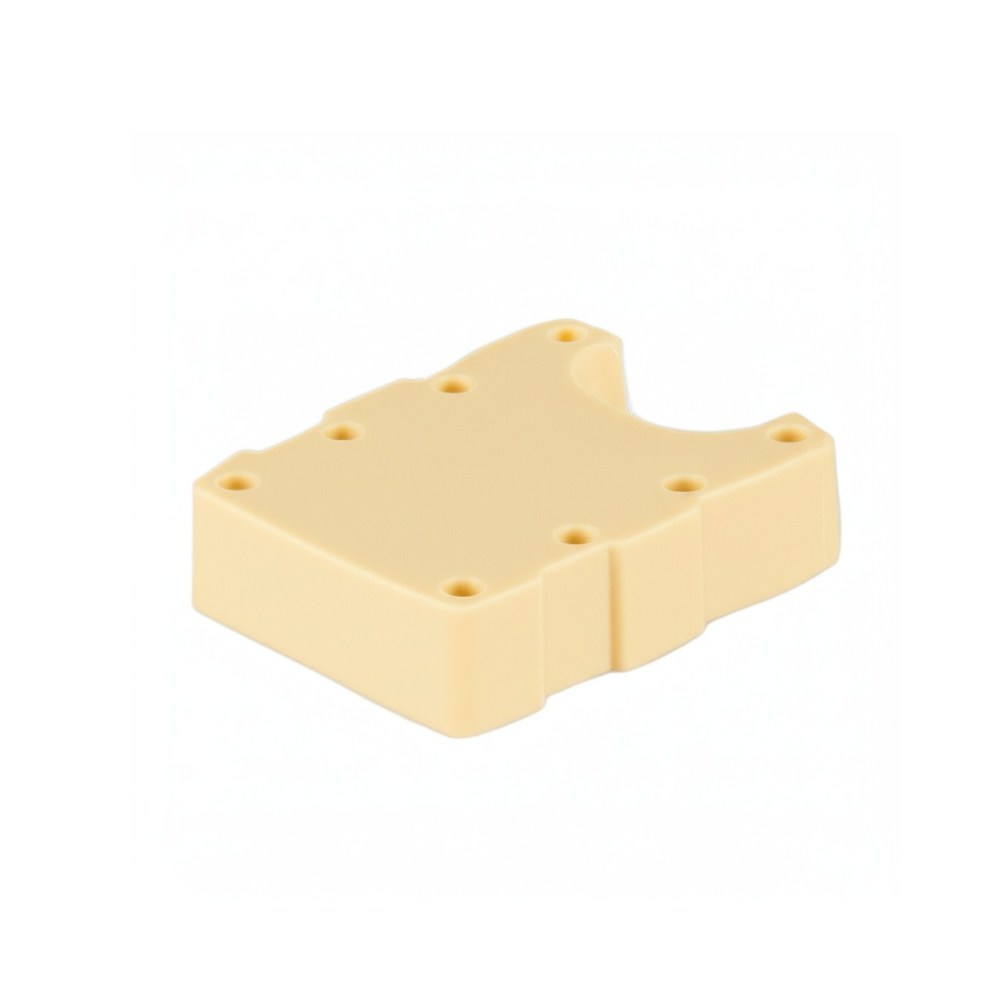

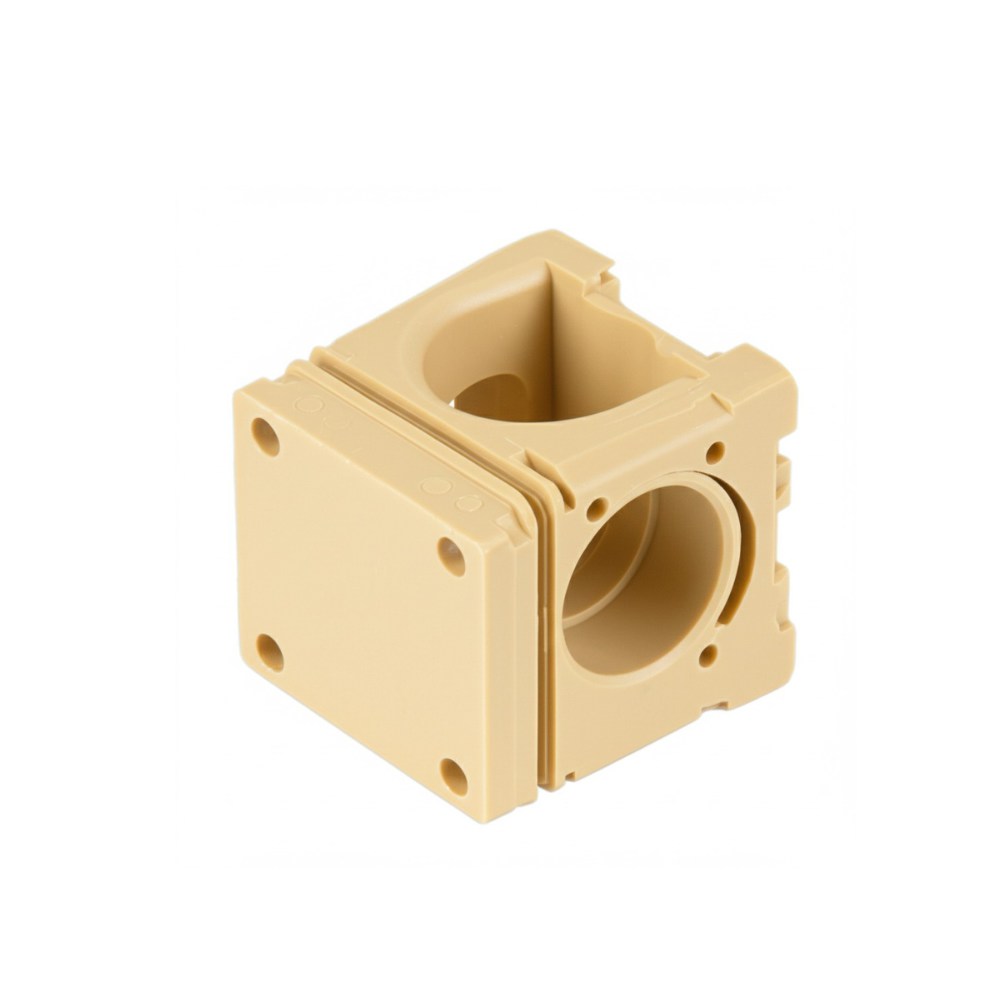

Plastics

(Common Grades: Standard extrusion/molding grades) is a common thermoplastic polymer known for its good balance of impact resistance, toughness, stiffness, and ease of machining. It’s relatively inexpensive and available in various colors.

Good for:

Why customers love it: “A versatile, cost-effective plastic that’s easy to machine and finish (can be glued, painted). Offers good toughness for general-purpose applications.”

(Common Grades: Copolymer (e.g., Celcon®), Homopolymer (e.g., Delrin®)) is an engineering thermoplastic characterized by its high stiffness, low friction, excellent dimensional stability, good wear resistance, and resistance to moisture and many chemicals.

Good for:

Why customers love it: “It’s naturally slippery (low friction), strong, stiff, and machines beautifully to tight tolerances. Excellent for moving parts or components needing dimensional stability.”

(Common Grades: Nylon 6, Nylon 6/6, often Glass-Filled variants) is known for its toughness, high wear resistance, good abrasion resistance, and good chemical resistance (especially to oils and fuels). It tends to absorb moisture, which can affect dimensional stability and mechanical properties.

Good for:

Why customers love it: “Offers great toughness and wear resistance at a reasonable cost, making it suitable for many mechanical components, though moisture absorption needs consideration.”

(Common Grades: Machine Grade, Optical Grade) is a strong, extremely tough thermoplastic with high impact resistance, good temperature resistance, and natural transparency. It maintains rigidity over a wide temperature range.

Good for:

Why customers love it: “Incredibly durable and impact-resistant (‘shatterproof’), offers clarity options, and holds up well under moderate heat. Great for tough, transparent parts.”

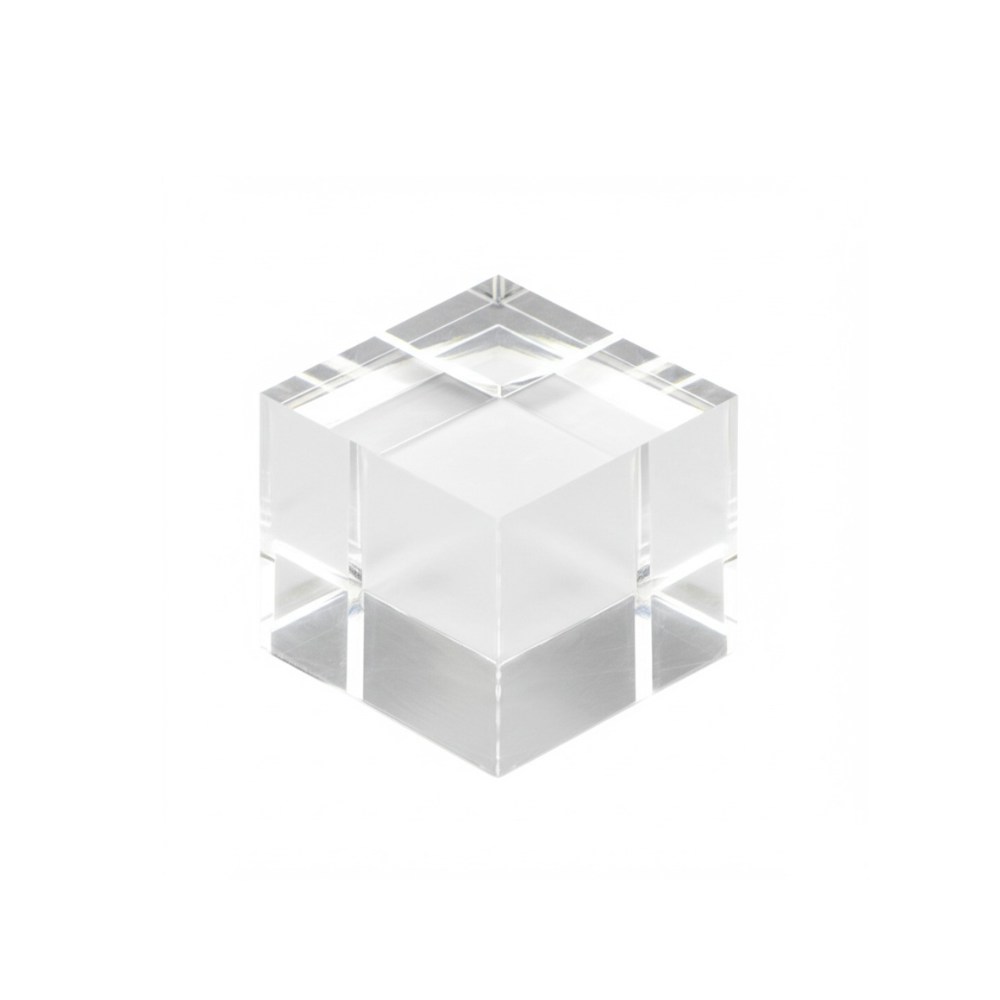

(Common Grades: Cast, Extruded) is a rigid thermoplastic known for its excellent optical clarity, weather resistance, and ease of machining and polishing. It is more brittle and less impact-resistant than polycarbonate.

Good for:

Why customers love it: “Offers glass-like clarity at lower cost and weight, is easy to machine to a smooth finish, and polishes well. Excellent for aesthetic and optical applications.”

(Common Grades: Unfilled, Glass-filled, Carbon-filled, Bearing Grade) is a high-performance engineering thermoplastic offering an exceptional combination of properties: high strength, stiffness, high-temperature resistance (continuous use >250°C), excellent chemical resistance, wear resistance, and inherent flame retardancy. Biocompatible grades exist. It is expensive.

Good for:

Why customers love it: “The ultimate plastic for extreme conditions. It maintains its strength, stiffness, and chemical resistance at very high temperatures where other plastics fail.”

(Common Grades: Standard, Reprocessed, various enhanced grades) is known for its extremely high abrasion resistance, very low coefficient of friction, high impact strength, and good chemical resistance. It has relatively low stiffness and can be challenging to machine to very tight tolerances due to thermal expansion and flexibility.

Good for:

Why customers love it: “Outstanding resistance to wear and abrasion, very slippery surface, and excellent impact toughness. Ideal for applications involving sliding contact or impact.”

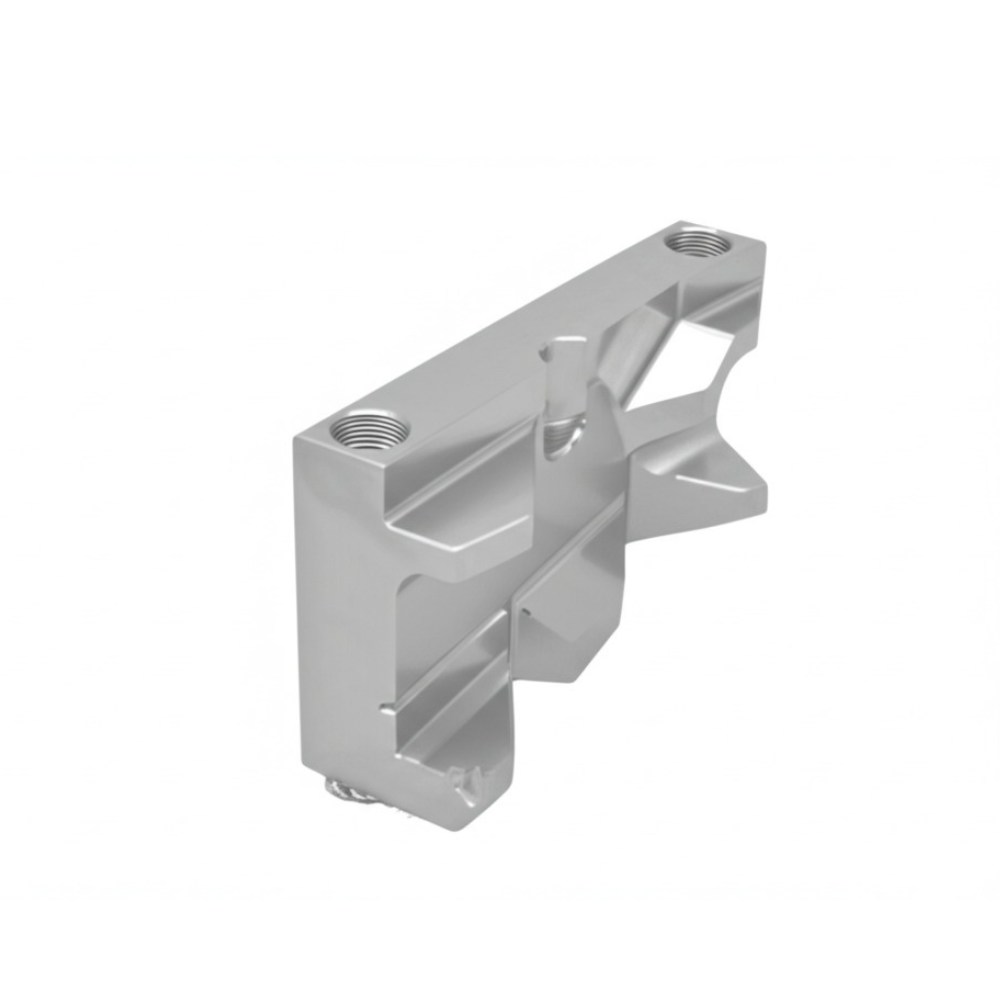

Our customers use vertical milling for all kinds of cool projects:

We make lightweight parts for planes using high-speed spindles that can reach 30,000 RPM for aluminum CNC machining. The surface finish is so smooth it looks like a mirror!

Our vertical mills create surgical tools with tolerances of ±0.0005". That's five ten-thousandths of an inch - crazy precise!

Engine blocks need many precise holes and flat surfaces. Vertical mills make this work easy and accurate.

Custom designs in brass and steel with amazing detail are possible with micro-tooling on vertical mills.

Vertical milling machines offer the perfect blend of precision, versatility, and value. They can handle so many different jobs.

Whether you’re creating prototypes, making small production runs, or crafting one-of-a-kind parts, a vertical mill delivers the accuracy you need without breaking the bank.

At Istar Machining, we’re proud to offer top-quality vertical milling services as part of our comprehensive CNC machining service lineup. Our experienced team can help bring your designs to life with precision and care.

Ready to learn more about how vertical milling can help with your next project? Contact us today for a free consultation!

Yes! With the right carbide tools and proper speeds, vertical mills can work with hardened steel up to Rockwell 60C hardness.

Bed mills have a fixed column and moving table, while turret mills allow the head to move for more flexibility.

Absolutely! Vertical mills can create amazing wood projects, though dedicated CNC wood machining equipment might be better for very large projects.

Yes! In fact, vertical mills excel at drilling operations because of their up-and-down motion.

Let’s skip the theory and talk about what strict tolerances actually do to the price of a CNC part — on the

CNC machining buyers usually optimise unit price, cycle time, maybe tooling. Then the first 40-foot container of heavy machined parts

You’ve got a STEP file, a deadline, and one question: “For this one prototype, do I send it for CNC machining or