Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

In this article, I’m going to pull back the curtain on the world of laser engraving. I’ll explain what it is, how it works, and what you can do with it. If you’ve ever been curious about how those amazing custom designs are made on everything from tumblers to signs, you’ve come to the right place. I’ll make the process of laser engraving simple and clear for you.

Let’s start with the basics. In simple terms, laser engraving is a process where a powerful laser beam is used to change the surface of an object. Think of it like a highly focused, super-hot light that carves away tiny bits of material. This process of laser engraving doesn’t use ink or tool bits. Instead, the laser removes material to create a design that you can see and feel. The engraving is permanent because it’s physically part of the object. When you laser engrave something, you are creating a mark that won’t rub off or fade over time.

The goal of laser engraving is to remove material from the surface to create a cavity. This is different from other methods. For instance, when you engrave by hand, you use a sharp tool. With a laser, the heat does all the work. The result of laser engraving is a precise and clean mark. This technique is often used for everything from personalizing gifts to marking industrial parts. The engraving can be deep or shallow, depending on the settings you use. To laser engrave is to make something uniquely yours. It’s a powerful way of creating a permanent mark.

You might be picturing a giant, complex machine, but the idea behind it is quite simple. A laser engraving machine uses a focused beam of light to do its job. Inside the machine, a laser system creates a powerful laser beam. This beam is aimed at a series of mirrors, which direct it to the laser head. Inside the head, a special laser lens focuses the light into a tiny, powerful point. This focused laser beam is what does the actual engraving. The laser hits the material to be engraved and its intense heat causes the material’s surface to vaporize.

The machine is controlled by a computer. You create a design in a program, and the computer tells the laser head where to move. As it moves back and forth, the laser turns on and off very quickly, using short pulses of light. Where the laser vaporizes the material, it leaves behind an engraving. This is how laser engraving removes material with such amazing detail. You can laser engrave very simple text or incredibly intricate designs. The whole engraving process is fast and automatic. The ability to engrave this way has changed many industries. Using a laser to engrave is a high-tech art form.

People often use these terms together, but they are different. The main difference is what happens to the material. Laser engraving is a process where the beam physically removes the material from the surface to create a deep mark. When you run your finger over a part that you laser engrave, you can feel the depth. The engraving is cut into the material.

Laser marking, on the other hand, doesn’t really remove material. Instead, laser marking uses a lower-powered beam to cause a chemical change or discoloration on the surface. It creates a high contrast mark without changing the texture much. This is often used for things like serial numbers or barcodes, which is a type of product marking. Then you have etching. To etch is basically a very shallow form of engraving. The laser melts the surface, causing it to expand and create a raised mark. So, while you engrave by vaporizing material away, you etch by melting it. Whereas laser marking is on the surface, engraving and to etch go deeper. These different marking systems are all useful.

When you decide you want to laser engrave something, you need the right tool. There are a few main types of engraving machines, and they are suited for different jobs. The two most common are CO2 lasers and fiber lasers. A fiber laser is the powerhouse for metal. If you want to do engraving metal, a fiber laser is your best friend. It has a specific wavelength that works great on steel, aluminum, and other metal alloys. This makes it perfect for industrial marking and metal engraving.

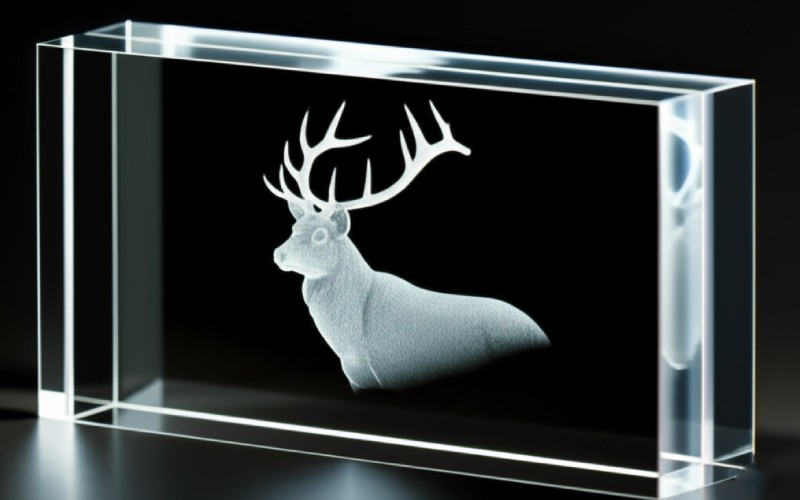

Then there are CO2 lasers. These are more of an all-around machine. They are perfect for engraving materials like wood, acrylic, glass, leather, and stone. The wavelength of a CO2 laser is great for organic materials. So if you want to engrave a wooden sign or do some custom glass engraving, this is the type of laser engraver you’d use. There are other types, but these two cover a wide range of materials. Choosing the right laser machine is the first step to getting a great engraving. The types of laser engraving you can do are defined by your machine.

So, how does a project go from an idea to a finished product? The laser engraving process is pretty straightforward. First, you need a design. You can create one using design software like CorelDRAW or Adobe Illustrator. This is where you lay out your text or images, creating the engraving patterns you want. Your design is then sent to the laser engraving system.

Next, you prepare the machine. You place your material inside the laser machine. You have to set the correct speed and laser power for the material you are using. These settings for different materials are very important for getting good engraving quality. Once you hit ‘start’, the magic begins. The laser engraver’s head moves over the material, and the laser engraves your design onto it. The machine follows your digital file perfectly, creating a beautiful engraving. After the laser engraving is done, you just need to clean off any residue. It’s a fun process to watch.

In a perfect world, we could laser engrave anything we wanted. But in reality, the answer is no. Not all materials are safe or suitable for laser engraving. The ability to engrave a material depends on how it reacts to the laser beam’s heat. Some materials don’t react well. For example, some plastics will just melt into a gooey mess instead of creating a clean engraving. The challenge is to match the laser with the right material.

The most important thing to know is that some materials are dangerous to laser engrave. A major example is PVC (polyvinyl chloride). When you try to engrave it, engraving pvc releases harmful chlorine gas. This gas is toxic to you and can destroy your expensive engraving machines. This is why it’s critical to know what you are cutting or trying to engrave. Always check the material’s properties before you laser engrave it. Safety in the field of laser engraving is a top priority. Use of a laser requires knowledge.

While you can’t engrave everything, the list of materials that can be engraved is still huge. This is what makes laser engraving so versatile. You can work with a variety of materials. For CO2 lasers, popular choices include materials like wood, plywood, MDF, and even cardboard. You can get beautiful results on acrylic, making signs and art pieces. Leather is another great material to laser engrave, giving it a nice, branded look. You can also engrave stone, ceramic, and glass.

For metal, it gets a bit more specific. As I mentioned, you usually need a laser of the fiber type for engraving metal. A fiber laser can easily do engraving on stainless steel, aluminum, and titanium. It’s also possible to laser engrave anodized aluminum with a CO2 laser, as the laser just removes the colored coating. The list goes on, and people are always experimenting with new things to engrave. This flexibility is what makes laser technology so exciting for both hobbyists and businesses. Laser engraving metals is a huge market.

Safety is a huge deal when you are using a laser powerful enough to vaporize material. The laser beam itself is incredibly strong and can cause instant and permanent eye damage if you look at it. That’s why laser engraving machines have protective covers, and operators should always wear safety glasses. The engraving may seem safe, but you must respect the power of the laser.

Another major safety concern is the fume that is created during the engraving process. When the laser hits the material, it creates smoke and particles. This fume can be smelly and, depending on the material, toxic. A good ventilation or air filtration system is not just a nice-to-have; it’s essential for a safe work environment. The fume must be directed away from the operator. Proper safety turns laser engraving work from a risk into a controlled, productive process.

With so many ways to decorate or mark objects, why is laser engraving so popular? There are a few big reasons. First is precision. A laser machine can create incredibly detailed work. You can engrave tiny text and intricate designs that would be impossible with other engraving methods. The engraving quality is unmatched. Second is speed. For many jobs, laser engraving is much faster than traditional engraving, making it great for production.

Another benefit is that it’s a non-contact process. Only the laser beam touches the material, so there’s no tool wear and tear. You can engrave delicate items without clamping them down hard. The engraved areas are clean and permanent. Laser marking systems and engraving and cutting systems offer a level of detail that is hard to beat. The result of laser engraving is a professional, high-value look. This laser engraving technology helps products stand out.

Feeling inspired to laser engrave something? Getting started is easier than you think. You don’t need to buy a big laser engraver right away. A great first step is to find local engraving services or a community makerspace. These places have the equipment and often offer training. You can bring in a simple design and a piece of material like wood or acrylic and see how the process works firsthand.

Start with a simple project, like engraving your name on a keychain or a small design on a piece of scrap wood. This will help you understand how different settings affect the engraving depth and look. You’ll learn how to prepare a file and see how the laser system brings it to life. Once you do your first engraving, you’ll see the amazing potential. From there, you can explore more complex projects and materials. The world of laser engraving is waiting for you to make your mark. The created by laser engraving products are very satisfying.