Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

This article will tell you about a special cleaning method for steel. This method is called passivation. It is a great way to stop rust from ever starting. If you use parts made from stainless steel, this is something you should know about. Keep reading to see how this easy chemical treatment can keep your metal safe. It can save you money and help you make your products stronger and better. We will use simple words to explain it all. The passivation process is a very important part of making steel strong and able to last a long time.

What is this thing people call passivation? You can think of it as a super-strong, invisible shield for steel. Passivation is a chemical treatment. It makes stainless steels much better at fighting off rust. The passivation process is a final step. It is done after a metal part has already been made. Why is this so important? It is because stainless steel naturally resists corrosion, but it can still get some weak areas. The manufacturing process, like when you cut or bend the steel, can leave very small pieces of iron on the surface of a stainless steel part. These little spots are the places where rust really likes to begin.

This is where the passivation process helps out. Passivation is a process that cleans away these weak spots. It helps the steel make a tough, clear shield. This shield is extremely thin, but it is also very strong. It works to keep air and water from touching the metal underneath. This is how it stops rust before it can form. So, passivation helps your steel parts last for a much longer time. It is a very important step for any metal product that needs to be high quality. This chemical passivation makes sure the steel will work its best.

So, how is this amazing shield created? It is all about how chemicals work, but it is not hard to understand. Stainless steels have a special material inside them known as chromium. Chromium really likes oxygen. When the chromium touches the oxygen in the air, it makes a layer that is very thin, strong, and does not change. This is called passivation. This new layer is a protective oxide layer. It covers all of the metal surface. This shield, which is also called a passivation layer, does not react much with other chemicals. You can think of it like a coat of paint that will never chip or peel off.

The process of passivation helps this natural shield to grow even thicker and stronger. It does this by cleaning the surface of the metal. The chemical treatment gets rid of any loose iron and other things that should not be there. This leaves behind a clean surface with plenty of chromium that is ready to mix with the air. The formation of the oxide layer happens very, very fast. This brand new, strong oxide film is what gives stainless steels their wonderful power to fight against rust. The effect of passivation is a metal part that will last a lot longer.

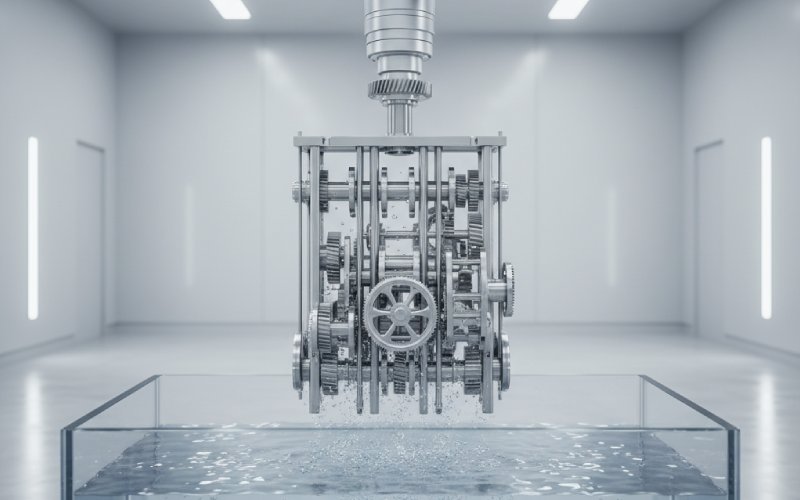

A good passivation procedure, or way of doing things, has a few easy but key steps. It is a bit like washing your hands before you have a meal. You must do it the correct way for it to work well. The main goal is to remove the surface contamination. This means getting rid of dirt and other unwanted things on the surface so the steel can make its own shield.

Here are the basic steps for the cleaning and passivation of stainless steel parts:

When you need to passivate stainless steel parts after machining, you have an option to choose from. The two acids that are used most often are nitric acid and citric acid. Both do a very good job of cleaning iron from the surface, but they have some differences. Your choice is based on the kind of steel you have and what you need it for. An expert in passivation work can help you pick the right one.

Nitric acid is a choice that has been used for many years. It is very powerful and works great on many different kinds of stainless steels. The passivation process uses nitric acid to take away iron very quickly. But, nitric acid can be dangerous to be around. It can also let out bad gases. Using stainless steel with nitric acid must be done with special care.

Citric acid is a newer choice, but it is being used more and more. The citric acid passivation method is much safer for workers and for our world. Citric acid is natural and comes from fruits like lemons. It is a much less harsh chemical treatment. The citric acid process is excellent for many grades of stainless steel. It often works just as well as nitric acid. Many businesses now like to use citric acid because it is safer and easier to use for passivating stainless steel.

| Feature | Nitric Acid Passivation | Citric Acid Passivation |

|---|---|---|

| History | Used for a long, long time; a classic method. | A newer, more modern way of doing it. |

| Safety | Can be dangerous; makes bad fumes. | Very safe; breaks down naturally and is good for Earth. |

| How Well it Works | Works very well on many types of stainless steels. | Also works very well, and is great for some steel types. |

| Cost | Can cost more because of safety rules. | Often costs less to use and get rid of. |

To skip the passivation of stainless steel is a very big mistake. You may feel like you are saving some time or some money, but it will cause problems for you later on. When you make a part from stainless steel, very small bits of other metal can get stuck on its surface. This often happens when the steel is being cut, ground, or moved around. This surface contamination is like leaving a door wide open for rust to come in. The little pieces of iron will begin to rust very fast as soon as they get wet.

This rust can easily spread. It can leave ugly stains on your nice and shiny stainless steel. Even worse, it can make a tiny hole where even more serious rust can start to grow. This makes the metal look bad and also makes it weaker. The main reason for using expensive stainless steel is to stop rust! If you decide to skip the passivation treatment, you lose that big benefit. The lack of chemical reactivity that makes stainless steel so great is lost. It will significantly affect the stainless steel part’s ability to last a long time.

People can sometimes mix up passivation and pickling. Both of them use acid to treat steel, but they are for two very different jobs. Knowing the difference between passivation vs pickling is important for anyone who works in the metal finishing field. The way they are done is similar, but their goals are not the same.

Pickling is a very heavy-duty cleaning process. It uses very strong acids to take off a thin layer of steel from the top. This is done to get rid of thick scale from welding, marks from work, or rust that is already there. You can think of pickling like a very deep cleaning that takes off the top skin of the metal. Pickling and passivation are sometimes done one after the other.

Passivation, however, is a much softer process. The passivation process does not take away the steel itself. It only cleans off tiny pieces of iron and other dirt from the very top. Its main job is to help the steel make its own shield for protection. Passivation is performed to make the natural rust-fighting power of the metal even better. It is a finishing process to prevent corrosion, not to get rid of it once it has already started.

Almost every part that is made from stainless steels can be helped by this treatment. Any time that steel is cut, bent, welded, or worked on, it should be passivated. For this reason, passivation is a post-fabrication process, meaning it is done after the part is made. This treatment is like a way to make sure the part is good quality.

Here are some examples of where passivation is the use of a very smart process:

After you passivate stainless steel parts, how can you be sure the job was done the right way? You are not able to see the protective layer. It is invisible to your eyes. That is why there are special tests that are used to check effectiveness of the process, or how well it worked. These tests check to see if there is any leftover loose iron on the surface of the metal. If the test finds no loose iron, it means the passivation layer is strong.

A common test is to put a special liquid on the steel. If the liquid changes its color, it means that there is still iron on the surface. That means the part did not pass the test. Another kind of test measures how well the steel can fight rust in a special chamber that is made to cause rust. There are clear rules and passivation specifications that good shops always follow. These rules are in place to make sure that the stainless steel passivation is done correctly every single time. This check for quality is a very important part of the service.

That is a very good question. There are many different kinds of stainless steels. These different kinds are called grades. Some grades are better for bending, some are made to be stronger, and some are better at fighting off rust. The good news is that the passivation process works for most of these grades of stainless steel. The process that is performed can be adjusted a little bit to work best for each kind of steel.

For instance, some stainless steels can be damaged easily. If you use a strong nitric acid bath on them, it might harm the surface. For these kinds of steel, a softer citric acid bath is a much better option. The amount of time the part stays in the acid and the heat of the bath might also be changed. An expert in surface passivation will know the perfect recipe for every kind of steel. This special knowledge makes sure the formation of the oxide happens in a perfect way without hurting the metal. The right kind of passivation of corrosion protection is based on using the right method for the right kind of metal.

So, why should you do all of this? It is because the good things you get are very big. A proper chemical passivation service will give your stainless steel parts a life that is much longer and better. Passivation offer many wonderful advantages. It is a smart way to spend money to improve the quality of your product. The passivation is a chemical step that brings true value.

Here are the main good things that you will get:

New technology has also made the process even better. There are things like automated passivation. This uses machines to control the process perfectly so it is the same every time. A good metal finishing process to prevent rust is a very wise choice.

You have now learned a lot about the passivation process. It is a very important step for making parts from stainless steel strong and long-lasting. Here is a short list of the most important things to know.