Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

This article will tell you about a great plastic called PMMA. It is also known as acrylic or by its full name, polymethyl methacrylate. You will learn how it is made. You will find out what it is used for and why so many people like it. This guide will help you figure out if PMMA is the right material for what you want to do. If you are looking for a material that is strong and clear, this article has all the answers you need. This is everything you need to know about PMMA.

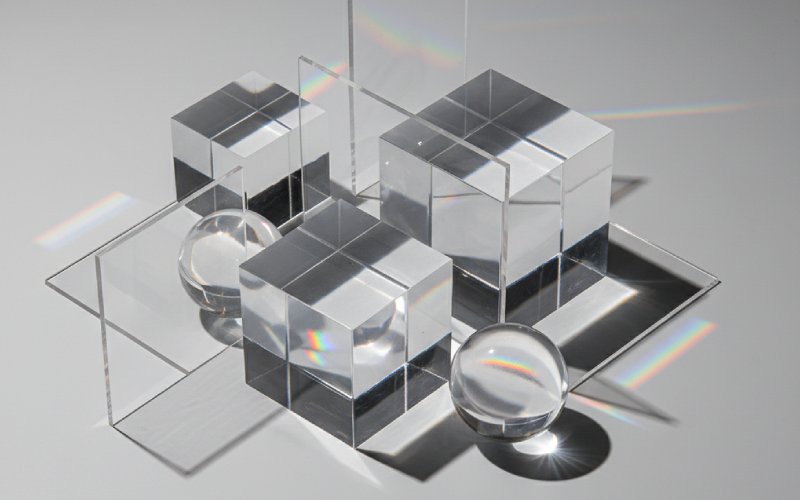

PMMA is a short name for a very long word: polymethyl methacrylate. You might know this material by its other, more common names, like acrylic or acrylic glass. It is a kind of plastic that is tough, not heavy, and very clear. You can think of it like a see-through plastic that you can use instead of glass. Because it is so easy to see through, PMMA is a very popular material. People like it for its good looks and its strength. PMMA is a versatile material, which means it can be used for many different products that we see every day.

This cool material is a thermoplastic. This means if you heat it up, it becomes soft and you can bend it into different shapes. When it cools down, it gets hard again. You can do this more than once. This makes PMMA easy to work with when making all sorts of things. PMMA is a synthetic polymer. This just means it is a material made by people in a lab. Scientists make it by linking lots of small molecules together in a long chain. The way these chains are made gives the acrylic its special features.

The properties of the material make it a good pick for many different jobs. It is much stronger than glass but weighs a lot less. The weight of PMMA is about half that of glass. This makes it simpler to carry and put in place. PMMA is also a great alternative to glass because it does not break into tiny, sharp bits. This makes PMMA a safer option for things like windows, safety shields, and store displays. The PMMA polymer is a really useful kind of plastic.

To make PMMA, you start with a liquid chemical called methyl methacrylate. This is the main ingredient for the acrylic. To change this liquid into a solid plastic, a special method called polymerization is used. In the polymerization process, many single molecules of methyl methacrylate connect together. They form long chains, kind of like linking many paper clips to make a long string. This process is what creates the strong polymer that we call PMMA.

There is more than one way to do this polymerization of methyl methacrylate. A common way is to pour the liquid methyl methacrylate into a mold. After that, a chemical is added to get the process started. The mold is heated up, and the liquid slowly hardens into a solid sheet of PMMA plastic. This is how big, clear acrylic sheets are often made. The whole process must be watched very closely to make sure the final PMMA product comes out just right.

The result of making PMMA is a transparent thermoplastic. This means the plastic is clear and can be heated and shaped again. The finished PMMA product can be made in many different forms. It can be turned into sheets, long sticks, or tubes. It can also be ground up into very small beads. These beads can be melted down and pushed into molds to make all kinds of shapes. This is done with methods like injection molding. Because it can be shaped in so many ways, PMMA is widely used.

When you go to buy PMMA, you will probably find two main kinds: cast acrylic and extruded acrylic. They are both made from the same stuff, but they are made in different ways. The way they are made changes some of the properties of PMMA. If you know the difference, it will help you pick the best type of acrylic for your project.

Cast acrylic is made when the liquid methyl methacrylate is poured into a mold. This is often done between two flat pieces of glass. The liquid then hardens using the polymerization process. This way of making it creates a very high-quality sheet of PMMA. Cast acrylic is stronger and has better optical clarity than the other kind. It is also harder to scratch. Because it is made in a flat mold, it is just as strong in every direction. PMMA is sometimes made this way for projects that need to be top quality.

Extruded acrylic is made with a method called extrusion. For this, small PMMA pellets are melted down. Then, they are pushed through a machine that squeezes them out into one long, continuous sheet. This way is quicker and costs less than casting. That is why extruded acrylic is usually cheaper. But, extrusion can make the acrylic sheet a little weaker in one direction. It is also a bit easier to scratch and might have tiny specks inside. For many projects, though, extruded PMMA sheets are a great choice.

Acrylic glass is a wonderful shatter-resistant alternative to glass. A main reason people pick acrylic instead of glass is for safety. When glass breaks, it shatters into lots of sharp, dangerous pieces. PMMA, on the other hand, is much harder to break. If it does break, it usually just cracks into a few large pieces with dull edges. This makes it a much safer material for places where things might get broken, like in schools or busy public spots.

Another big plus is how much it weighs. PMMA is often used as a lightweight alternative to glass. It weighs less than half of what the same size piece of glass would weigh. This makes PMMA sheets much easier to lift, carry, and set up. This is very helpful for big projects, like putting in large windows or building big fish tanks. Using a lighter material can also save money on the frames needed to hold it up.

Last, acrylic offers a lot for its price. Some special kinds of PMMA can cost a lot, but regular acrylic is usually cheaper than glass. It is also easier to cut and make into different shapes than glass is. You can drill holes in it or cut curves into it with normal tools. Because it is so easy to change, you can use PMMA to make special shapes and designs that would be very hard or costly to make with glass. For these reasons, PMMA is compatible with many different project ideas.

The optical properties of PMMA are one of the things it is best known for. PMMA has amazing optical clarity. This means light can go right through it very easily without getting bounced around. In fact, a clear sheet of PMMA lets about 92% of the light you can see pass through it. That is even more light than a normal pane of window glass lets through. This high amount of transparency is why PMMA looks so perfectly clear.

This great transparency makes acrylic perfect for any job where you need to see through something very well. This can be for things like display cases in a museum, windows on an airplane, and see-through safety screens. The material does not have the slight green color that you can see in thick glass. This means colors look just as they should when you see them through a clear acrylic sheet. This makes transparent PMMA very useful for store displays and for framing pictures.

On top of being clear, PMMA also bends light in a useful way. This is important for optical tools. PMMA is used to make things like lenses and light guides for cameras and science equipment. The optical properties of this plastic are so good that it is often used as a safe and light replacement for glass in many optical jobs.

When people need a strong and clear plastic, they often look at PMMA and polycarbonate. They are both great materials, but they have important differences. The biggest difference is how well they can take a hit. Polycarbonate is incredibly strong. It is almost impossible to break and is used for things like bulletproof windows and police shields. PMMA is strong too, but not as tough as polycarbonate. It is more stiff, but it can crack or break if it gets hit very hard.

But PMMA is better in other ways. It has better optical clarity and transparency than polycarbonate. PMMA is also harder to scratch. Over time, polycarbonate can get covered in tiny scratches that make it look foggy. PMMA stays clear for a longer time. Also, PMMA does not turn yellow from the sun as fast as regular polycarbonate does. This makes PMMA a better pick for outdoor signs and windows where how it looks is important.

Price is another thing to think about. PMMA usually costs less than polycarbonate. For projects that need to be very clear and pretty strong, but not super tough, PMMA is often a good choice for the money. Your material selection comes down to what you need the most. If you need the strongest plastic there is, pick polycarbonate. If you need amazing clearness, something that does not scratch easily, and a good price, then acrylic is your best bet. Both are very useful plastic materials.

One of the few bad points about regular PMMA is that it can be brittle. This means that even though it is stiff and strong, it might crack if it is hit hard or if you try to bend it too much. It does not have the same toughness as other plastic materials like polycarbonate. Because it can be brittle, regular PMMA might not be the right choice for some special used in applications. This is true if the part is going to have a lot of stress on it.

Good news, though! Scientists have found ways to make PMMA stronger. One common way is called rubber toughening. This is when very tiny bits of rubber are mixed into the PMMA while it is being made. These little rubber bits help soak up the force of a hit. This stops cracks from starting and getting bigger. This method has been used to increase the toughness of the material by a lot.

This process can increase the toughness of PMMA without making it a lot less clear. These stronger grades of PMMA are used in products that need to be both clear and long-lasting. Another way to change its features is by mixing PMMA with other acrylic polymers. This can change the material’s strength, how much it can bend, and even its glass transition temperature. The glass transition temperature is the temperature where the hard plastic starts to get soft, like rubber. Sometimes, you want a lower glass transition temperature to make it easier to shape.

You probably see and use products made from PMMA every day and do not even realize it. Because it is a material that can be used in many ways, PMMA is commonly used in a lot of different fields. At home, you can find acrylic in furniture, photo frames, and items for the kitchen. Those clear plastic boxes for storage and modern-looking chairs are often made from PMMA.

In the world of business, PMMA is often used to make signs and displays. The clear, shiny look of acrylic makes company names and letters look very clean and nice. It is also used for safety shields in stores and offices. In building, PMMA is used in the construction industry for things like skylights and big windows on buildings. Its light weight and strength make it a great material for those jobs. The car industry also uses PMMA. It is used in the automotive industry for the plastic covers on tail lights, turn signals, and pieces inside the car.

PMMA also has very important uses in medicine. It is very pure and easy to clean, which makes it a good choice for medical devices. PMMA is used to make the clear boxes that keep newborn babies warm and for equipment in labs. A special kind of PMMA is even used to make PMMA bone cement. Surgeons use this to help hold new joints in place inside the body. From cars to hospitals, the ways this polymer can be used seem to have no end.

When you pick a plastic to use outside, you have to think about how it will deal with sunlight. The sun sends out a type of light called ultraviolet, or UV, light. This UV light can hurt many kinds of plastic. It can make them get weak, brittle, and turn yellow after a while. One of the best things about PMMA is how well it handles UV light.

Regular PMMA can be outside in the sun for many years and not turn yellow or get weak. This is a big plus when you compare it to other clear plastic materials like polycarbonate. Polycarbonate needs a special UV-blocking coat on it to be used outside. Since PMMA is naturally good at handling UV light, it is a great choice for outdoor applications. This makes acrylic is ideal for things like the panels on a greenhouse, outdoor signs, and the clear covers on streetlights.

Some special PMMA grades are made with even more UV protection. These types can stop almost all of the bad UV rays from getting through. This is helpful for things like display cases in museums. There, you need to keep valuable art safe from being hurt by sunlight. This great ability to handle UV means that PMMA products will look good and stay strong for a very long time, even when left out in the weather. PMMA also has good thermal properties.

Picking the right type of acrylic for your project is very important. Your choice will be based on how much money you want to spend, what you are making, and how you will use it. The first choice to make is if you need cast or extruded acrylic. As we learned, cast acrylic is stronger and clearer but it also costs more. Extruded acrylic is a great choice that costs less for most everyday projects.

Next, think if you need any special features. There are many different grades of PMMA. Some are made to be extra strong and hard to break. Others are made to be hard to scratch. You can also find PMMA in all sorts of colors, not just clear. There are also acrylic sheets that look like a mirror and sheets that have a fuzzy or non-shiny look. You can also get PMMA that is made to spread light out evenly. This is great for making light-up boxes and signs.

Finally, think about how thick the material needs to be. PMMA sheets are sold in many different thicknesses, from very thin to very thick. A thicker sheet will be stronger and more stiff. A thinner sheet will bend more and be lighter. Make sure to look at the mechanical properties, or how strong and tough it is, for the PMMA you are thinking about. By thinking about all of these things, you can choose the right material and make sure your project turns out great. PMMA has numerous uses. PMMA has a relatively high glass transition temperature. PMMA has a low rate of soaking up water. PMMA has high strength when you pull on it.