Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

You see silkscreen printing almost everywhere. It is on clothes, posters, and even inside electronics. But how is it done? It is a printing technique where a mesh is used to move ink onto a surface, which is called a substrate. This guide explains this great printing process in a simple way. You will find out why silk screen is used so much, what it is for, and you will learn how useful it is. Reading this will help you know a lot about one of the main ways things are printed in the world.

Silkscreen printing is a very well-known way of printing. It uses a screen that is made of a woven mesh. This mesh holds a stencil. The stencil makes the shape of your design. Some parts of the screen are blocked by this stencil. This makes it so ink cannot pass through those parts. When ink is pushed through the open spots in the mesh, it puts the print on the material underneath. This easy but good way of doing things is what we call screen printing.

This method is also known as serigraphy. This name is often used when it is for making art. This printing style has been around for a long time. The main reason is because of its ability to be used in many different ways. You can print on lots of different surfaces with it. From clothes to boxes for products, commercial screen printing is a big reason things look the way they do today. It is a great way to make designs that are bold, bright, and last a long time. That is why people still use it so much.

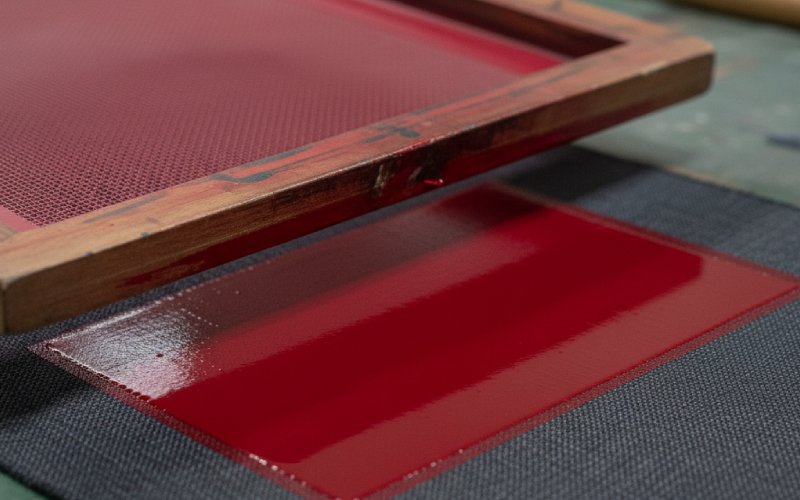

The basic silk screen printing process is simple to learn. First, you need an image or design. This design helps you make a stencil on a mesh screen. The stencil covers up some parts of the screen. Then, the screen is put on top of the material you want to print on. This material is called the substrate. A blade or squeegee is moved across the screen. This pushes ink through the open parts of the mesh. The squeegee makes a flat and smooth layer of ink. The main idea is to fill the open mesh apertures by moving it across just one time. The squeegee is moved across the open mesh apertures with ink.

When the screen springs back up, the ink is left on the substrate. This makes a very good print of the finished design on the material. Only one colour is printed at a time. If you have multi-coloured designs, you do the same steps again. You must make a new screen and stencil for every color. Since several screens can be used, you can make pictures with a lot of detail. The number of colors in your design tells you how many screens you will need.

The name silkscreen comes from a long time ago, when this skill first started. Back then, the mesh used in the process was really made out of silk. Silk was used because it was tough and was woven very tightly. But now, we have better things to make it with. Today’s screens use man-made synthetic threads. These are stronger and more exact than silk. The most common material you will see today is polyester.

Some jobs need screens that are even tougher. For those jobs, you can get special-use mesh materials. These include special-use mesh materials of nylon and even stainless steel. These materials of nylon and stainless are very tough and can be stretched very tight. This lets you print very small and clear details in the final print. There are also different types of mesh. They have a different number of threads for different kinds of printing. This choice of new materials helps printing today look much clearer than before. Artists who use this method create what is called a serigraph.

The kind of ink used in screen printing changes based on the material you print on. The thing it is used for most often is textile printing. This is for making designs on apparel like t-shirts and hoodies. For cloth, printers often use plastisol ink. This ink is thick, bright, and lasts a very long time. It makes a layer on the fabric. It must be heated to cure, which means to make it hard. Another common choice is water-based ink. This ink goes into the material itself, so it feels softer.

To print on paper, signs, or other flat things, you need different types of ink. Solvent-based inks can work on surfaces like plastic, metal, and glass. There are also special UV inks that cure right away when hit with ultraviolet light. These let you print much faster. When printing photos with many colors, printers use the CMYK process. This uses four colors of ink—cyan, magenta, yellow, and black. It can make all the colors you can imagine for graphics and text. Picking the right ink is very important for a good print.

Yes, for sure! T-shirts are the most famous thing made with silkscreen, but the process can be used on a huge variety of materials. It is used to produce all kinds of things, from posters and stickers to wooden signs and glass bottles. You can usually print on any surface that is flat. A good printer can even print on round things like cups and pens if they have the right tools. This is why screen printing offers so much value.

Companies use silkscreen to put their logo on many kinds of items for promotion. The thick, bright layer of ink gives a high-quality look that does not wear out easily. You can see this kind of printing all around you. The next time you see a bag with a design, a band poster, or even the lines on a ruler, it was probably made by a screen printer. It is a very important part of the worldwide printing industry.

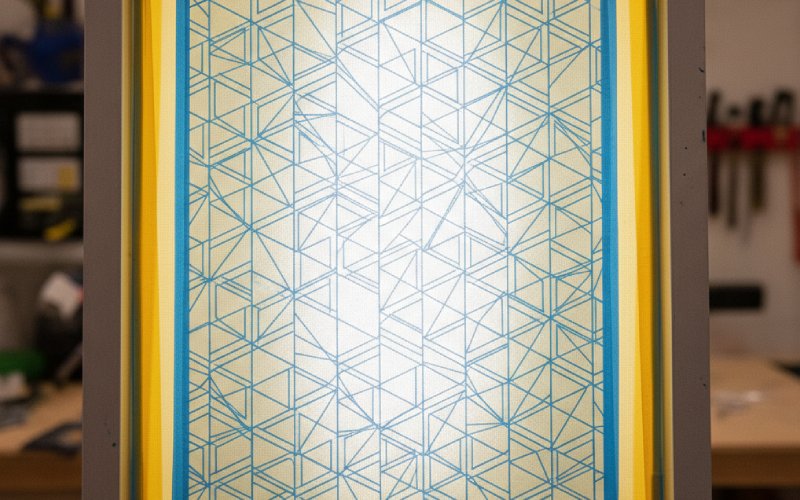

Making the stencil is the most important part of the silkscreen method. Today, we use light to do it. First, the mesh screen is covered with a special liquid that reacts to light. This liquid is called photo emulsion. After the emulsion is dry, a clear sheet with the design in black is put on top. This is a film positive. The design part is solid black, and the rest is clear.

Next, the screen is put under a strong ultraviolet light. The UV light goes through the clear parts of the sheet. It hardens the emulsion on the screen. The black ink of the design stops the light from reaching the emulsion in the shape of the original image. After this, the screen is washed with water. The emulsion that did not get hard washes away. This leaves open mesh openings in the shape of the design. This makes a perfect, clear stencil on the silkscreen so it is ready for printing.

Yes, silkscreen is a method that is very respected in the world of fine art. When screen printing is used for art, it is called serigraphy. This name helps show that it is different from printing for businesses. The well-known artist Andy Warhol used this method to make some of his most famous art, like his colorful pictures of Marilyn Monroe. He showed everyone that a business process could be used to create amazing art.

The process gives artists special control over color and feel. Every color is a different layer. Because of this, artists can make bold, flat areas of color that are difficult to create with other methods. This is why serigraphy is known as serigraphy and not just printing. It is a skill that needs practice and a good eye for art. A handmade silkscreen print is a one-of-a-kind piece of art.

It might be a surprise to you that silkscreen is a big part of making electronics. A PCB, which stands for printed circuit board, has a silk-screen layer that shows you important facts. This layer is often white ink that is printed on the green board. It does not carry electricity. Instead, it is like a guide for the people who build or fix the device.

The silkscreen on printed circuit boards shows labels for parts, logos, and safety signs. These graphics and text help builders know where every piece should go. It would be much more difficult to build electronics without this layer. The information comes from 2d technical drawings. It is put on the board with the same screen printing method used for shirts, but it is much smaller and needs to be very exact.

Silkscreen printing and digital printing are two very separate ways to print. Traditional printing like silkscreen printing needs a screen for every color. The screen is placed on the object, and a thick layer of ink is pushed through it. Digital printing is different. It is more like the printer you have at home. It sprays very small drops of ink right onto the surface to make a picture. This printing technology does not use any screens.

Each method is good for different things. Silkscreen is better when you need to make a lot of items with a simple design and not too many colors. The ink is stronger and the colors look brighter. Digital is better if you only need a few items or if your design has many colors and small details, like a photo.

| Feature | Silkscreen Printing | Digital Printing |

|---|---|---|

| Best For | Many items, simple designs | A few items, complex designs |

| Color | Bright, strong, thick ink | All colors, photo-like detail |

| How Long It Lasts | Very long, does not wear out | Good, but can lose color over time |

| Cost | Cheaper for many items | Cheaper for just one item |

| Setup | Takes time and money to start | Very quick and cheap to start |

The finishing process is the last and most important step in silk-screening. After the ink is printed on the item, it is not yet dry. To make the print stay forever, it has to be cured. The curing process uses heat. This heat locks the ink onto the material. For t-shirts, this often means they go through a big oven on a moving belt. This oven gets hotter than 300 degrees Fahrenheit. The printer needs to be sure every item gets hot enough so the ink can fully cure.

After it is cured, the print will last a very long time. The look of the finished design is bright and clear. Some printers might also do a reverse stroke. This is when the squeegee moves across again without new ink to make the print smoother. After a quality check on the printing press, the finished design is all done for the customer. This last step makes sure the print will not break, peel off, or come out in the wash.