Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Look at quotes from different CNC shops and you’ll see roughly the same pattern:

So yes, 5-axis is usually about 1.5–3× the hourly rate of a basic 3-axis.

Where does that come from?

The hourly rate isn’t just “machine time”. It’s a bundle of risk, capital, and skill.

Let’s unwrap the main cost drivers that make a 5-axis line item heavier than a 3-axis one.

A decent 3-axis vertical:

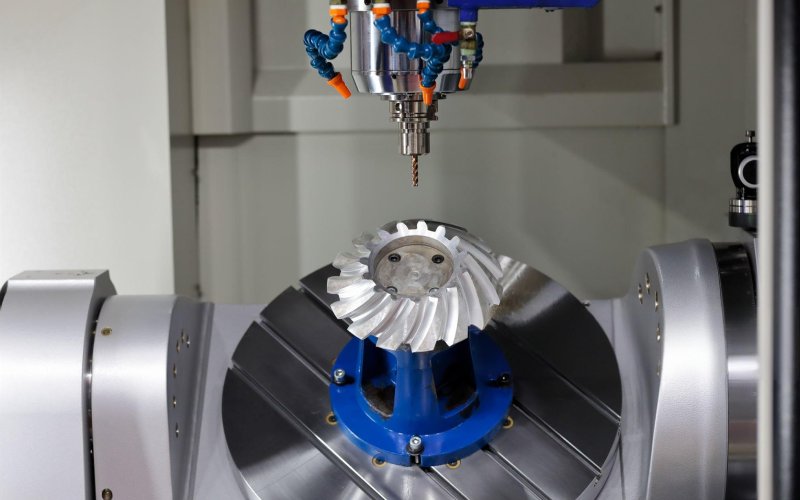

A true simultaneous 5-axis center:

That all ends up in the shop’s hourly rate model.

Even if you’re using the same CAD model, the process planning is not symmetrical:

Several cost guides explicitly note that shifting a job from 3-axis to 5-axis can double the hourly rate and significantly increase programming time.

If you see a quote where 5-axis programming is broken out, that’s why.

5-axis is supposed to save you fixtures, but ironically:

Engineers often see the fixture cost line go down and forget that metrology went up.

You don’t want an inexperienced operator learning full 5-axis on your aerospace impeller.

So shops:

That cost isn’t labeled, but it’s inside the rate.

Let’s take a simplified example:

One realistic way to look at it:

| Item | 3-axis machining | 5-axis machining |

|---|---|---|

| Typical machine rate (shop) | $40/hour | $90/hour |

| Number of setups | 4 | 1 |

| Setup time per batch | 2 h (0.5 h × 4 setups) | 1.2 h |

| Average cycle time per part | 16 min (4 min × 4 faces) | 9 min (all faces in one go) |

| Fixture cost (one-time) | Higher – multiple custom fixtures | Lower – simple 5-axis workholding |

| Operator touch time | More – repeated loading and alignment | Less – single clamp |

| Scrap risk (re-clamp errors) | Higher | Lower |

| Effective cost per good part | Often similar, sometimes higher | Often similar, sometimes lower |

The interesting thing:

Even though the 5-axis hourly rate is more than double, by the time you:

…the total cost per part can converge, or sometimes tilt in favor of 5-axis for the right geometry.

This is why a simple “5-axis is more expensive than 3-axis” statement is only half true. Hourly rate and piece price are not the same story.

From a procurement desk, it often looks like this:

“The part has simple flats and holes. Why is the supplier insisting on 5-axis and charging more?”

A few reasons, none of them mystical:

So no, suppliers aren’t always “overselling” 5-axis. Sometimes they are simply optimizing their own factory economics, not yours.

For engineers and purchasing teams, it helps to think in triggers, not in axes.

Situations where 5-axis usually justifies the higher rate:

In short: if the part geometry forces additional processes on 3-axis (extra fixtures, EDM, manual finishing), 5-axis starts to look less “expensive” and more “compressed”.

When you’re choosing machining strategy or talking to suppliers, these checks help:

You can probably stay with 3-axis if:

You should seriously consider 5-axis if:

And a middle ground:

Ask suppliers explicitly whether the quote assumes 3+2 or full 5-axis motion. Many buyers don’t, and it matters.

Instead of just asking “Can you run this on 3-axis instead?”, try these more concrete questions in your RFQ:

These questions shift the conversation from “5-axis is expensive” to “what process makes economic sense for this part and this volume”.

Typical ranges reported by machining providers:

3-axis: about $30–$60 per hour in many regions.

5-axis: roughly $70–$120+ per hour, with high-end systems going well beyond that for special work.

The ratio matters more than the absolute numbers, since labor and energy costs differ by country.

No.

Even though the hourly rate is higher, 5-axis can:

Cut setups

Shorten cycle time

Reduce scrap and rework

Remove secondary processes like EDM or manual finishing

For complex parts, total cost per part can be similar or lower than a 3-axis route.

Because:

Toolpaths are more complex and collision-sensitive.

Simulation and verification are more extensive.

Post-processing and machine-specific tuning take longer.

That extra engineering time is spread across the quantity you order. For very low volumes, you feel it more.

Not automatically.

Ask:

Is 5-axis chosen due to capacity, not geometry?

Would 3-axis require fixtures that make the job more expensive overall?

Are they planning for future revisions?

If they can’t give a clear process reason, then yes, it may be worth getting a comparison quote from another shop.

Keep datums and tolerances realistic and avoid linking many faces unless necessary.

Avoid “cosmetic” angles and features that force extra setups or axes.

Mark which surfaces are truly critical and which are flexible.

That way, your supplier has room to choose the most economical process instead of being forced into 5-axis by ambiguous requirements.