Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

A tolerance is a super important note on your drawing. If you get it wrong, it can make you lose time and money. This guide to CNC machining will make understanding tolerances easy to learn. I will show you how to choose the correct tolerance for your part. This will help you get good parts from any CNC machine without spending too much money. Reading this will help you get better parts and save money.

A tolerance is the amount of difference that is okay for a part’s size. It is the okay difference from the size on the drawing. No machining process is completely perfect. A CNC machine is wonderful, but it cannot make a part that is exactly 10.0000 mm each time. There will always be a tiny difference from the perfect size. This small, okay difference is the tolerance. This is the main idea of tolerance in CNC machining.

You can think of a tolerance as a safe zone for a size. Let’s say you need a pin that is 10 mm wide. You could add a tolerance of ±0.1 mm. This tells the machinist that the final machined part can be any size from 9.9 mm to 10.1 mm wide. Any pin made in this size range is a good part. The tolerance shows how much precision is needed. This tolerance is a very important part of every drawing. The final part’s dimension must lie inside this range to be good.

Think about a jigsaw puzzle. The pieces will not fit together if they are not the right size. A machining tolerance works in the same way for a machined part. It makes sure that parts fit and work together in the right way. If you are building an engine, a piston needs to fit inside a cylinder just right. A small error in the machining tolerance could cause the engine to break. That is why we specify a machining tolerance for every important dimension.

The correct machining tolerance makes sure parts work well and are good quality. A part with the wrong tolerance could be too loose and shake. Or, it could be too tight and not be able to move. Getting the tolerance correct is a huge part of making things with precision. It is how we make sure of the dimensional accuracy for every machined part we create. A good machining tolerance is the key to making a product you can count on. It is a promise that your parts will work the way you planned. This is a main part of all engineering tolerances.

When I first started, I believed there was only one kind of tolerance. But there are a few ways to write them down. This is called tolerancing. The one used the most is a bilateral tolerance. This means the change can go in two directions, which are plus and minus. For instance, 10 mm ±0.1 mm is a bilateral tolerance. The dimension can be 0.1 mm larger or 0.1 mm smaller.

There is another kind called a unilateral tolerance. With a unilateral tolerance, the change can only go in one direction from the main size. You might see it on a drawing as 10 mm +0.2/-0.0 mm. This means the part can be as large as 10.2 mm, but it can’t be any smaller than 10.0 mm. We use a unilateral tolerance when we need to make sure a part is never too small. We also have limit tolerance, where you just write the largest and smallest sizes allowed, like “9.9 mm – 10.1 mm”. This shows the clear upper and lower limits. This tolerancing way is very clear, as the tolerance is expressed as a range. The unilateral change is on just one side of the nominal size.

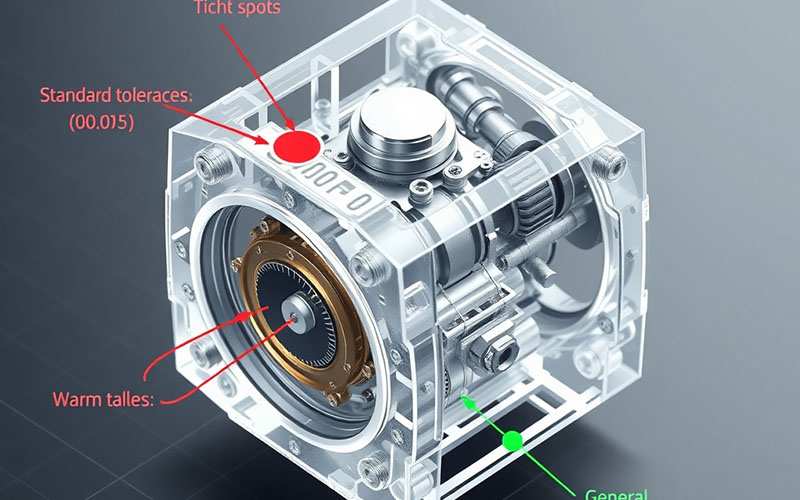

Most machine shops have a tolerance they use all the time that they can hold without doing anything special. This is often called a standard tolerance or standard cnc machining tolerances. If you do not write a certain tolerance on your drawing, the shop will use its standard one. This often follows an international standards system like ISO 2768. This standardized tolerances system gives a simple machining tolerance for parts made on a CNC machine.

The ISO 2768 standard has a few different classes, like fine, medium, and coarse. The “medium” class is used a lot for standard prototype and production machining. For a metal part that is 30 mm long, the ISO standard might say the standard tolerance is ±0.2 mm. These are seen as typical tolerances. Using a standard CNC tolerance is a very good way to save money. It means the shop does not need special tools or setups. You should only ask for a tighter tolerance when you really need it.

A cnc machining tolerance chart can look hard to understand, but it is very useful. This chart helps you see what a common tolerance is for a certain size or machining process. It will have lines for different size groups, like 0-6 mm, 6-30 mm, and 30-120 mm. The columns will show a different tolerance grade. This tells you what is simple and what is difficult for jobs like CNC milling or CNC turning.

For instance, you could look at the chart for a 50 mm hole. The chart might tell you a standard CNC machine can easily hold a tolerance of ±0.05 mm. But to get a tighter tolerance of ±0.01 mm may require a special tool. The chart could also be different for different materials. This specification helps you pick a machining tolerance that will work and also save money. It is a great tool for handling your tolerance requirements.

Here is a simple example:

| Part Size (mm) | Standard Tolerance (± mm) | Tight Tolerance (± mm) |

|---|---|---|

| 0 – 10 mm | 0.10 mm | 0.025 mm |

| 10 – 50 mm | 0.15 mm | 0.050 mm |

| 50 – 120 mm | 0.20 mm | 0.100 mm |

This table shows that when the dimension of the part gets larger, the standard tolerance also gets a bit larger. A small tolerance on a big part is very hard to make.

There are times when a plus/minus tolerance for a dimension is not enough information. We also need to control the shape, place, or angle of a part or a detail. This is where Geometric Dimensioning and Tolerancing (GD&T) helps. I like to think of GD&T as a special language for engineers and the people who run the machines. It uses symbols on drawings to give special instructions. This is a key part of dimensioning and tolerancing.

GD&T tolerances use special controls. For example, a true position tolerance tells the machinist the perfect spot where a hole must be. A datum is a starting point that we measure from. Another example is concentricity. The concentricity tolerance makes sure two circle-shaped parts share the very same center. GD&T helps us explain these geometric connections. This kind of geometric dimensioning is set by groups like the American Society of Mechanical Engineers. It also includes things like profile tolerances to control the shape of a surface.

I am asked this question often. When should you specify tight tolerances? My answer is easy: only when you really have to. Tight tolerances are needed for parts that spin at high speeds or fit together in a perfect way. Think about bearings inside a motor. These parts need to be super exact. A good CNC machining service can make parts with this precision, but it will cost you more money.

Before you ask for tighter tolerances, you should ask yourself if the part will work with a looser tolerance. A simple cover for a box probably does not need a really tight tolerance. Its dimension can be a little off and it will still work fine. Asking for non-standard tolerances means the CNC machining service must work much harder. This could mean using a different machining technology to achieve the desired part, special measurement tools, or having more bad parts. You should always talk with your CNC machining service provider. They can help you figure out if a tolerance is really needed.

Here is a helpful tip that will save you money: tolerances can increase your costs very quickly. The connection between cost and tolerance is not straight-forward. Making a tolerance two times tighter could make the part four times more costly. This is a key part of choosing tolerances. Each time you make a tolerance smaller, you add more work for the person running the CNC machine.

Your goal is to find the optimal tolerances. These are the loosest tolerances that still let your part work correctly. This is how you find the appropriate tolerances for your project. A looser tolerance means the machinist can run the CNC machine at a faster speed. They can use a normal cutting tool. They will also spend less time checking each machined part. This will save both time and money. My personal rule is to begin with a standard tolerance. I only make it tighter on parts that need very high precision.

This is a harder topic in tolerancing, but it is good to know about. Maximum Material Condition (MMC) and Least Material Condition (LMC) are ideas that come from GD&T. They connect the size tolerance of a part to its position tolerance. Think of a hole in a flat piece of metal. The maximum material condition is when the hole is at its smallest allowed size. This is because the most amount of metal is still left in the part. In this case, machining refers to cutting away material to make a part with specific dimensions and tolerances.

The least material condition is the other way around. It is when the hole is at its biggest allowed size. Why is this important? You can sometimes give the machinist an “extra room” tolerance. If they make the hole bigger than the maximum material size, you can let them have more error in where the hole is placed. This gives them more room to work. It can make the machined part easier and cheaper to build. This specification is a smart way to control how parts fit with each other.

We have talked about a lot of things. It might seem like a lot to remember. When you think about things related to cnc machining, your most important job is to talk in a clear way with the machinist. Your drawing is how you talk to them. Your use of tolerance and CNC tolerances is the most important part of that talk. The tolerance controls you specify are your directions.

You need to specify the correct tolerance for each part. This means you must think about how parts will fit with each other. Does this surface touch another part? If the answer is no, then you should use a standard machining tolerance. If the answer is yes, you might need a tighter one. But you should always think about the cost. Good engineering is not about making everything perfect. It is about making things that work well for a fair price. Understanding part tolerances and general tolerance in cnc machining is the key to doing that.