Let Istar help you get started on your project with our experience and know-how!

Upload your design files and production requirements and we will get back to you within 30 minutes!

Zinc die casting is a huge help in the industry that makes things. In this article, I am going to explain what zinc die casting is. I will also explain how it works. You will see why it could be the best pick for your next job. This article is for you if you want to make strong parts with a lot of detail. And it will show you how to do it fast and for a good price.

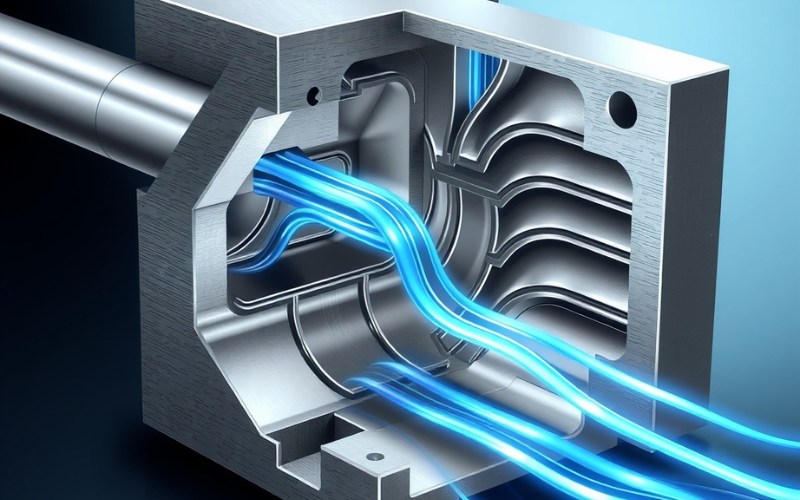

So, what is this process that I am so happy to talk about? The zinc die casting process is a method for making metal parts. You can think of it like making a waffle. You use a special metal mold. We call this mold a “die.” This mold is made in the perfect shape of the part you want to make. The first thing you do in this type of casting is melt a special metal. This metal is called a zinc alloy. After the zinc alloy becomes a hot liquid, a machine pushes it into the mold. It uses a lot of pressure.

The liquid metal goes into every small space inside the mold. Next, it cools down very fast. It turns into a solid part, which is a new casting. After just a few seconds, the machine opens the mold. The finished casting is then pushed out. This full process of casting can be done hundreds or even thousands of times every hour. It is a very fast way of making things. It is also very exact. This modern process of die casting makes a very strong casting with a smooth finish. This is a very big plus. This casting process is a well-liked choice in many parts of the industry. The process of die casting originally started a long time ago, but it is very advanced now.

The best thing about this casting method is how exact it is. The molten metal is pushed into the mold with pressure. Because of this, the final casting shows every little detail of the mold design. This means you can create shapes that are not simple. You can make shapes that would be hard to make with other casting processes. We say it has good “castability.” This specific casting method is great for making parts in building and industrial fields. The finished casting has very exact sizes, which means it is very accurate in its shape and measurements. The whole casting process is set up for speed. It is also set up for making something over and over, which makes it great for creating many parts that are the very same.

People often ask me why they should pick zinc die casting. There are many different casting processes to choose from. So, what makes this one special? The big reasons are speed, being very exact, and the great quality of the final casting. When you compare it to other casting processes like sand casting or investment casting, zinc die casting is much, much quicker. The fast time it takes to make one part means you can produce a large number of parts in a short amount of time. This speed makes each part cost less, which is a big advantage.

Another reason I like this casting process is that the mold lasts a long time. The zinc alloy used in this casting has a low melting point. This is key because it means the steel mold does not get as hot. It does not get worn out as much as it would with metals like aluminum. This means the mold can last for more than a million uses before you need a new one. Other casting processes, like aluminum die casting, wear out the mold much more quickly. A mold that lasts longer means you spend less money on molds during the project.

Last, the quality of the casting right after it comes out of the machine is wonderful. Parts made from this casting process have a very smooth surface finish. They usually do not need much more work, like polishing or sanding. This saves time and money in the process of making the part. Many other casting processes leave a rough surface. That rough surface needs a lot of work to get a nice finish. For any designer who needs parts that look good, zinc die casting is a great choice. This casting process is known for its amazing finish.

When people talk about zinc die casting, they are usually talking about the hot chamber die casting process. I think this process works very well and fast. In a hot chamber machine, the pot that melts the zinc alloy is a part of the machine. The system that pushes the metal is under the liquid metal. This is not like a “cold chamber” process. In that process, the metal is melted somewhere else. Then it is carried to the machine for each part.

Here is how this great casting process works. A part called a plunger pulls back, and a small door opens. This lets the liquid zinc alloy go into a space called a “gooseneck.” Then, the plunger pushes forward. It closes the door and forces the liquid metal out. The metal goes through a nozzle and into the mold with a lot of pressure. Because the metal is already in the machine, the process is very quick. The hot chamber process is a good fit for alloys with a low melting point, like a zinc alloy. This makes the whole die casting production system move very fast.

The speed of the hot chamber process is a big reason why zinc die casting makes so many parts so quickly. You do not lose time moving liquid metal from a heater to the machine. The whole thing is all in one place and works by itself. This means it takes less time to make each part. It also means less material is wasted. And you have a better-controlled environment for casting. This control helps make sure that every casting is the same and has high quality. This is why the hot chamber die casting process is used for almost all zinc alloy die casting jobs.

I could talk all day about the good things that come from zinc die casting. It is a process that gives you a great mix of strength, being exact, and giving you good results for the money you spend. When a customer needs a part that lasts a long time and has small details, this is usually the first casting method I suggest. The physical and mechanical properties of the zinc alloy are just that good for this type of casting.

Let’s look at some of the main benefits.

I get this question all the time. Both zinc alloy casting and aluminum die casting are great processes. But they are a good fit for different kinds of things. It is not about one being “better.” It is about which one is right for your part and your industry. I have used both casting processes for many jobs. Here is a simple chart I use to help my customers decide.

| Feature | Zinc Alloy Casting | Aluminum Die Casting |

|---|---|---|

| Melting Point | Lower (around 728°F / 387°C) | Higher (around 1220°F / 660°C) |

| Mold Life | Very Long (1 million+ uses) | Shorter (around 100,000 uses) |

| Speed per Part | Faster (uses hot chamber machine) | Slower (uses cold chamber machine) |

| Part Detail | Excellent (can make very thin walls) | Good (walls need to be thicker) |

| Surface Look | Very Smooth | Good, but often needs more work |

| Strength for its Weight | Good | Excellent (aluminum is a lighter metal) |

As you can see, a zinc alloy gives you big benefits in how fast you can make parts and how long the mold lasts. This is because of its low melting point. If you need to make a lot of small, detailed parts that look beautiful, zinc die casting is often the choice that saves you more money. But if how much the part weighs is the most important thing, then aluminum alloys might be a better pick. This is true even if the casting process is a little slower and the mold does not last as long. The choice between these casting processes is based on what is most important for your cast parts.

After you have chosen zinc die casting, the next thing to do is pick the right zinc alloy. Not all zinc alloys are the same! They are like different recipes. Each one has its own special features. The most common group of zinc alloys is called Zamak. The name is from the German words for the metals in the alloy: Zink (zinc), Aluminum, Magnesium, and Kupfer (copper).

The most well-known zinc alloy in the world is Zamak 3 (also known as Alloy 3). I suggest it for about 80% of casting jobs. It has a great mix of strength, flexibility, and how easy it is to cast. It is a good zinc alloy for general use. It is easy to work with and gives a great finish. Another common one is Zamak 7 (Alloy 7), which has more flexibility. This makes it a good fit for parts that need to be bent or shaped after casting. The zamak family of zinc alloy can be used for many things in casting.

Then there is another group of zinc alloy called ZA alloys. These have more aluminum in them. ZA-8 is a good pick if you need something with better hardness that wears down less than the Zamak alloys. ZA-27 is the strongest of all the zinc alloys. Its yield strength can be as strong as some types of steel. But these ZA alloys can be a little harder to use in the casting process. The right choice of zinc alloy is based on what you need the part to do. Do you need it to be very strong? Do you need it to be flexible? Do you need it to be very hard? The company that makes your parts can help you choose the perfect zinc alloy for your casting project.

The automotive industry uses a very large number of zinc die cast parts. I have worked on many jobs making parts for cars. There is a good reason this industry loves zinc alloy die casting. Cars need parts that are strong, last a long time, and look good. This casting process gives them all three things. Cars are made in very large numbers. So, the speed and good work of the casting process are also a very big benefit.

You can find zinc die cast parts in many places on a new car. A very common application is for door handles, window cranks, and parts for locks. These parts must be strong enough to be used thousands of times. They also need a high-quality finish, like chrome plating, to look nice for the whole life of the car. Zinc die casting makes the perfect smooth surface for a high-quality plating job. The long life of a zinc alloy casting is perfect for the automotive industry.

Other examples of automotive zinc parts are emblems, logos, and parts for seatbelt systems. The casting process allows for the small details needed for a company logo. For safety parts like a seatbelt lock, the high strength and impact strength of a zinc alloy is very important. The fact that the casting does not rust easily is also a big plus. Car parts are in a tough environment with rain, snow, and salt. The automotive industry knows it can count on this manufacturing process.

One of the best things about using a zinc die cast part is how simple it is to add a finish. The casting process makes such a smooth surface that it is ready for a coating. It needs very little work before the coating. This saves a lot of time and money when making parts. There are many finishing options you can choose. They can make the part look better or add even more protection to the already very good anti-corrosion zinc properties.

Here are some of the most popular finishing options I have used on a zinc casting:

These finishing options give a designer a lot of choices. You can take a strong, exact zinc die cast part and make it look almost any way you want. Being able to do many different things is a big benefit of using zinc for your casting needs.

Picking the right company to make your parts is one of the most important things in any casting job. A good company is like a partner who will help you get the best part you can. A bad company can cause problems with timing and quality, and give you a headache. Over many years, I have learned that a low price is not the most important thing. How much they know and the quality of their work are what truly matter.

When I am looking for a new zinc die casting supplier, I check for a few important things. First, I want to see their history. How long have they been in the industry? What kinds of parts have they made in the past? I ask to see examples of their casting work. A good company will be happy to show you their quality. I also ask about how they do their mold design. The mold is the most important part of the casting process. A mold that is designed well is needed to make a good part.

Second, I look at their process for checking quality. How do they make sure every casting is made correctly? Do they have new tools to check the parts? A good supplier will have a clear way to check parts at every step. They will check from the raw zinc alloy to the final, finished casting. Last, I talk with them. Talking and sharing information is very important. A good supplier will listen to what you need. They will give you helpful ideas. And they will let you know how your job is going. Finding the right supplier is a very important step for a good zinc die cast manufacturing experience.

Yes, it really can. This is one of the main reasons why the zinc die casting process is so well-liked in so many industries. When you look at the full cost of making a part, this casting method is often the one that saves you the most money. This is especially true when you are making a lot of something. The savings come from a few different parts of the manufacturing process.

First, the process itself works very well and fast. The hot chamber machine runs at a high speed. It makes more parts every hour. This reduction in time for each part lowers the cost of paying workers for each part. The low melting point of the zinc alloy also means less power is used to melt the metal. This lowers the cost of electricity. The process also makes very little material that is wasted. Any extra metal can be easily melted again and used. This is good for the cost of production and for the environment.

Second, the long life of the mold creates huge savings. With other casting processes, you might have to pay for new molds or for fixing molds while you are making your product. With a zinc die casting mold that lasts for a million or more uses, you often need only one mold for the whole time you are making the product. Finally, the great surface finish of the casting saves money on extra steps. You spend less time and money on polishing, sanding, or other work before the final finish is put on. All of these things together make zinc alloy die casting a very smart choice for your budget.

I have talked about many things related to zinc die casting. It is a process with a lot of power that can be used for many things. To finish up, here are the most important points to keep in mind: